Bearing type passenger car chassis assembling, welding, overturning, transferring and splicing integrated tool

A load-bearing, tooling technology, applied in transportation and packaging, auxiliary devices, workshop equipment, etc., can solve the problems of low production efficiency, low dimensional accuracy, and large site occupation area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

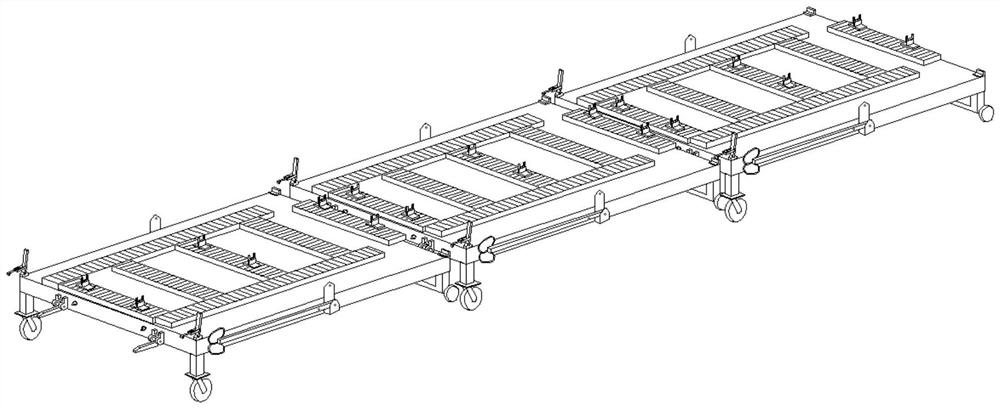

[0059] like figure 1 As shown, the embodiment of the present invention provides a load-bearing bus chassis assembly welding, turning, transfer and assembly tooling, including a plurality of independent tooling, each independent tooling includes a channel steel welding frame 5, a channel steel The welding frame 5 is internally welded with a base surface 3, and the upper surface of the base surface 3 is detachably connected with a plurality of T-slot table tops 2 through bolts. Some T-slot table tops 2 are fixedly connected with positioning block 1 by bolts, and positioning block 1 is fixedly connected with T-slot table top 2 by bolts. The location is suitable for different vehicle types; the left and right sides of the base surface 3 are respectively fixed with a rope-type chassis turning device 12, which is used to realize the turning of the chassis.

[0060] Further, the base surface 3 is provided with a plurality of through holes for easy cleaning.

[0061]The number of in...

Embodiment 2

[0065] This embodiment is based on embodiment 1, as attached image 3 , attached Figure 4 As shown, the guide positioning mechanism includes a guide plate 61, the guide plate 61 is hinged with the left side of the channel steel welding frame 5 of the independent tooling through a rotating shaft, the guide plate 61 is a horizontal rotary guide plate 61, when not in use The guide plate 61 is horizontally rotated until the lower surface of the channel steel welded frame 5 is hidden, and it is horizontally rotated to as attached when in use. figure 1 The shown position cooperates with another adjacent independent tooling to play a guiding role; the top of the guide plate 61 is also provided with a positioning plate 62 for cooperating with it. The positioning plate 62 includes an arc segment and a straight arm segment, and the arc segment passes through the fifth arm. The rotating shaft is hinged on the side wall of the channel steel welded frame 5, and the straight arm section i...

Embodiment 3

[0070] This embodiment is based on Embodiment 1. The rope-type underframe turning device 8 includes a second base 81, a column 82, a hook 83 and a limiting element 84; the second base 81 is fixed on the channel steel welding frame 5 On the side, the upper end of the column 82 is fixed with a hook 83, and the lower end of the column 82 is hinged with the second base 81 through the fourth rotating shaft. And the column 82 is used to limit the rotation of the column 82 .

[0071] In the rope-type underframe overturning device 8 provided by the present invention, the fixing bolts are selected for the limiting element 84. When using the rope-type underframe overturning device 8, the upright column 82 is first rotated, and the upright column 82 will be used to fix the load-bearing type after it is rotated to a vertical position. One end of the rope of the passenger car chassis is fixed on the load-bearing bus chassis, and the other end is fixed on the hook 83. At this time, the thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com