Energy-saving and environment-friendly ring-pull can extruding and recycling device

A recovery device, energy-saving and environment-friendly technology, which is applied in the direction of stamping machines, presses, manufacturing tools, etc., can solve the problems of cans being easily stuck in the equipment, unable to unload cans, and blockage of extrusion channels, etc., to achieve uniform feeding and work High efficiency and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

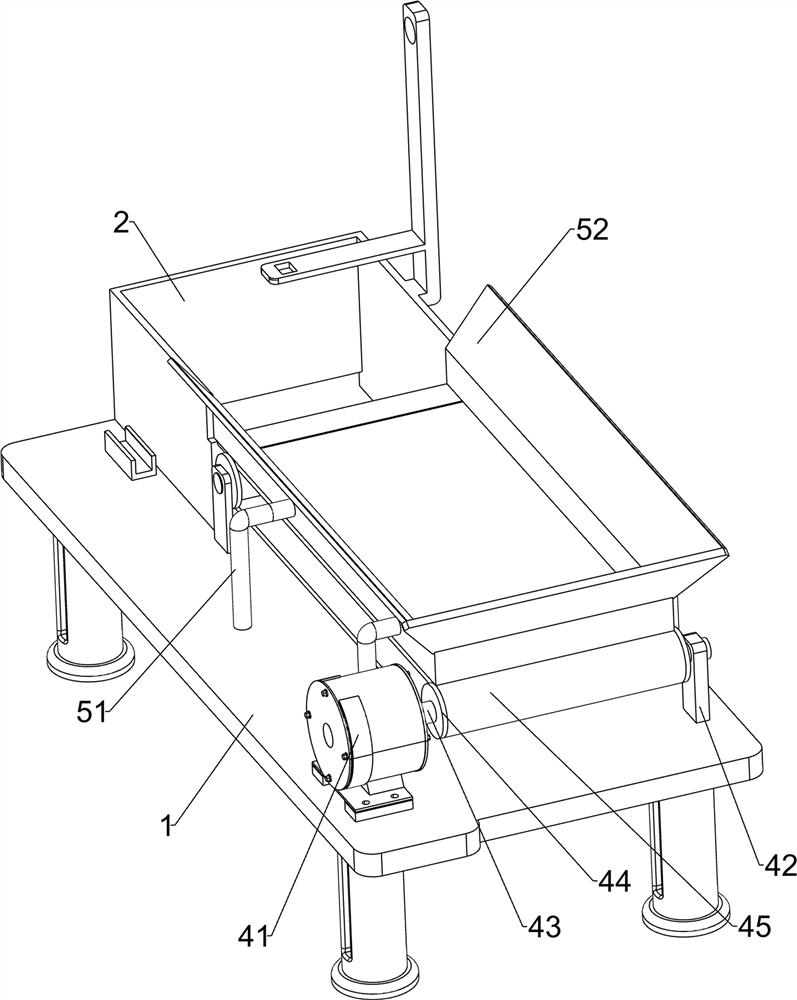

[0028] A kind of energy-saving and environment-friendly pop can extrusion recovery device, such as Figure 1-3 As shown, it includes a base 1, a pressure groove 2, a fixed frame 3, a driving mechanism 4, a stopper assembly 5, a placement assembly 6 and an extrusion assembly 7. The left side of the base 1 is connected with the pressure groove 2, and the top right of the base 1 The side is connected with a fixed frame 3, and the right side of the base 1 is equipped with a drive mechanism 4 and a stopper assembly 5, the stopper assembly 5 is located above the drive mechanism 4, the bottom of the press groove 2 is connected with a placement assembly 6, and the upper part of the press groove 2 is provided with There are extrusion components 7 .

[0029] The driving mechanism 4 includes a motor 41, a fixed plate 42, a first shaft rod 43, a transmission roller 44 and a conveyor belt 45. The motor 41 is installed on the right front side of the base 1, and two fixed plates are connecte...

