Feed processing and stirring device uniform in discharging

A feed processing and stirring device technology, which is applied to mixers with rotating stirring devices, feed, mixer accessories, etc., can solve the problems of high work intensity, time-consuming and laborious, and low labor cost, and achieve the effect of high stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

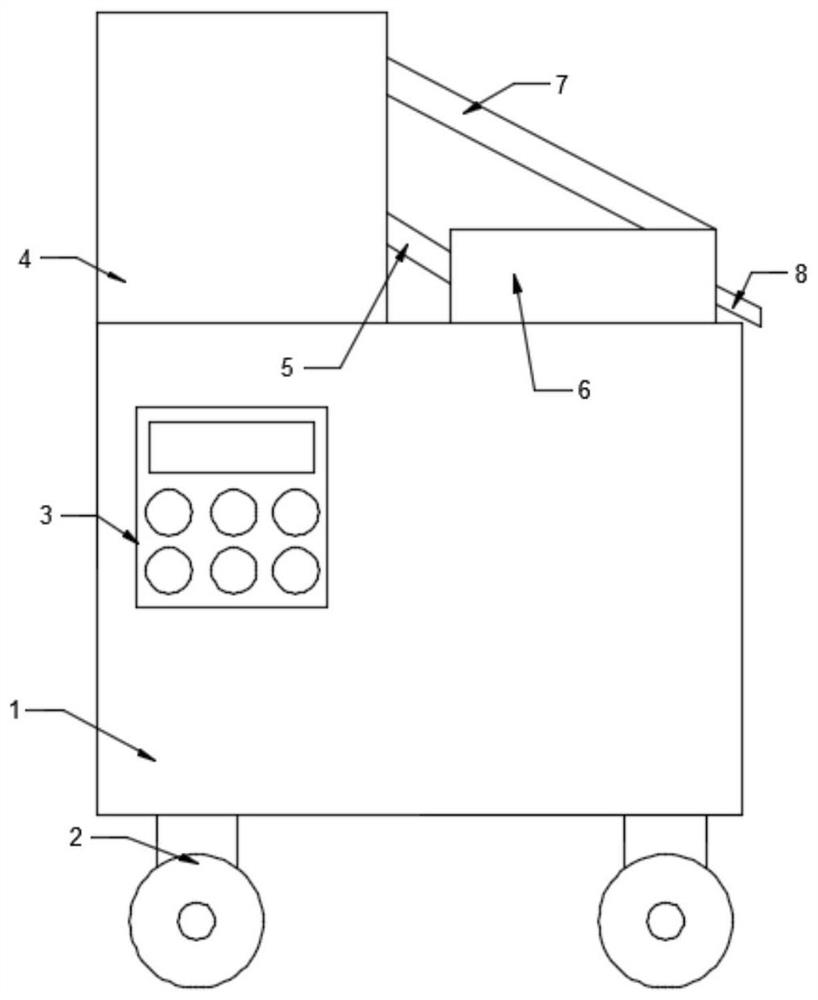

[0030] see Figure 1-8 , in an embodiment of the present invention, a feed processing and stirring device with uniform discharge includes: a box body 1, a universal wheel 2 is installed at the bottom of the box body 1, and a wall plate on one side of the box body 1 is provided with Control panel 3, a stirring mechanism 4 is fixed on one side of the top of the box body 1, a first connecting channel 5 is arranged on one side of the stirring mechanism 4, and a connecting channel 5 is arranged on the other end of the first connecting channel 5 and fixed on the top of the box body 1. Feed screening mechanism 6, one side of the feed screening mechanism 6 is provided with a discharge pipe 8, the feed screening mechanism 6 is connected with a second connecting channel 7, and the other end of the second connecting channel 7 is installed on the stirring mechanism 4 superior.

