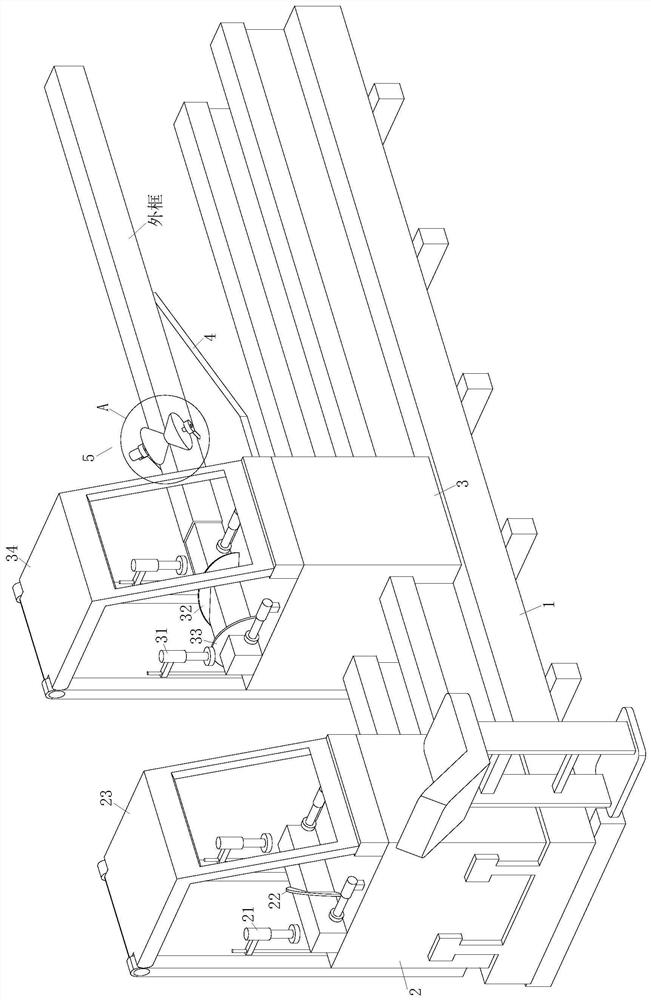

A three-head saw for processing aluminum alloy door frames

A technology of aluminum alloy and outer frame, which is applied in the field of three-head saws, can solve problems such as inability to guarantee angle accuracy, narrow cutting angle range, and cumbersome process, and achieve the effects of preventing potential safety hazards, improving the scope of application, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

