Auxiliary supporting vibration suppression device for milling thin-wall curved-surface part

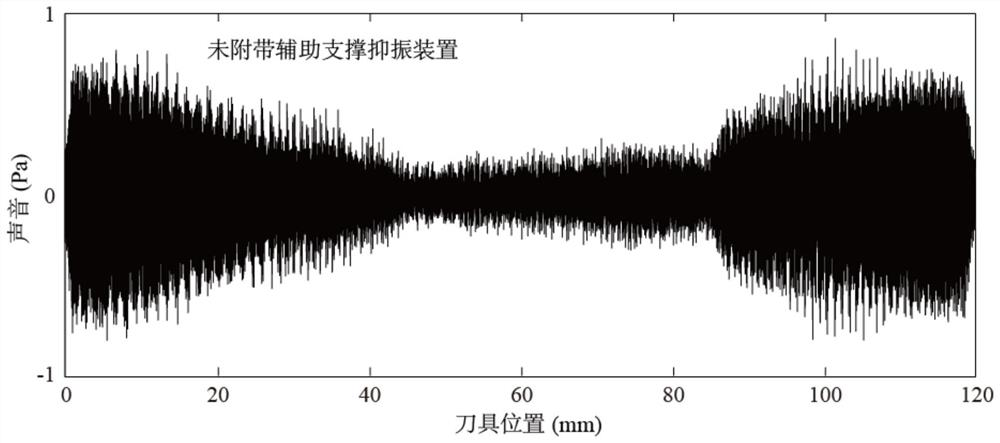

A technology of curved surface parts and auxiliary support, which is applied in the direction of positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problem of easy chatter of curved surface thin-walled parts, achieve uniform force, reduce sound signal, and not easy to deform Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

