A fastening structure and method for a prefabricated building formwork

A technology for building templates and fastening structures, which is applied in building construction, on-site preparation of building components, construction, etc. It can solve problems such as difficulty in ensuring verticality of walls, troublesome end handling, cumbersome operations, etc., and achieves installation and reinforcement Convenient and fast, high reuse rate, high quality assurance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

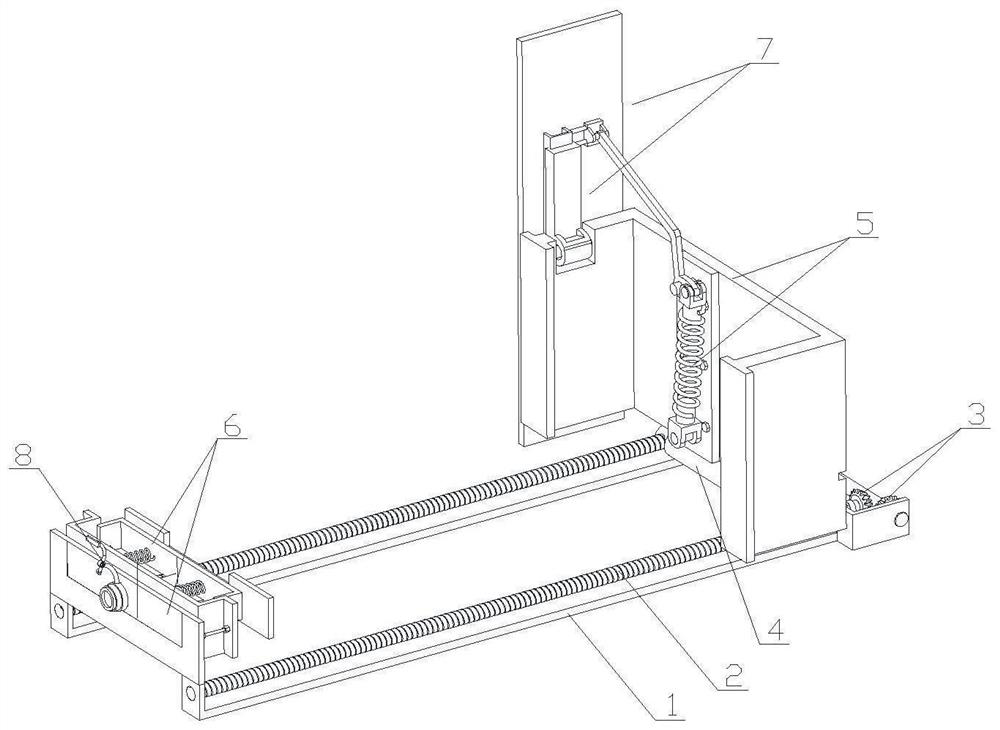

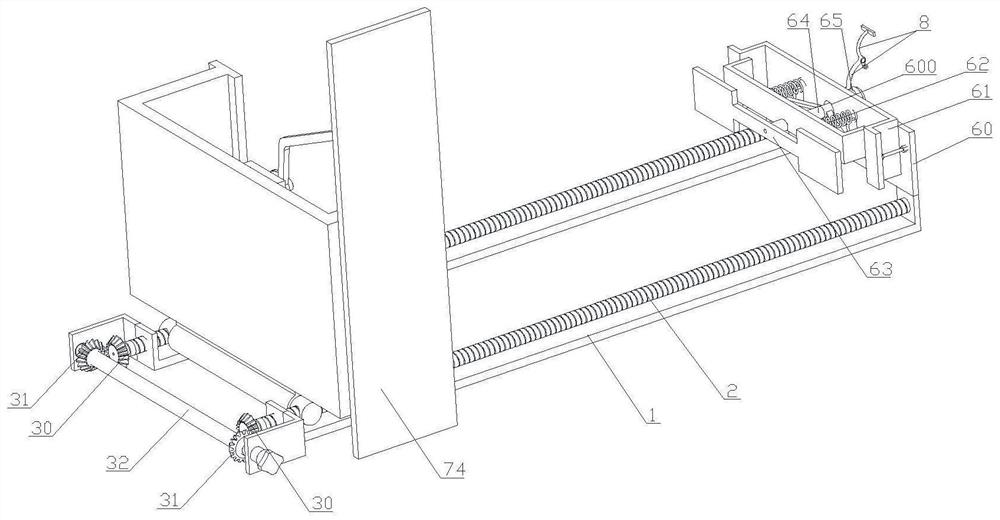

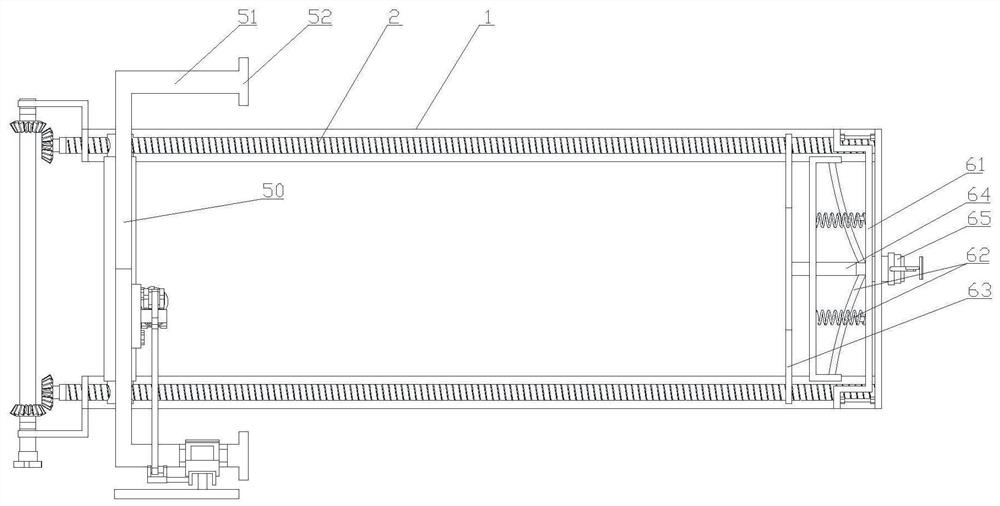

[0046] see Figure 1 to Figure 8 The technical solution provided by the present invention is that a prefabricated building formwork fastening structure comprises two guide seats 1 arranged oppositely, two drive screws 2 respectively arranged on the two guide seats 1, and one end of the two drive screws 2 is provided with a drive The rotating gear drive assembly 3 is provided with a reciprocating moving assembly 4 that reciprocates along the two driving screws 2 between the two driving screws 2. There is also an elastic clamping assembly 6 opposite to the moving clamping member 5 therebetween.

[0047] Specifically, the movable clamping member 5 includes a carrier plate 50, and two lateral limit plates 51 are respectively provided on both sides of the carrier plate 50. Each side limit plate 51 is provided with a lateral clip plate 52, which is mounted on the carrier plate 50. The inner side of the plate 50 is provided with an elastic return mechanism 53 , and between the elast...

Embodiment 2

[0067] On the basis of Embodiment 1, the elastic clamping component 6 can also be other elastic clamping components that move along the axis of the drive screw 2, so as to realize the reinforcement and fine adjustment of the positioning of the formwork on both sides of the wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com