Embodiment 2

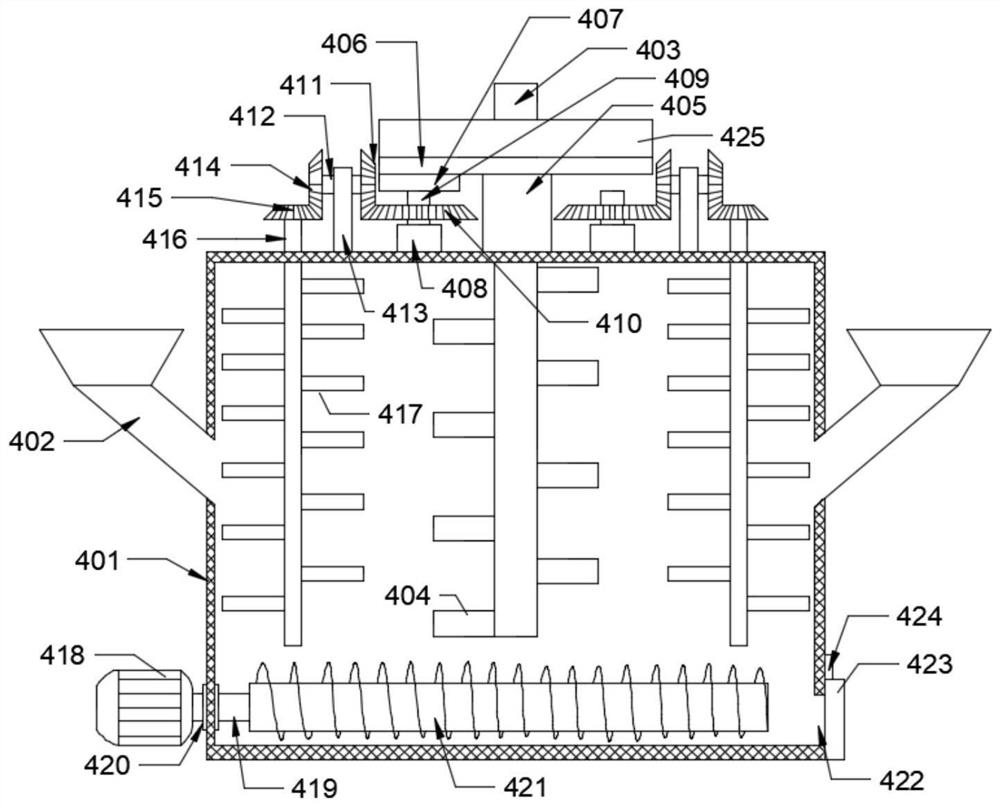

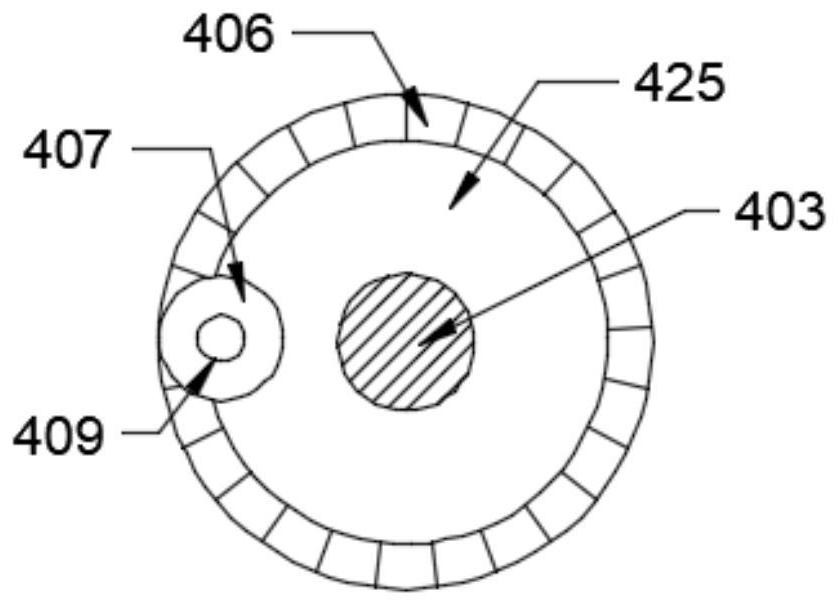

[0032] see Figure 1-8 , in this embodiment, the stirring mechanism 4 includes: a stirring tank body 401, a feed port 402 is installed on the side tank body of the stirring tank body 1, and a first stirring rod 403 runs through the middle of the stirring tank body 401 The first stirring rod 403 is provided with a first stirring blade 404 on the rod body inside the stirring tank body 401, the upper part of the first stirring rod 403 is fixed with a disc 425, and the lower part of the disc 425 is fixed with a first tooth Ring 406, a first motor 408 is fixed on the mixing tank body 401 at the bottom of the first gear ring 406, a first rotating shaft 409 is installed on the first motor 408, and a second rotating shaft 409 is fixed on the bottom of the first rotating shaft 409. Two gear rings 407, the second gear ring 407 meshes with the first gear ring 406, a first bevel gear 410 is installed in the middle of the first rotating shaft 409, and a second bevel gear is meshed on one s...

Embodiment 3

[0038] see Figure 1-8 , in this embodiment, the feed screening mechanism 6 includes: a base 601, a first rotating base 602 is fixed on the upper side of the base 601, and a second rotating base 603 is rotatably connected to the first rotating base 602 , the second rotating base 603 is fixedly connected with a long block 604, and the long block 604 is provided with a groove 605, and a first sliding column 606 is arranged in the groove 605, and the first sliding column The top of 606 is fixedly connected with a collection box 607, a crank 608 is arranged on one side of the first sliding column 606, and the other end of the crank 608 is rotatably connected with a connecting rod 609, and the other end of the connecting rod 609 is rotatably connected with a second sliding rod 609. Column 611, the top of the second sliding column 611 is fixedly connected with a sieve plate 612, the sieve plate 612 is provided with a sieve hole 615 with the same aperture, a conveyor belt 614 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com