Small guide pipe grouting construction method for treating water gushing of inclined shaft of tunnel

A small conduit and grouting technology, which is applied in tunnels, tunnel linings, shaft linings, etc., can solve problems affecting construction progress, hollowing out of tunnel surrounding rock, piping disasters, etc., achieve good economic and social benefits, prevent mud and sand, Ensure the stability of the surrounding rock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following clearly and completely describes the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

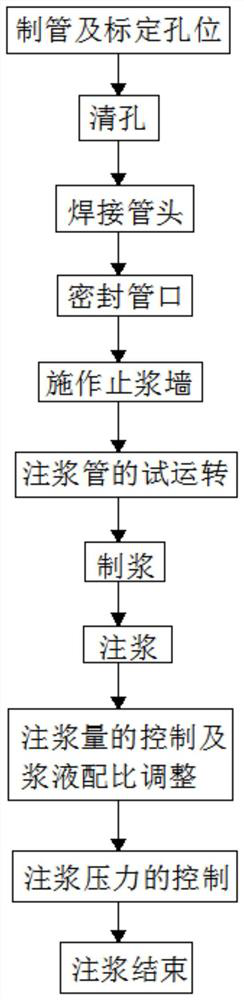

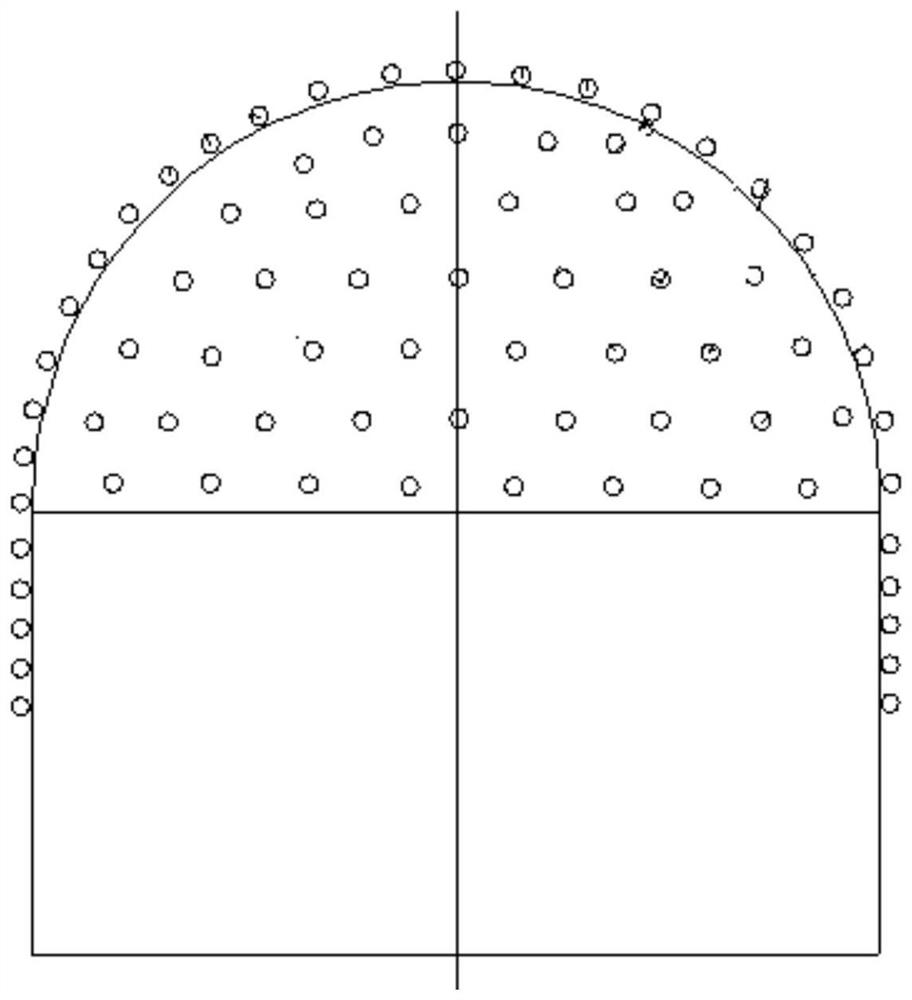

[0041] Such as figure 1 , figure 2 As shown, a small conduit grouting method for controlling water gushing in inclined shafts of tunnels includes the following steps:

[0042] S1, pipe making and calibration hole position;

[0043] S2, clear hole;

[0044] S3. Welding pipe head: welded on the grouting pipe with a short sleeve wire pipe;

[0045] S4, sealing nozzle;

[0046] S5, apply the grout stop wall;

[0047] S6, trial operation of the grouting pipe;

[0048] S7. Pulping: The laboratory will test different water-cement r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com