Embodiment 2

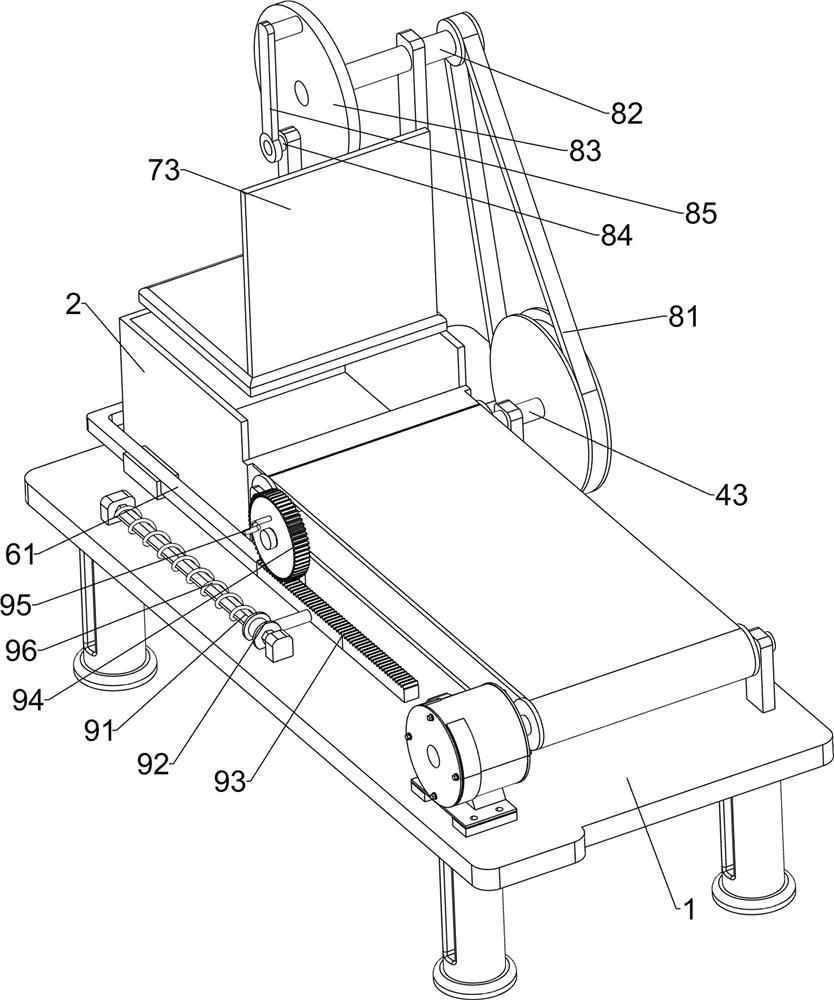

[0035] On the basis of Example 1, such as Figure 4 As shown, a transmission mechanism 8 is also included, and the transmission mechanism 8 includes a belt assembly 81, a second shaft 82, a turntable 83, a third shaft 84 and a connecting rod 85, and the top of the pressure groove 2 is rotatably connected with a second The shaft 82, the belt assembly 81 is connected between the rear end of the first shaft 43 on the left side and the rear end of the second shaft 82, the front end of the second shaft 82 is connected with a turntable 83, and the top of the extrusion rod 71 rotates A third shaft 84 is rotatably connected to the eccentric portion of the third shaft 84 and the turntable 83 , and a connecting rod 85 is rotatably connected.

[0036] When the first shaft 43 on the left side rotates, the belt assembly 81 drives the second shaft 82 to rotate, the second shaft 82 rotates to drive the turntable 83 to rotate, and the turntable 83 rotates to drive extrusion through the third ...

Embodiment 3

[0040] On the basis of Example 2, such as Figure 5 As shown, a blanking mechanism 10 is also included, and the blanking mechanism 10 includes a blanking box 101, an L-shaped connecting rod 102, a first material separating plate 103, a second material separating plate 104, and a second inner edge type guide sleeve 105 , guide rail 106 and cylinder 107, the top of fixed frame 3 is connected with blanking box 101, the bottom of blanking box 101 is connected with the first material partition 103 slidingly, the front end bottom of the first material partition 103 is connected with L-shaped Connecting rod 102, the tail end of L-shaped connecting rod 102 is connected with second material partition 104, and the second material partition 104 contacts and cooperates with the bottom of cutting box 101, and the middle part of fixed frame 3 is connected with guide rail 106, and on guide rail 106 Slidingly connected with the second inner edge type guide sleeve 105, the second inner edge ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com