Waste treatment device for civil engineering and treatment method thereof

A technology for waste treatment and civil engineering, applied in grain treatment, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as poor crushing effect, and achieve the effect of easy transportation, easy recycling, and improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

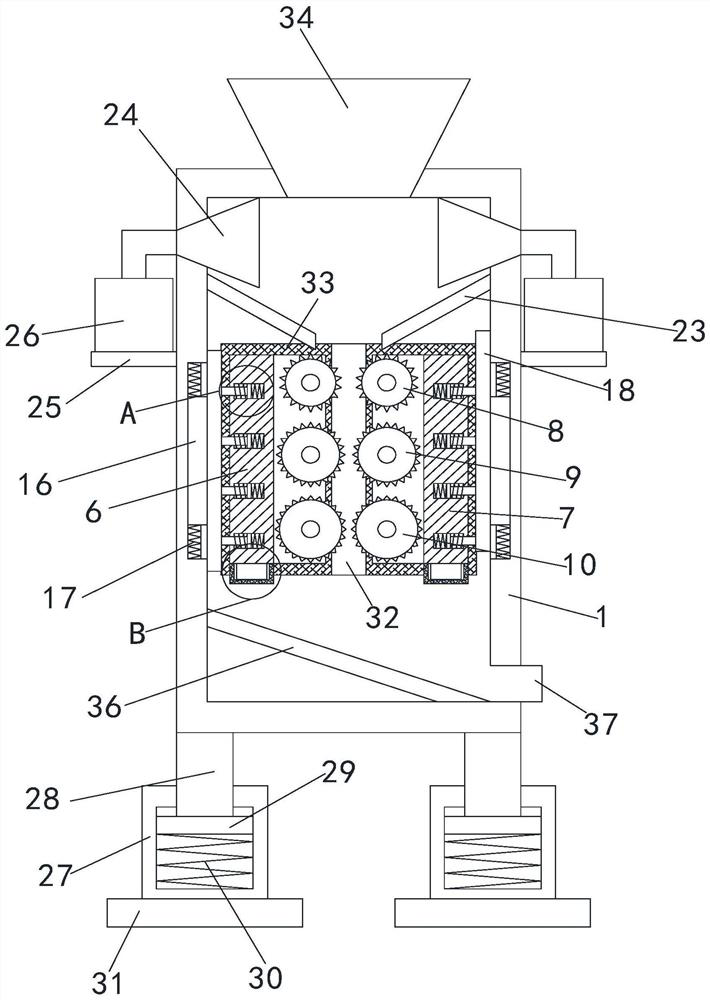

[0031] see Figure 1-5, a waste treatment device for civil engineering, comprising a crushing box 1, the front end and the rear end of the crushing box 1 are provided with a through groove penetrating to the inside of the crushing box 1, the outer side of the through groove is provided with a first chute, two through The inner left side and the right side of the groove are respectively provided with a first sealing plate 2 and a second sealing plate 3, the first sealing plate 2 and the second sealing plate 3 are all slidingly matched with the first chute, the first sealing plate 2 and the second sealing plate The first elastic rubber 4 is connected between the two sealing plates 3, so that the first sealing plate 2 and the second sealing plate 3 shake with the first crushing block 6 and the second crushing block 7, and the first sealing plate 2 and the second sealing plate The outside of the plate 3 is fixedly connected with a plurality of first springs 5, and one end of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com