Turning clamp for blind flange

A flange blind plate and turning technology, which is applied in the direction of turning equipment, turning equipment, manufacturing tools, etc., can solve the problems that affect the feeding of turning tools, and the three-jaw chuck cannot meet the needs of clamping flange blind plate blanks, etc. , to achieve the effect of improving turning accuracy, reducing clamping error and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

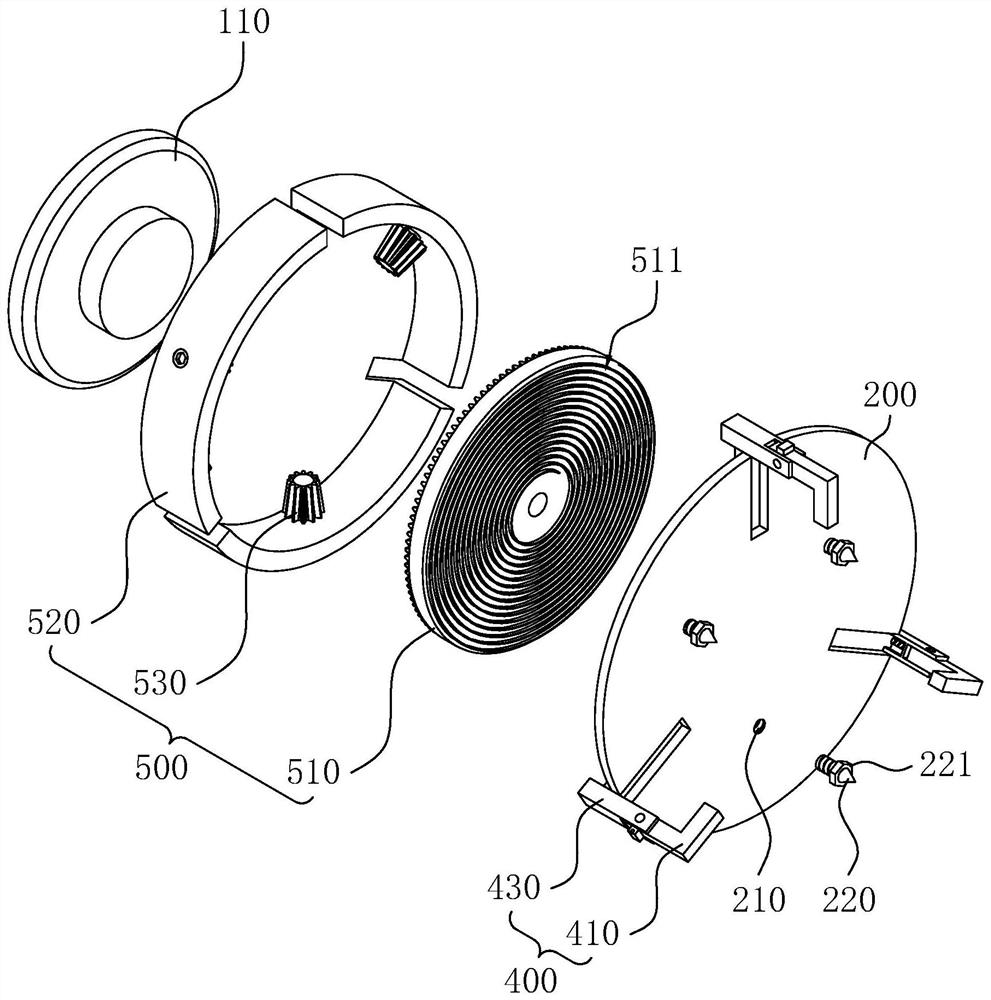

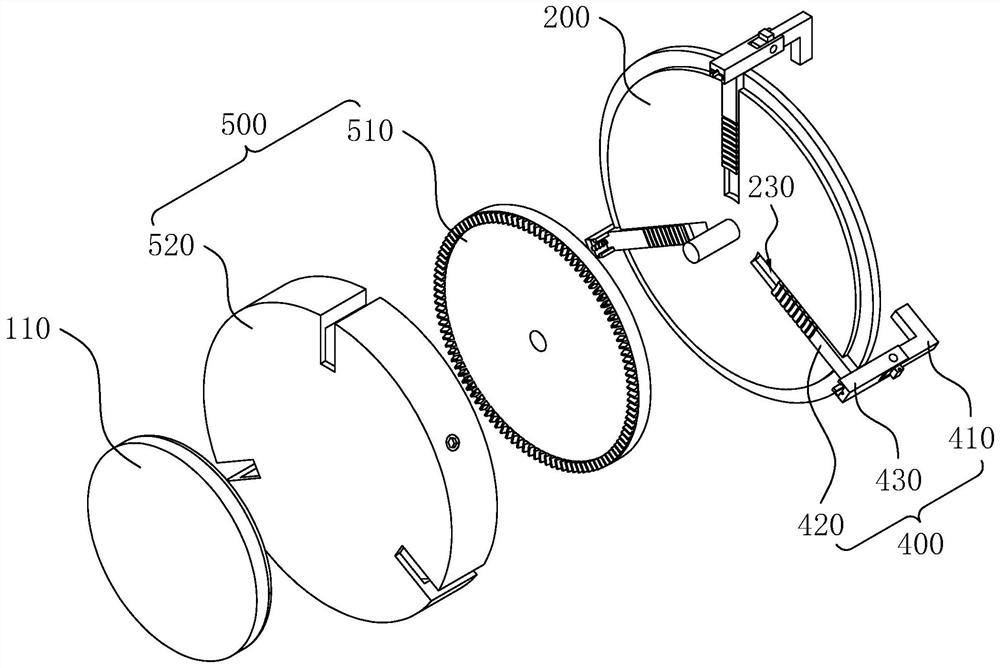

[0039] The following is attached Figure 1-6 The application is described in further detail.

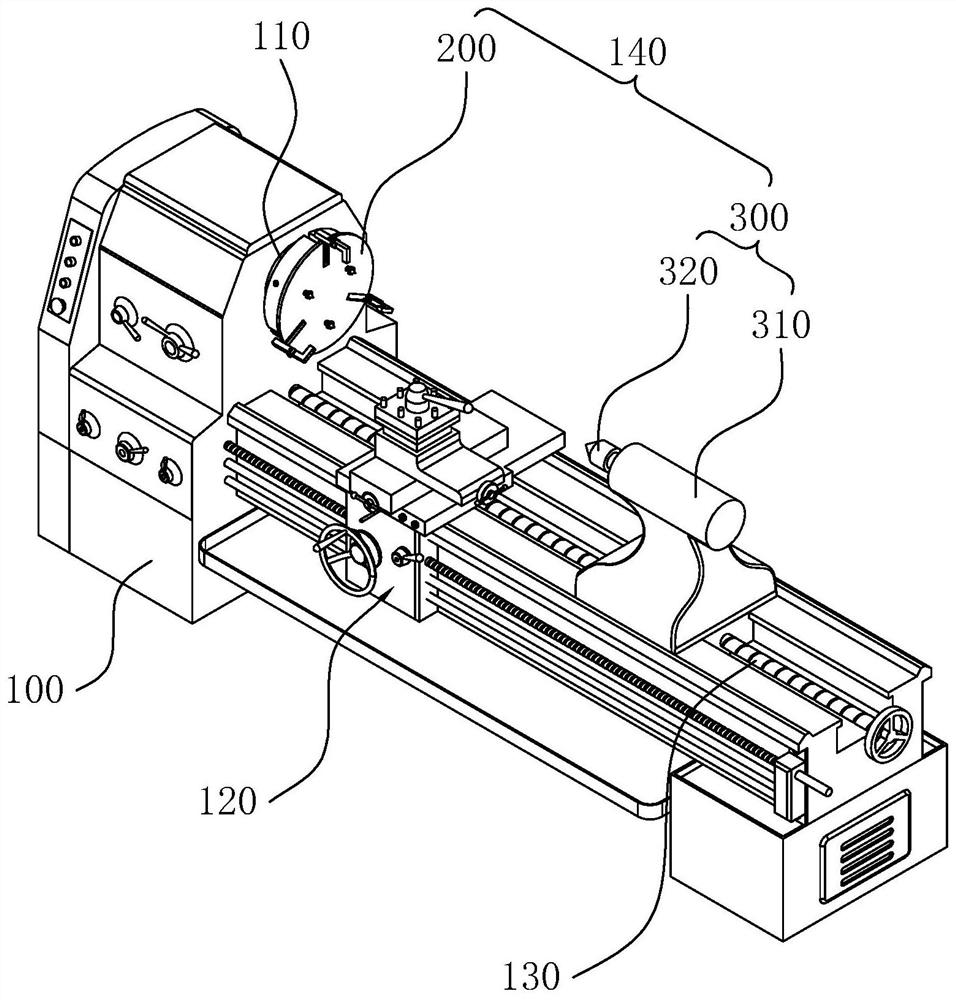

[0040] The embodiment of the present application discloses a turning fixture for a flange blind plate. refer to figure 1 and figure 2 , the turning jig 140 of the flange blind plate includes a base plate 200 as a basic support, a first pressing mechanism 300 and a second pressing mechanism 400 for pressing the blank. The base plate 200 is set on the spindle 110 of the lathe, the first edge mechanism is set on the frame 100 of the lathe, and the second pressing mechanism 400 is set on the base plate 200 .

[0041] refer to figure 1 and figure 2 , the base plate 200 has a circular cross-section, and the base plate 200 is coaxially fixedly connected to the spindle 110 of the lathe through a coupling. Most of the main shaft 110 of the lathe is coaxially fixed with a three-jaw chuck through a coupling. In other embodiments, the three-jaw chuck can also be used to clamp the subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com