Peach gum extract as well as preparation method and application thereof

A technology of extract and peach gum, which is applied in the field of peach gum extract and its preparation, can solve the problems that the safety of surfactants cannot be guaranteed at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0124] Embodiment 1, anti-surfactant stimulates raw material screening

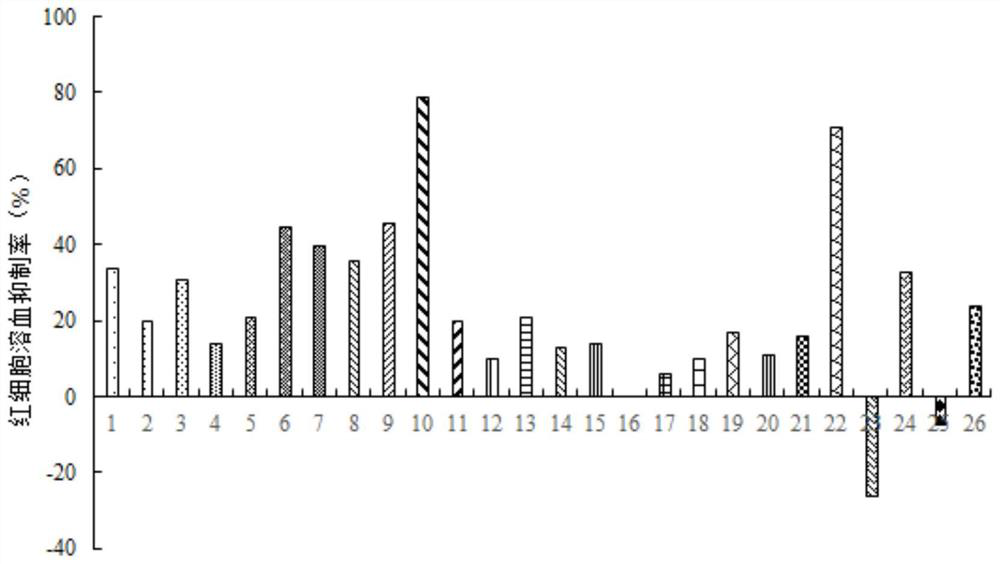

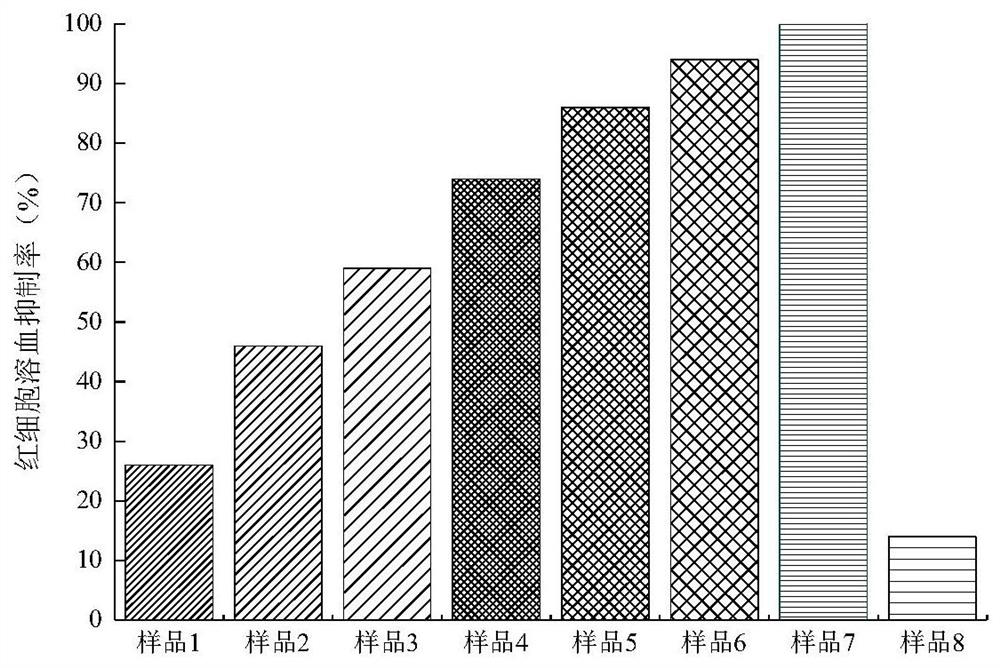

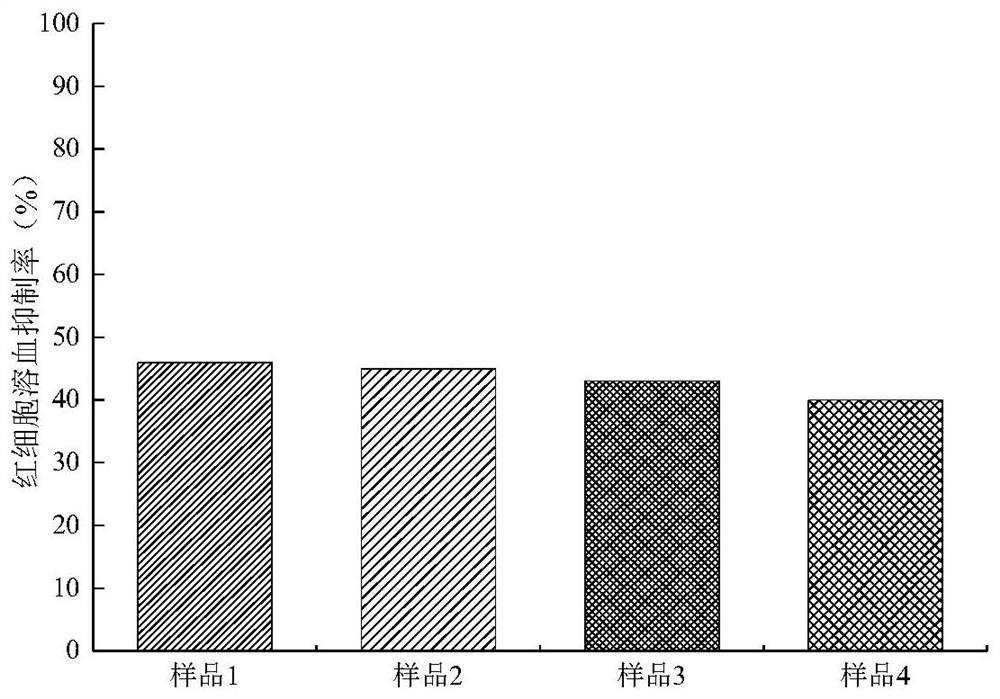

[0125] The present invention screens a variety of Chinese medicine raw materials and compounds that claim to have anti-stimulation and extracts them, and through the red blood cell hemolysis and coagulation test, investigates the antagonistic effect of each Chinese medicine extract on the red blood cell stimulation caused by SDS.

[0126] The present invention also investigated the antagonistic effect of different polysaccharides and three competing products on the red blood cell stimulation caused by SDS.

[0127] Table 1 Sources of raw materials used

[0128]

[0129]

[0130] Market Competitor 1 Ingredients: Butylene Glycol, Water, Centella Asiatica (Centella Asiatica) Extract, Polygonum Cuspidatum Root Extract, Scutellaria Baicalensis Root Extract, Tea (Camellia Sinensis) Leaf Extract, Light Glycyrrhiza Glabra Root Extract, Chamomilla Recutita Flower Extract, Rosemary (Rosmarinus Officinalis) L...

Embodiment 2

[0167] Preparation process:

