Rapid waste recovery processing device for optical fiber cable sheath

A technology for recycling and processing cables, which is applied in the field of rapid recycling and processing devices for waste materials used in optical fiber and cable sheaths. It can solve the problems of poor mixing effect, affecting the melting time of insulating layers, and easy adhesion of heating tanks, etc., so as to improve efficiency. , avoid internal accumulation, improve the effect of melting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

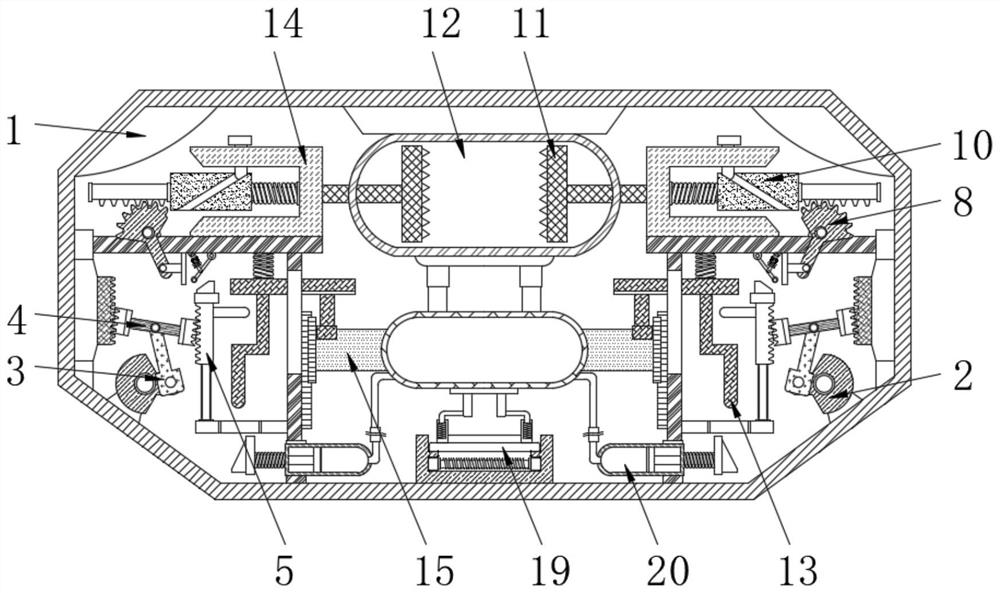

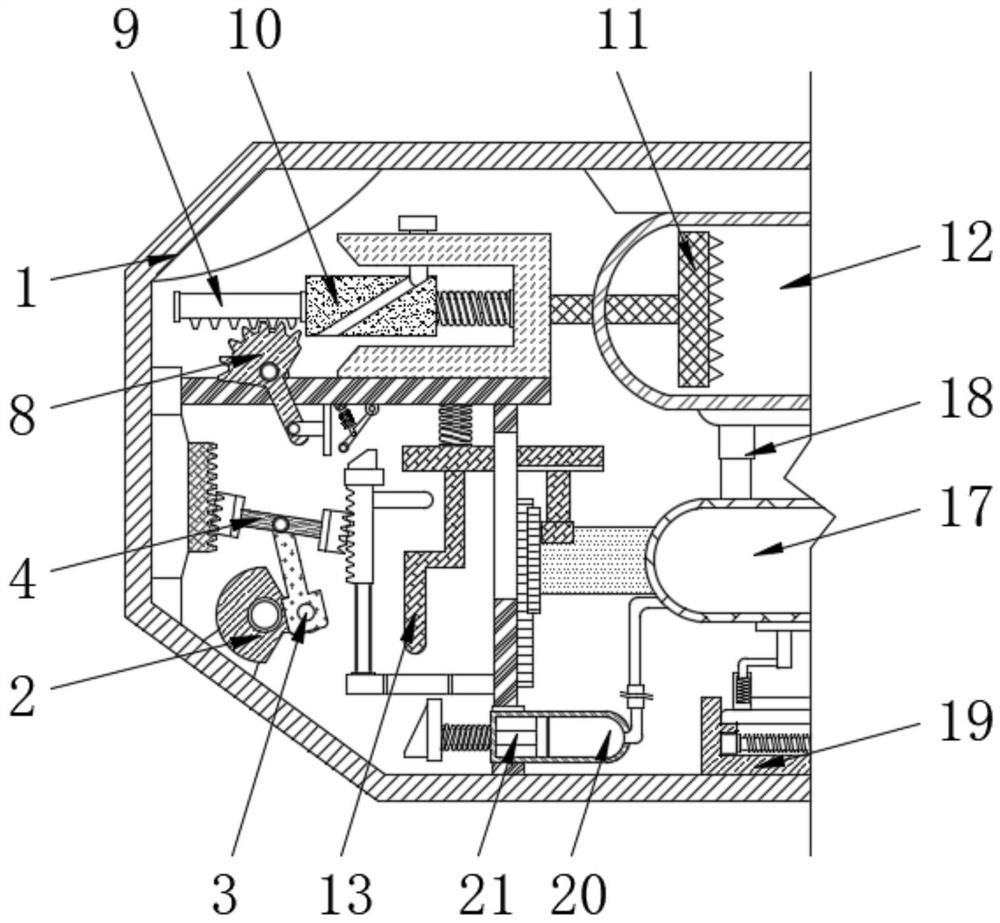

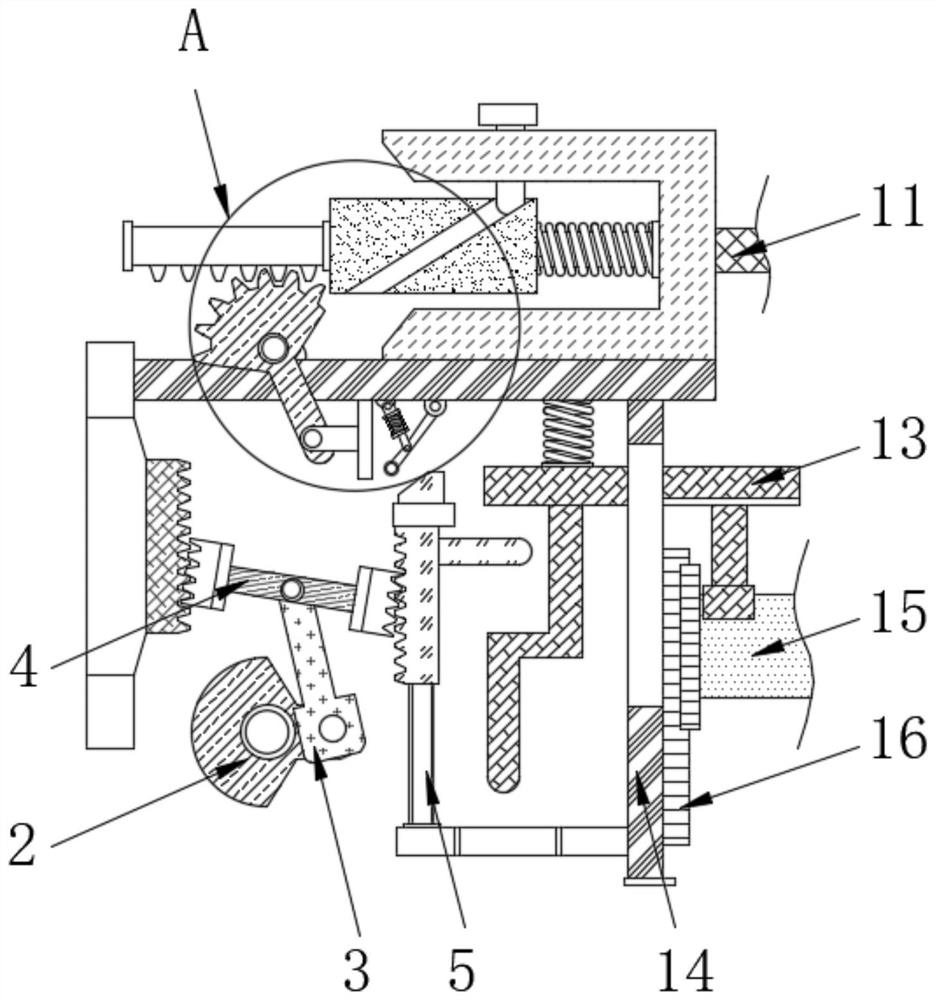

[0019] The present invention will be further described below in conjunction with accompanying drawing:

[0020] The invention provides a device for quick recovery and treatment of waste materials for the outer sheath of optical fiber cables, as attached figure 1 to attach Figure 4 Shown: including the processing chamber 1, the inner rotation of the processing chamber 1 is equipped with a fan-shaped plate 2, the fan-shaped plate 2 is fixedly connected with the drive shaft, the front surface of the fan-shaped plate 2 is movable and installed with a rotating rod 3, and the top of the rotating rod 3 is movable Connected to the center of the swing frame 4, the inner end of the swing frame 4 is engaged with a telescopic rod 5, the inner wall of the processing chamber 1 is provided with a tooth plate corresponding to the swing frame 4, and an elastic frame 6 is provided above the telescopic rod 5, fan-shaped When the plate 2 rotates, it drives the rotating rod 3 to rotate. Using th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com