Energy-saving irrigation device for hydraulic engineering

A technology for water conservancy projects and irrigation devices, which is applied in watering devices, fertilizing devices, and devices for capturing or killing insects, etc., can solve problems such as increased cost, large flow, and inability to spray pesticides or fertilizers, so as to improve the utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

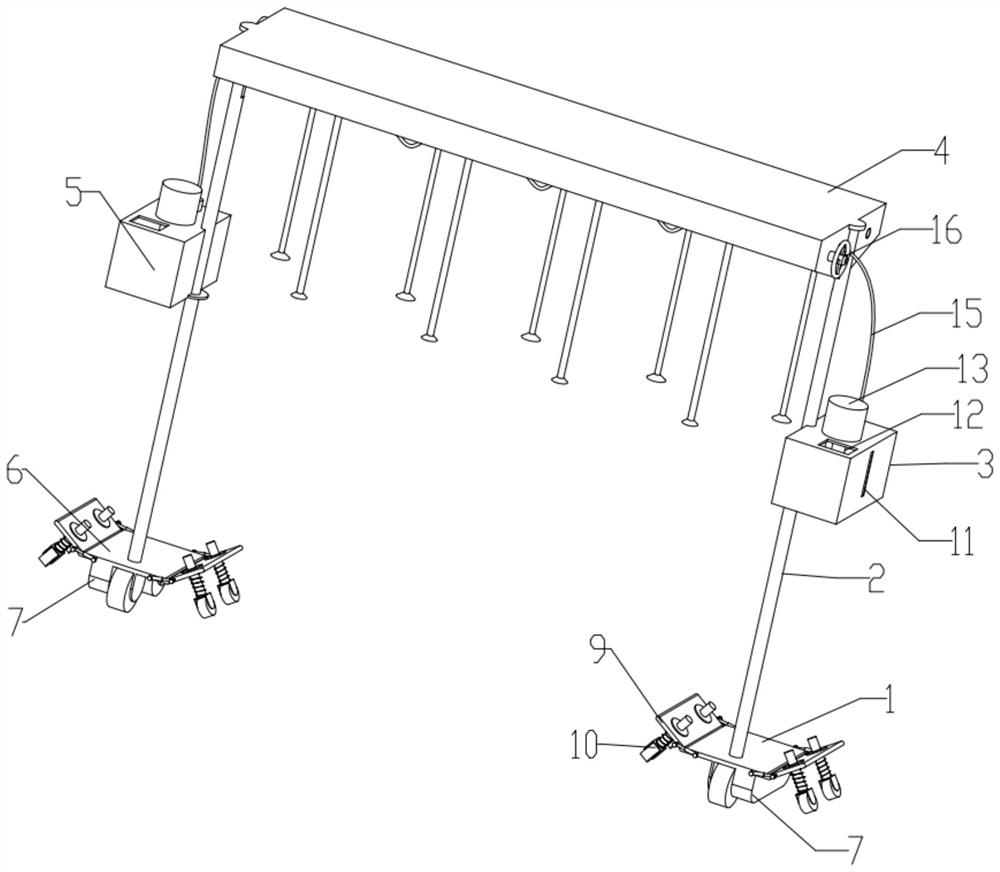

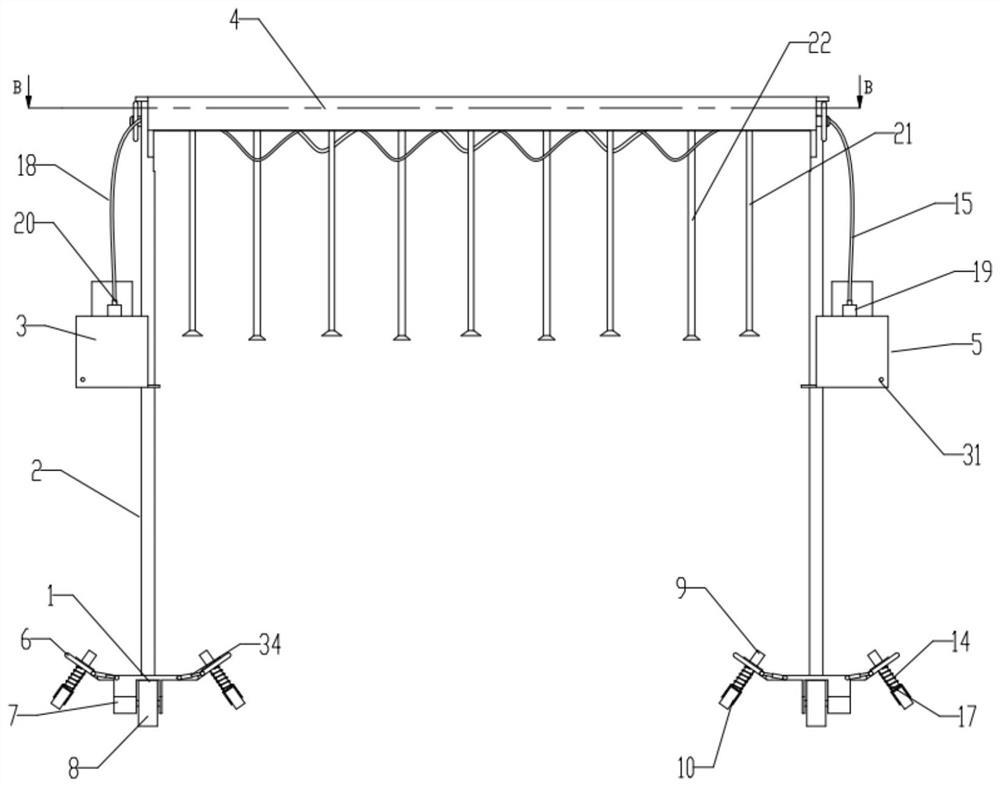

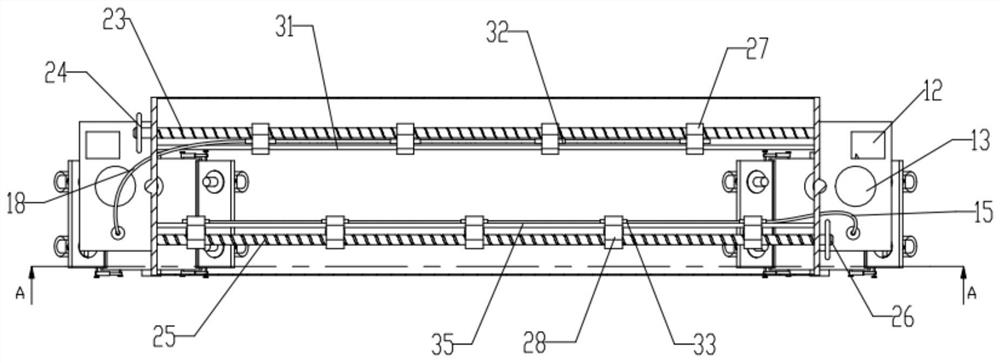

[0033] An energy-saving irrigation device for water conservancy projects, comprising a mobile base 1, a first water outlet tank 3, a second water tank 5, and a workbench 4. The upper part of the mobile base 1 is provided with a support rod 2, and the bottom of the support rod 2 is in contact with the mobile The base 1 is fixed, and the top of the support rod 2 is fixed to the workbench 4. The inside of the workbench 4 is provided with a first screw screw 23 and a second screw screw 25, the first screw screw 23 and the second screw screw Bar 25 is all rotatably connected with the side wall of workbench 4 by bearing, and the circumferential direction of the first screw screw 23 is provided with the first slide block 27, and the first screw screw 23 runs through the first slide block 27, and the first slide block 27 Internally provided with an internal thread that cooperates with the external thread of the first screw screw 23, the circumferential direction of the second screw scr...

Embodiment 2

