Efficient crushing sand making machine with novel lining plate

A technology of sand making machine and lining plate, applied in grain processing and other directions, can solve the problems of low crushing efficiency of crushing sand making machine, and achieve the effect of prolonging crushing time and high crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

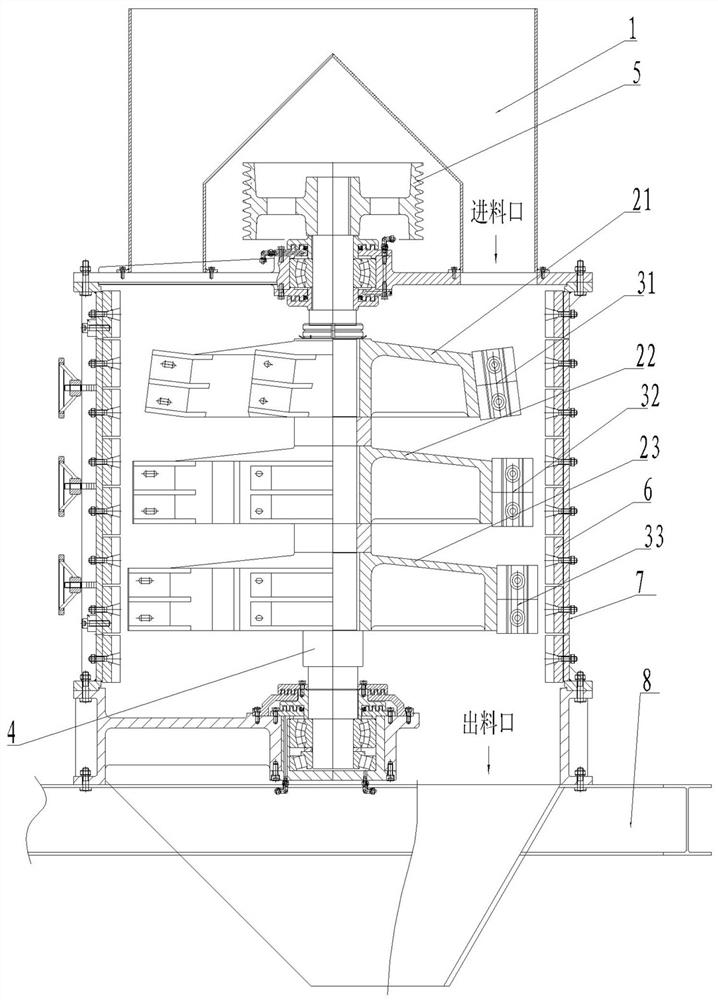

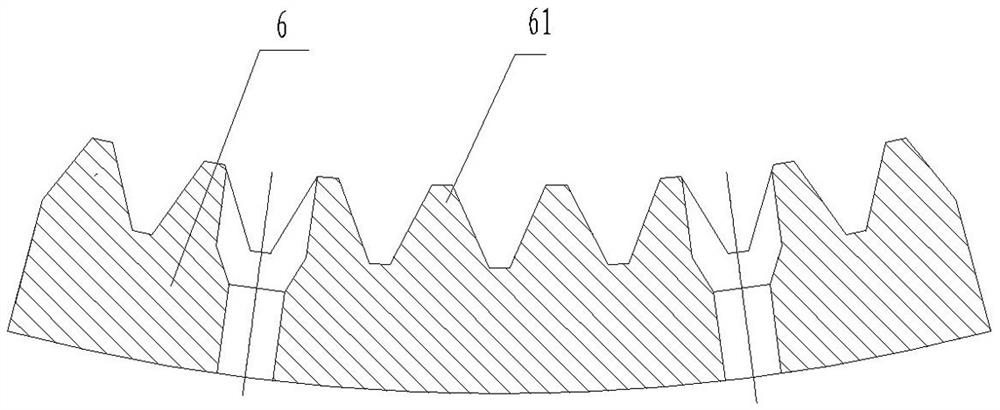

[0020] A high-efficiency crushing sand making machine with a new type of liner, including a lower hopper 1, a hammer body, a hammer head, a rotating shaft 4, a pulley 5, a liner 6, an outer cylinder 7, and a base 8. The lower hopper 1 is installed on the base 8 through the outer cylinder 7, the rotating shaft 4 is installed in the outer cylinder 7 through the rotating shaft seat, the belt pulley 5 is located at the lower hopper 1 and is installed on the upper end of the rotating shaft 4, and the liner 6 is installed on the inner wall of the outer cylinder 7. The hammer body includes an upper hammer body 21, a middle hammer body 22, and a lower hammer body 23, and the upper hammer body 21, the middle hammer body 22, and the lower hammer body 23 are sequentially installed on the rotating shaft 4 from top to bottom; the hammer head includes an upper hammer head 31 , Middle tup 32, following tup 33, upper tup 31, middle tup 32, following tup 33 are respectively installed on the upp...

Embodiment 2

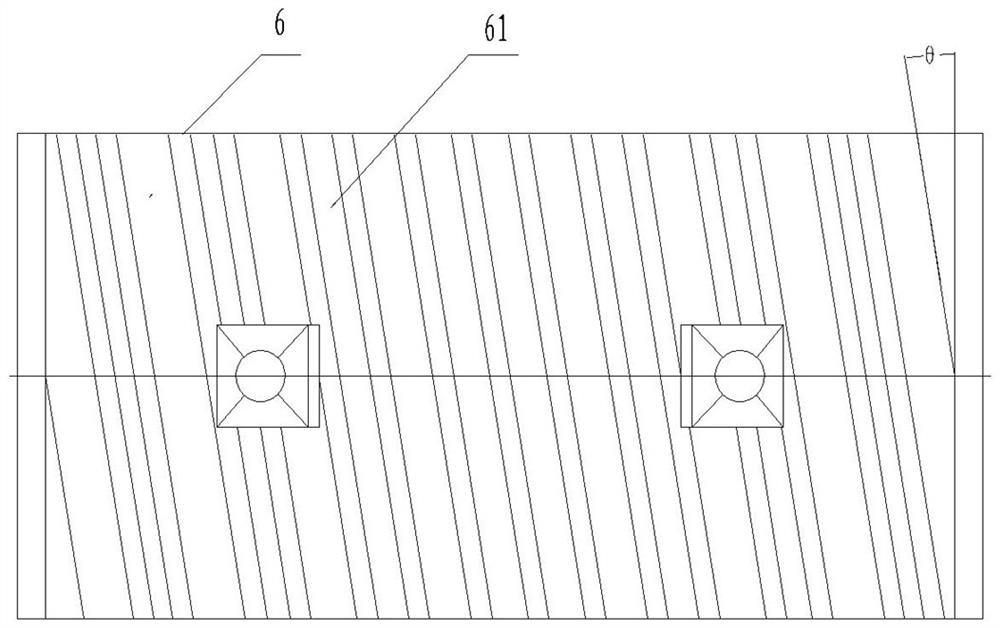

[0024] A high-efficiency crushing sand making machine, the tooth 61 of the liner 6 rotates in a left-handed direction, and the tooth rotation angle θ is 6°. The ratio A between the arc length and the height of the liner 6 is 2; the ratio B between the height and the thickness is 1.5; the rest of the structure is the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com