[0168] According to peach gum: water = 1:20 (m / m), extract with pure water, extract at 70°C for 1.5h; centrifuge at 5000rpm / min for 10min, take the supernatant; use a 50nm microfiltration membrane module for microfiltration and concentration, remove For substances with a molecular weight below 50wDa in the supernatant, retain the effluent to obtain a microfiltrate; add the microfiltrate and 95% ethanol at a ratio of 1: 10 (m / v), stir evenly, and after standing at room temperature for 12 hours, take out the precipitated substance; Freeze-dry at -80°C for 10 hours; pulverize; sterilize at 120°C for 1 hour to obtain peach gum macromolecular polysaccharide extract.

Embodiment 3

[0170] Preparation process:

[0171] According to peach gum: water = 1:10, extract with pure water, extract at 80°C for 0.5h, centrifuge at 4000-8000rpm for 25min, and take the supernatant; use a 50nm microfiltration membrane module to perform microfiltration and concentration, and remove the molecular weight in the supernatant For substances below 50wDa, keep the effluent to obtain the microfiltrate; add the microfiltrate and 95% ethanol at a ratio of 1:5 (m / v), stir evenly, and after standing at room temperature for 10h, take out the precipitated substance and freeze at -50°C Dry for 32 hours, pulverize, and sterilize at 140°C for 0.5 hours to obtain peach gum macromolecular polysaccharide extract.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com