[0035] The outer sides of the first water outlet tank 3 and the second water tank 5 are equipped with a liquid level gauge 11, the liquid level gauge 11 is made of transparent glass, and the first water outlet tank 3 and the second water outlet tank 3 can be detected by the liquid level gauge 11. The liquid storage situation of the two water tanks 5, in addition, when spraying pesticides or carrying out foliar fertilization, the liquid level gauge 11 can be used to proportion a certain amount of pesticides or fertilizers, the first water outlet tank 3 and the second water tank The casing upper side of 5 is provided with water inlet 12, and stirring motor 13, and the power output end of stirring motor 13 is provided with stirring blade, and stirring blade stretches into the bottom of the first water outlet tank 3 and the second water tank 5, so The top of the first water outlet box 3 is provided with a first water outlet pipe 15, the first water outlet pipe 15 runs through the s...

Embodiment 3

[0037] The first sliders 27 are arranged at equal intervals along the axis direction of the first screw screw 23, and the second sliders 28 are arranged at equal intervals along the axis direction of the second screw screw 25. A slide block 27 is located between the two second slide blocks 28, the first slide block 27 is provided with a first guide rod 31 on the side away from the first screw screw 23, and the two ends of the first guide rod 31 are fixed on On the inner wall of the workbench 4, the first guide rod 31 runs through the first slide block 27, the first slide block 27 is provided with a first three-way valve 32, and the second slide block 28 is far away from the second screw screw 25. One side is provided with second guide rod 35, and the two ends of second guide rod 35 are fixed on the inner wall of workbench 4, and second guide rod 35 runs through first slide block 27, and first slide block 27 is provided with second three. Through the valve 33, the left side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com