Waste gas treatment equipment

A technology for waste gas treatment equipment and waste water, which is applied in the separation of dispersed particles, chemical instruments and methods, and the use of liquid separation agents, etc., can solve problems such as a large number of harmful waste water, and achieve the effect of reducing costs and reducing waste water generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment without creative contribution as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

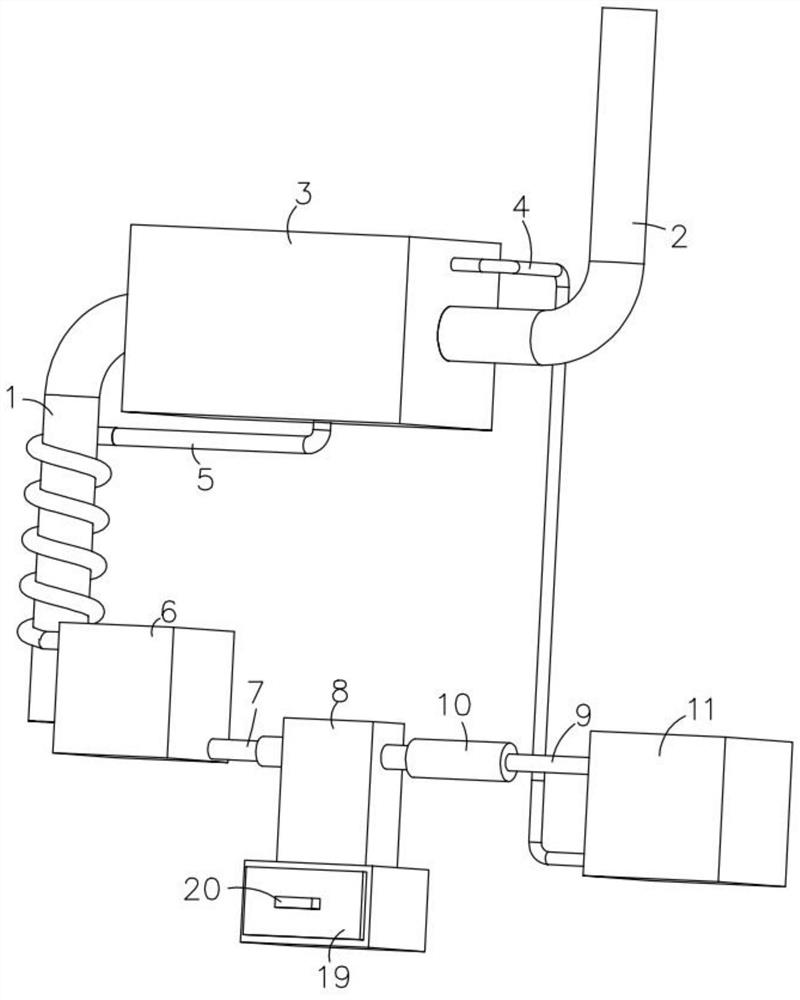

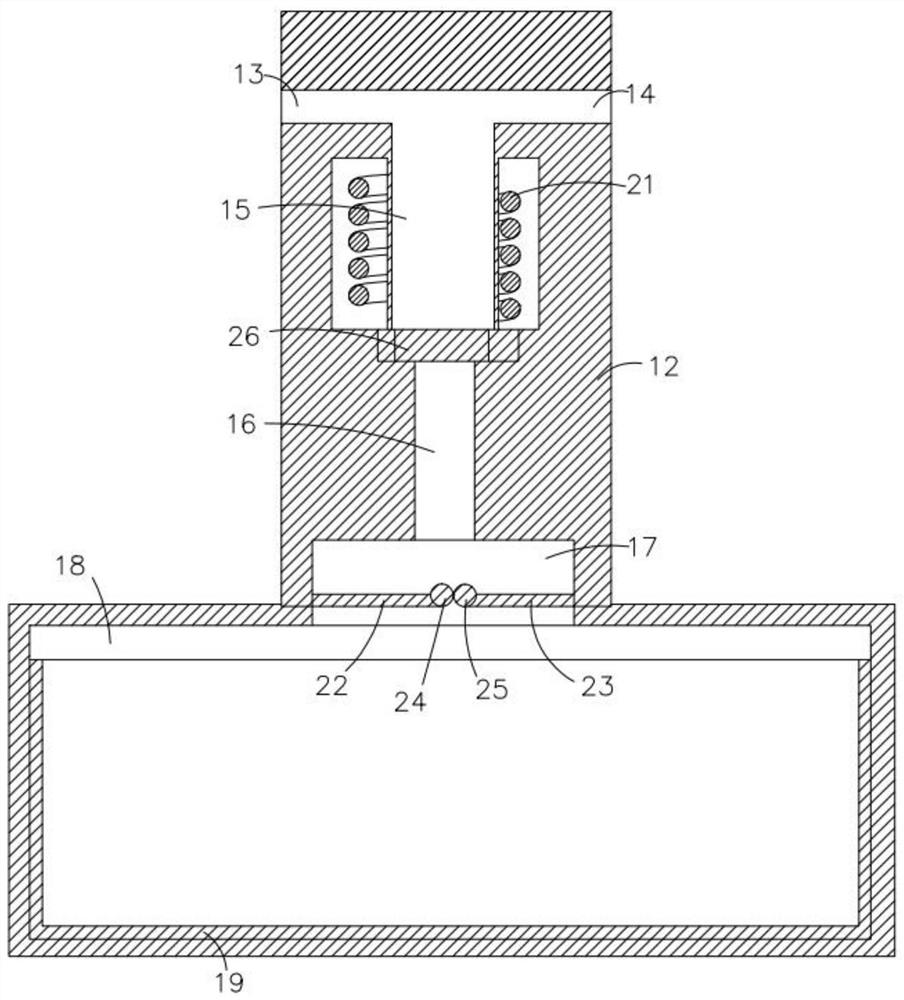

[0022] Such as figure 1 and figure 2 As shown, a kind of waste gas treatment equipment includes an air inlet pipe 1, an air outlet pipe 2, a spray chamber 3, a spray pipe 4, a waste water collection pipe 5, a waste water temporary storage tank 6, a first delivery pipe 7, a dryer 8, The second conveying pipe 9, the condenser 10, the water pump and the water storage tank 11, the dryer 8 includes a main body 12, an electric heating coil 21, a first discharge plate 22, a second dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com