Rotor core, motor rotor, motor

A rotor core and iron core technology, which is applied in the field of motors, rotor cores, and motor rotors, can solve problems such as magnetic flux leakage and large torque ripple, and achieve the effects of eliminating harmonics, reducing torque ripple and cogging torque Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

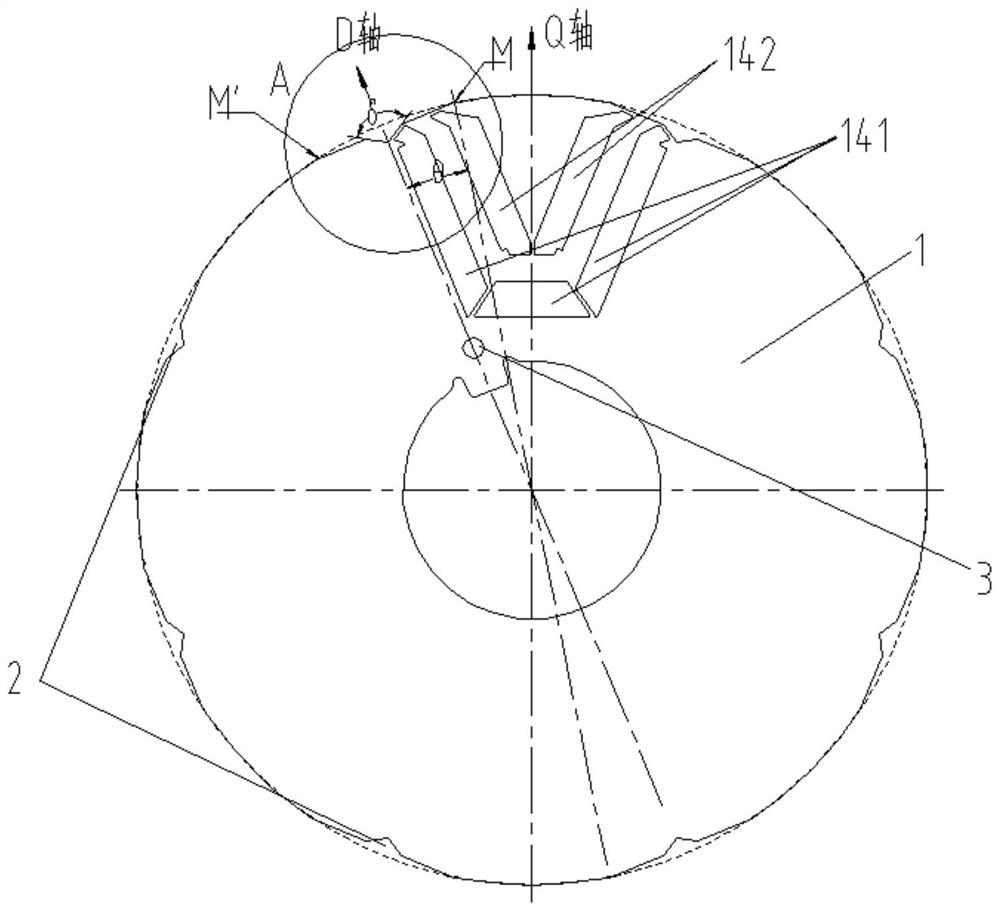

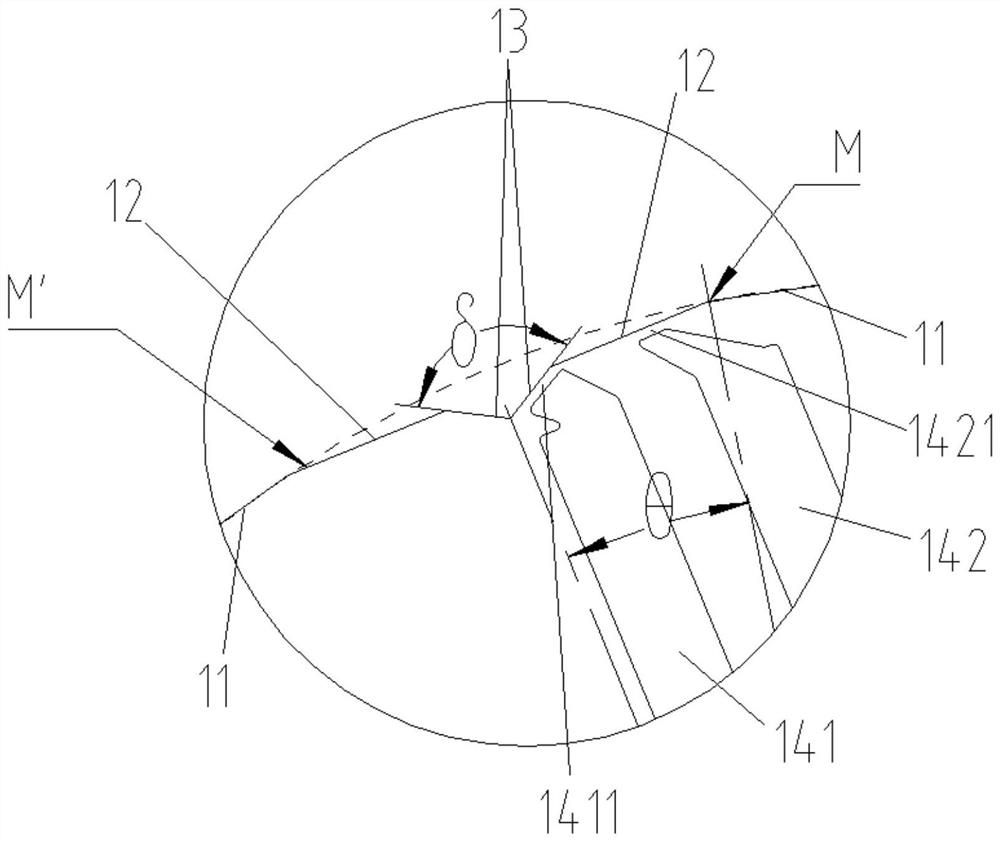

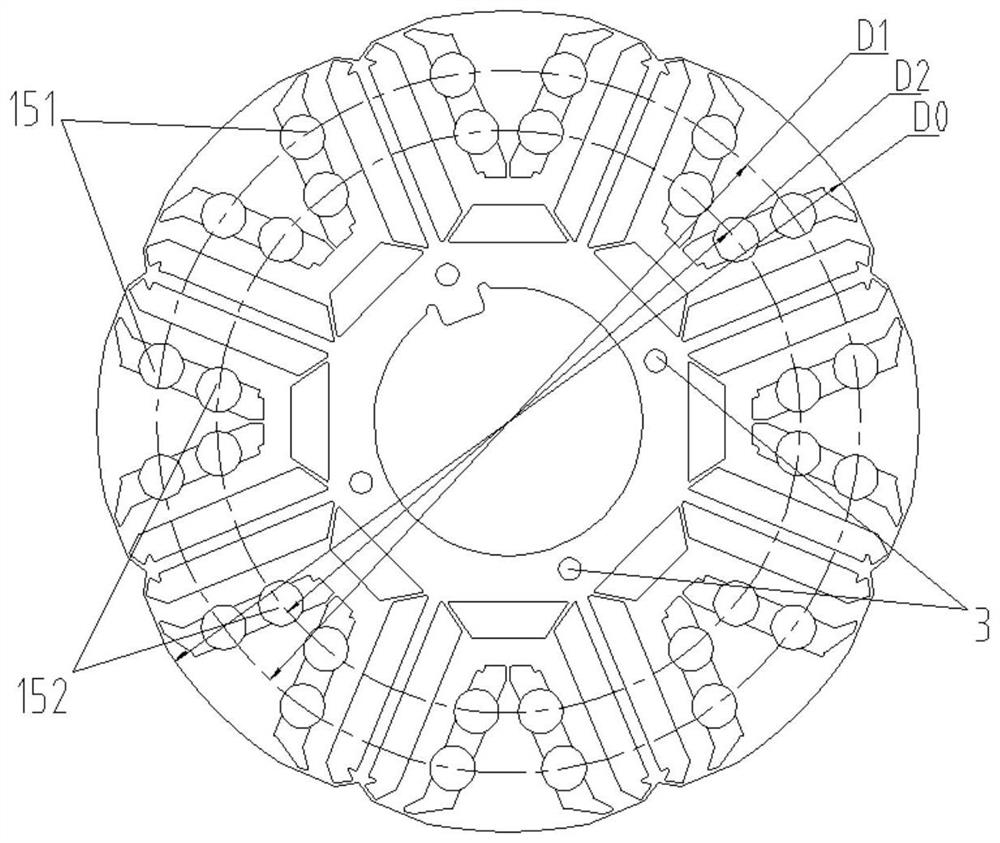

[0031] see in conjunction Figure 1 to Figure 8 As shown, according to the embodiment of the present invention, a rotor core is provided, which includes a core body 1, the core body 1 has a plurality of magnetic poles that alternate evenly along its circumferential direction, and any two adjacent magnetic poles are about D Axisymmetric, on any radial surface of the iron core body 1, in the same magnetic pole, the outer peripheral wall of the iron core body 1 has a circular arc symmetrical about the Q axis (the axis of symmetry of each magnetic pole) segment 11 and the trimming straight segment 12 at both ends of the arc segment 11, the length of the line between any point on the trimming straight segment 12 and the axis of the iron core body 1 is shorter than the arc The length of the line between any point on the segment 11 and the axis of the iron core body 1 . In this technical solution, by replacing the outer circular arc of the rotor iron core with a straight line trimmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com