Advanced treatment and recycling equipment for high-concentration organic sewage

A technology for advanced treatment of organic sewage, applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as blockage of purification and treatment settings, time-consuming and labor-intensive equipment, etc., to prevent The effect of clogging and long-term use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

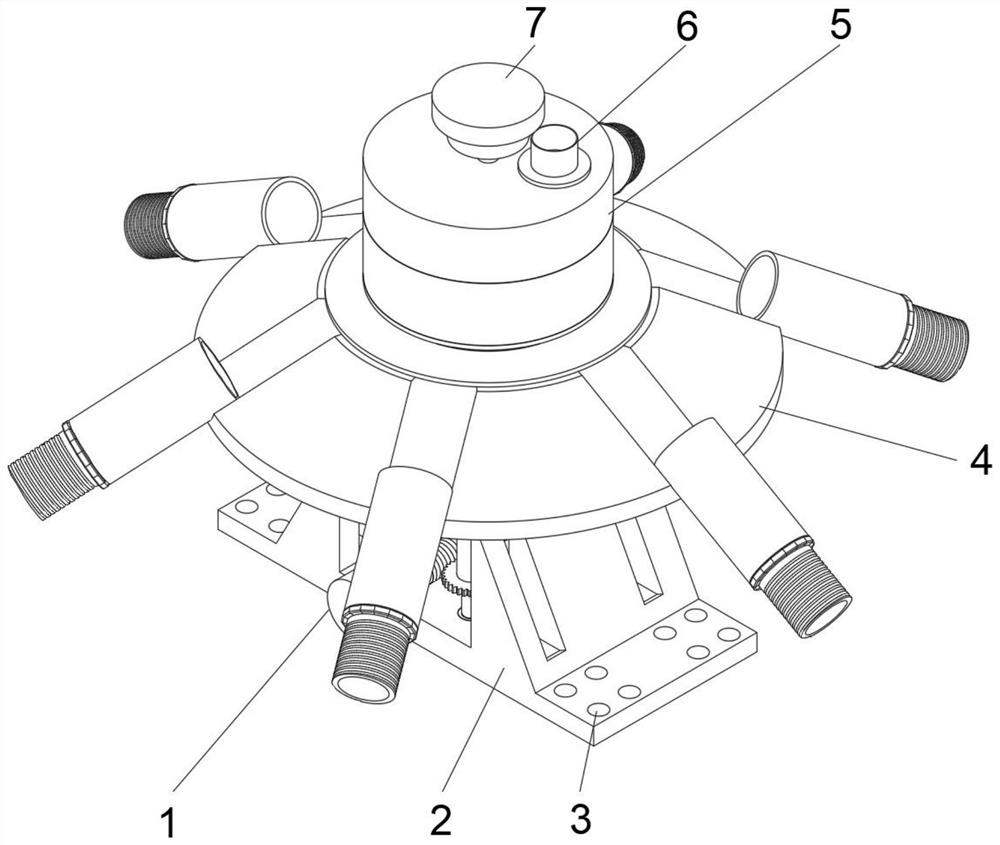

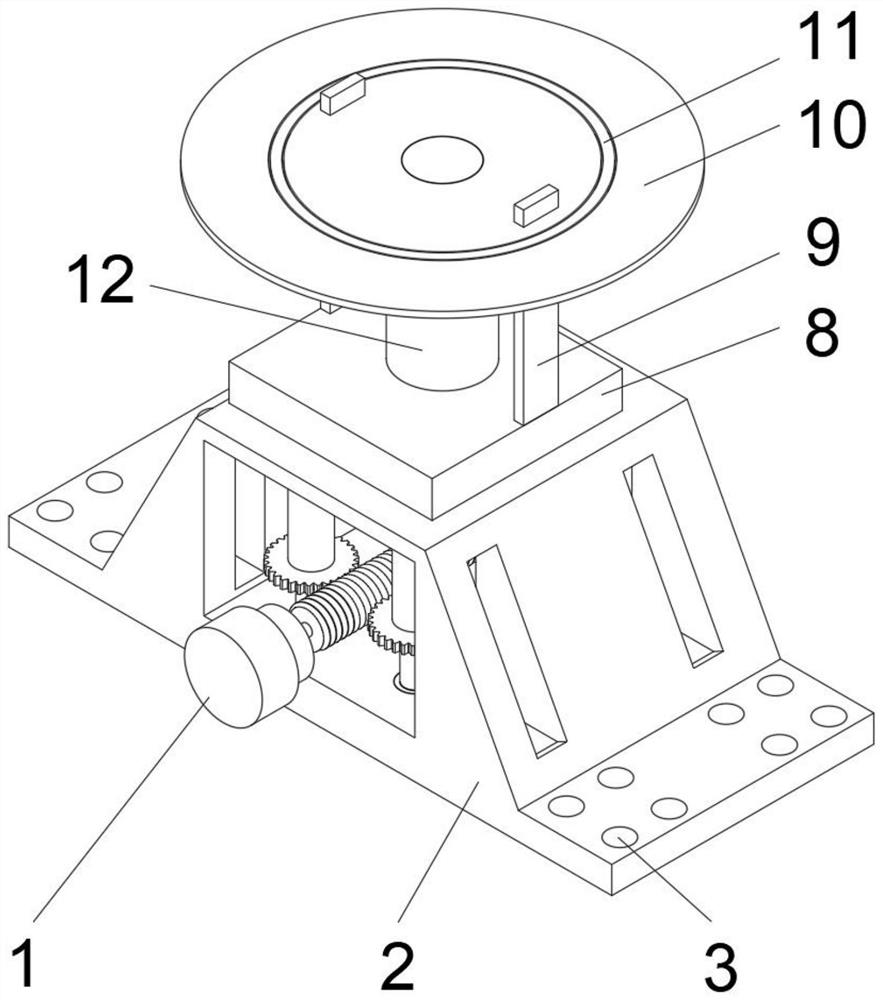

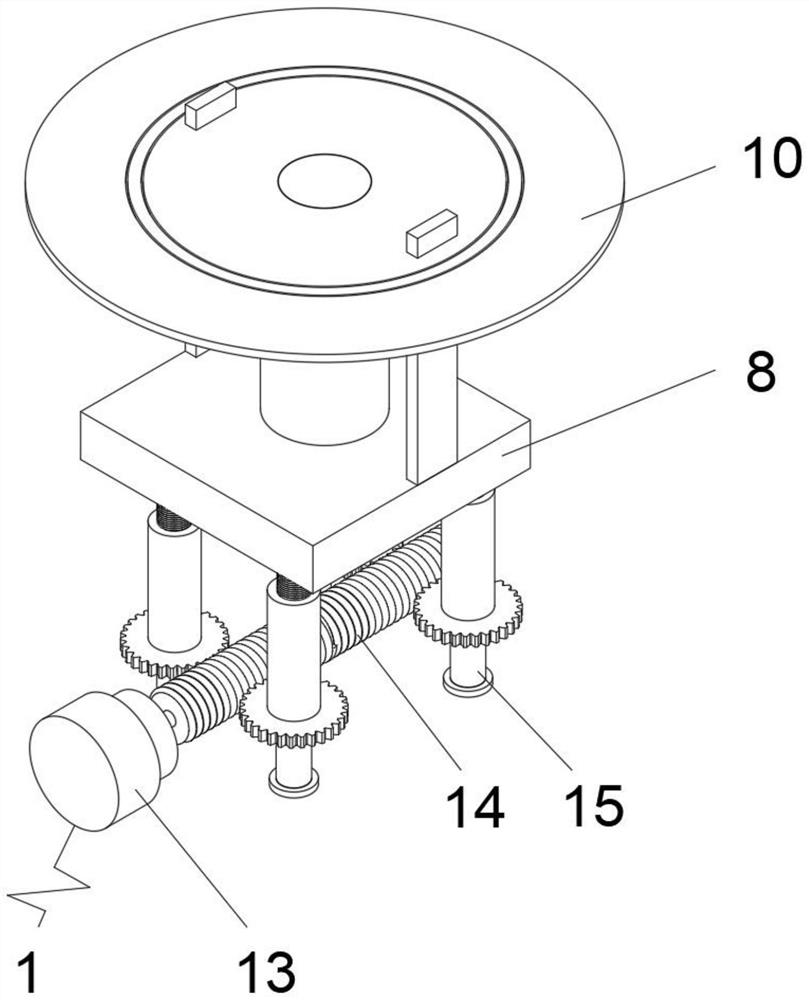

[0036] see figure 1 , an embodiment provided by the present invention: an advanced treatment and reuse equipment for high-concentration organic sewage, including a drive adjustment device 1, a support bracket 2, a fixed installation hole 3, a discharge device 4, a stirring device 5, and a water inlet pipe 6 and break the motor 7, the fixed installation holes 3 are opened at the two ends of the supporting fixed frame 2, the driving adjustment device 1 is installed in the middle of the supporting fixed frame 2, the discharge device 4 is fixedly installed above the supporting fixed frame 2, and the stirring device 5 is fixed Installed in the upper middle part of the discharge device 4, the crushing motor 7 is fixedly installed in the upper middle part of the stirring device 5, the water inlet pipe 6 is fixedly installed in the upper end of the stirring device 5, and the water inlet pipe 6 is positioned at the side of the crushing motor 7, will need The treated waste water is disc...

Embodiment 2

[0046] On the basis of Example 1, such as Figure 9 As shown, a filter screen 36 is fixedly installed on the outer end of the fixing ring 32, and the material of the filter screen 36 is stainless steel.

[0047] When implementing this embodiment, a filter screen 36 is installed at the end of the fixed ring 32 in the blocking device 22, which can filter the sewage entering the connecting pipe 21 again to prevent the inside of the connecting pipe 21 from being blocked, and The filter screen 36 is made of stainless steel, which has a long service life, and the larger debris intercepted by the filter screen 36 is convenient for cleaning.

[0048] Working principle: First, the waste water to be treated is discharged from the water inlet pipe 6 to the inside of the first grinding frame 28 and the second grinding frame 31, and then the crushing motor 7 is started, and the grinding disc 25 is driven by the crushing motor 7 to rotate. A grinding disc 25 is installed inside the first g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com