Rapid dredging device

A dredging device and fast technology, applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., which can solve the problem of reduced water treatment capacity, low efficiency of sewage suction pump, and incompatibility with mine continuity. production and other issues to achieve the effect of increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object and technical solutions of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and embodiments:

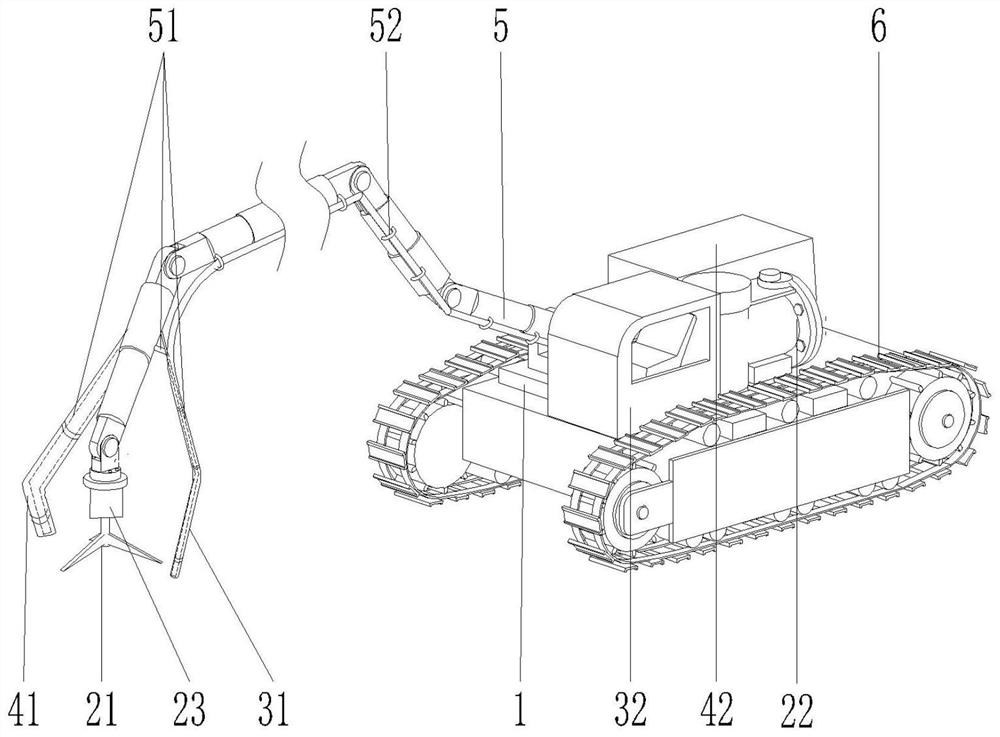

[0017] Such as figure 1 A kind of rapid dredging device shown, comprises: base 1, is provided with stirring device, air injection device, sewage suction device; Said stirring device is connected with stirring blade 21; Said air injection device is connected with high-pressure pipeline 31; The sewage suction device is connected with a sewage suction pipeline 41; the mechanical arm 5 is installed and fixed on the base 1; the front end of the mechanical arm 5 is fixedly connected to the stirring blade 21, the high-pressure pipeline 31 and the sewage suction pipeline 41 ; The control device (not shown in the figure) controls the work of the mechanical arm 5, the stirring device, the air injection device and the sewage suction device.

[0018] Preferably, a mounting frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com