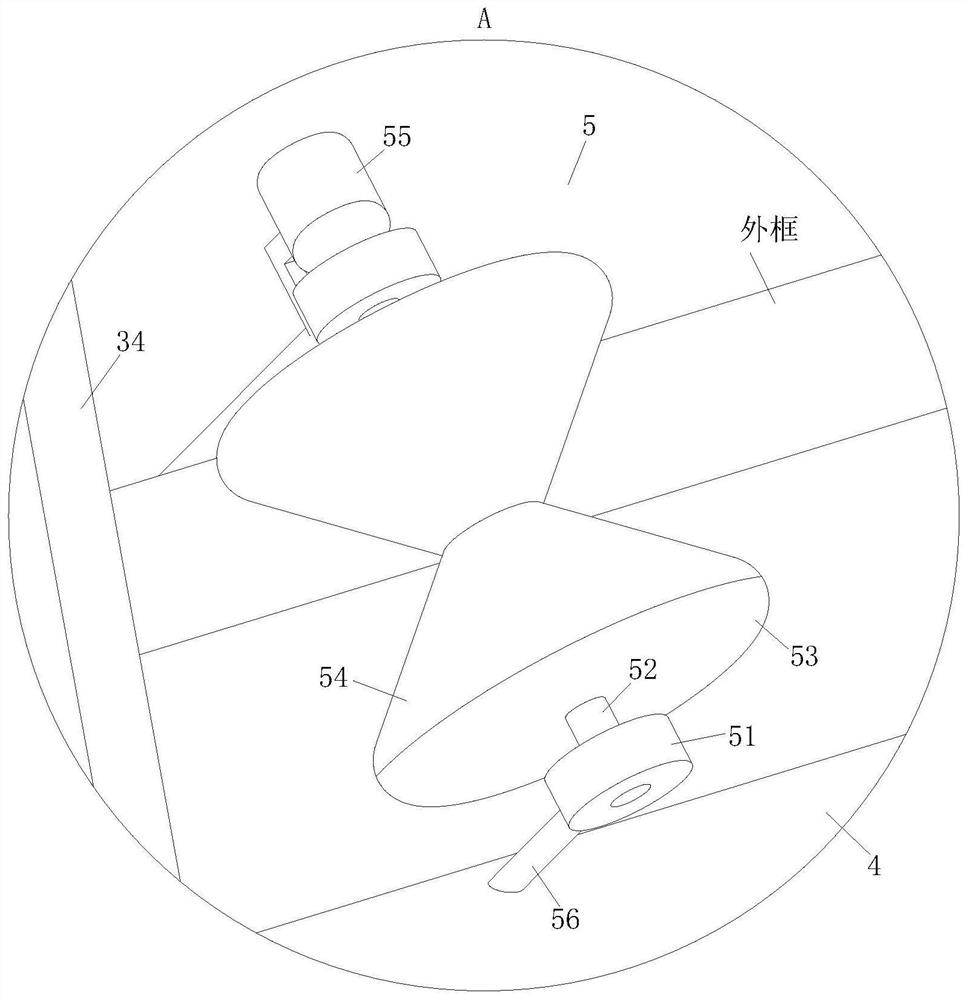

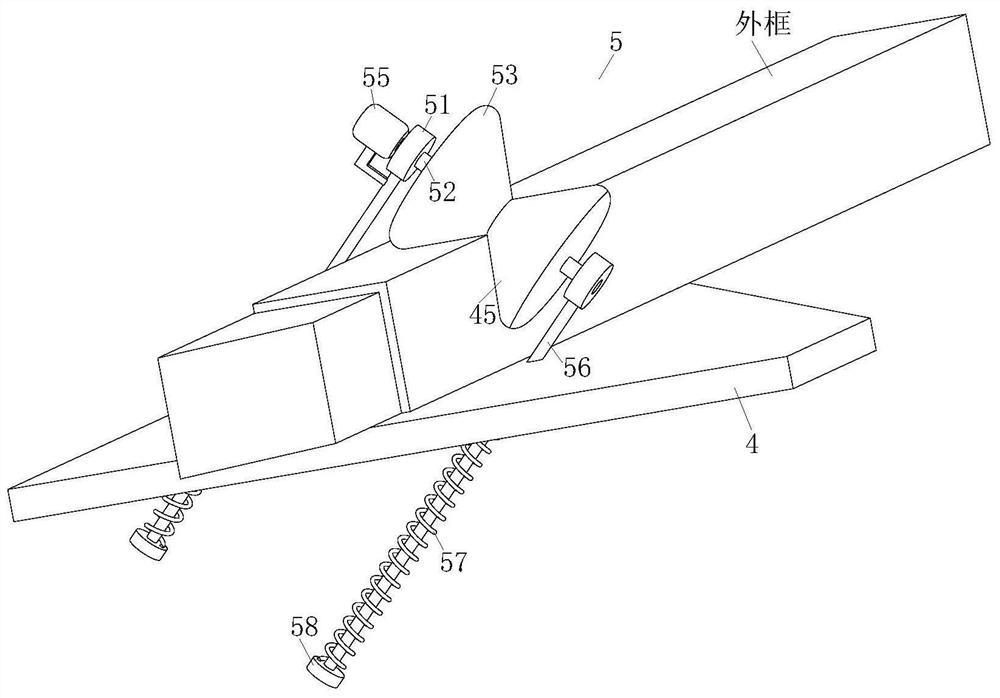

[0033] As an embodiment of the present invention, a stopper 59 is fixedly connected to an end surface of the support plate 51 close to the roller 53; a round groove 531 is provided on the side of the roller 53 facing the support plate 51; the circular groove 531 is slidably connected Next to the slider 532, a second spring 533 and a pressure sensor 534 are also provided in the circular groove 531; the pressure sensor 534 is located at the bottom of the circular groove 531; one end of the second spring 533 is connected to the pressure sensor 534, and the other end The slider 532 is connected with the slider 532; the slider 532 can be driven by the roller 53 to contact the stopper 59; during work, the outer diameter of the roller 53 is constant, so the rotation angle of the roller 53 can be used to calculate the outer diameter driven by the roller 53. The moving distance of the frame will drive the slider 532 to move during the rotation of the roller 53, and the moving slider 532...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com