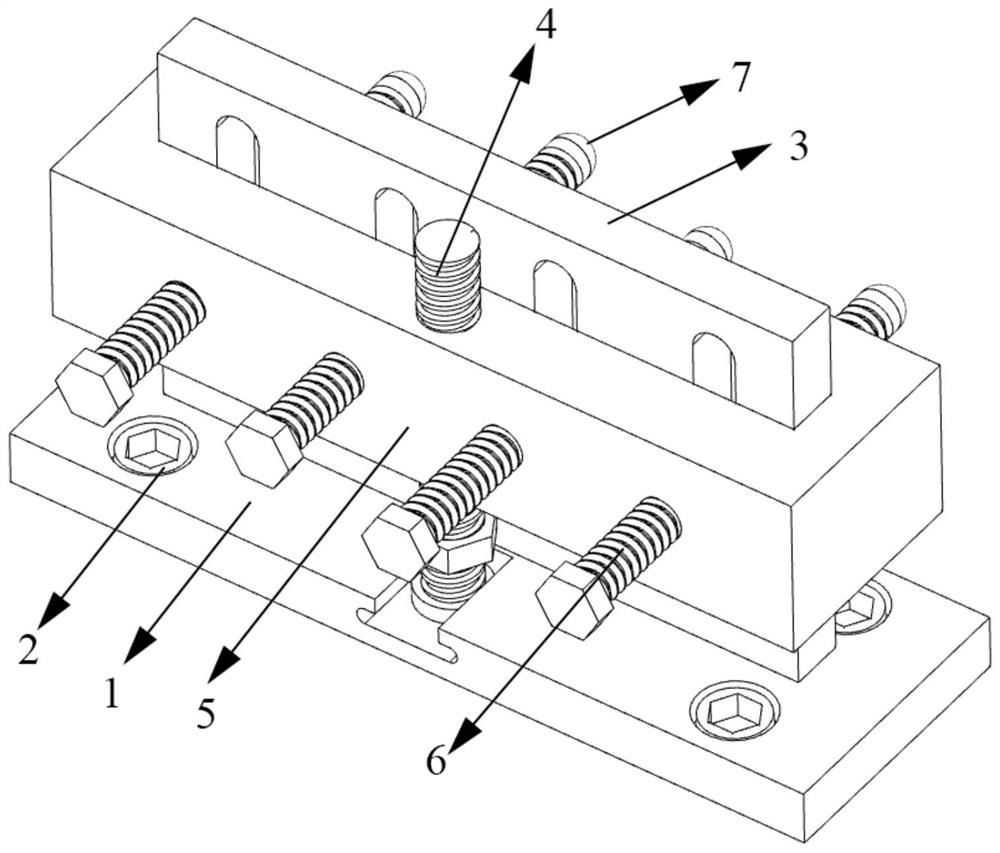

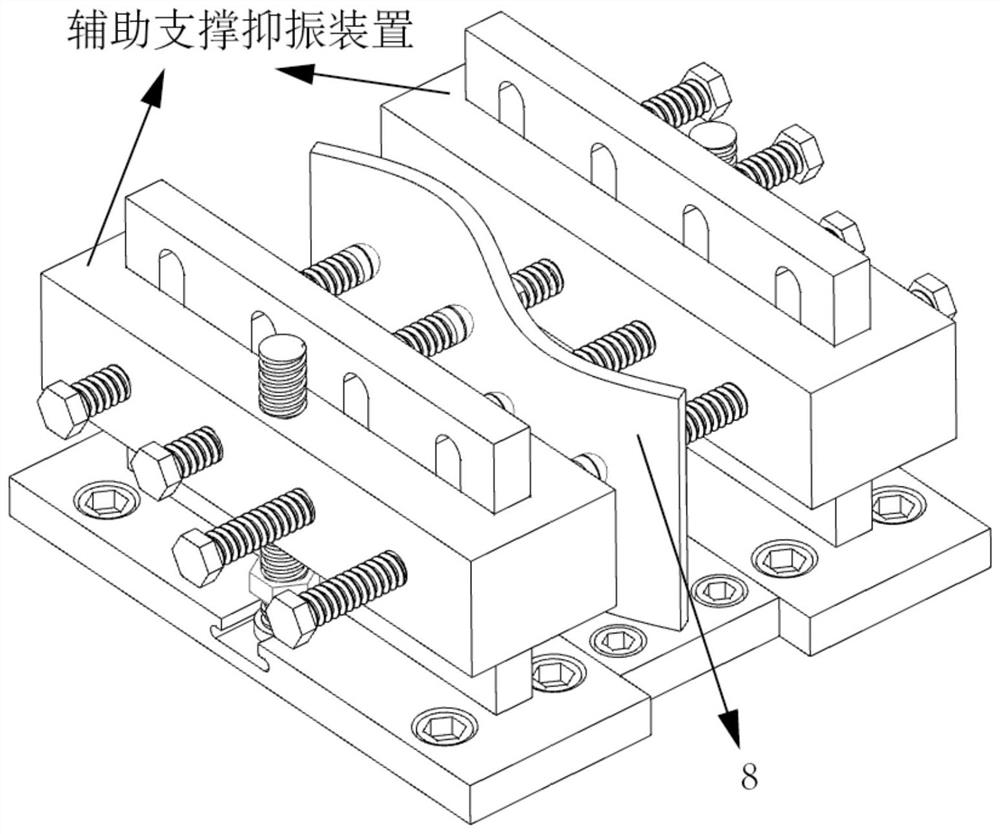

[0026] Such as figure 1 and 2 As shown, the auxiliary support and vibration suppression device of the present invention comprises a base 1, a base bolt 2, a support plate 3, an adjustment screw 4, an adjustment block 5, a support bolt 6, a rubber head 7 and a thin-walled curved surface part 8, wherein the adjustment The size of the rectangular through groove of the block 5 is equal to the peripheral rectangular size of the support plate 3, the width of the vertical groove in the support plate 3 is greater than or equal to the diameter of the support bolt 6, and the thread of the support bolt 6 matches the horizontal threaded hole of the adjustment block 5, The thread of the adjusting screw rod 4 matches the vertical threaded hole of the adjusting block 5, and the base 1 and the support plate 3 are integrated. Use the base bolt 2 to fix the base 1 on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com