A kind of culture medium maturation and sterilization equipment

A technology of sterilization equipment and culture medium, applied in gardening tools/equipment, botany equipment and methods, chemical instruments and methods, etc., can solve the problems of reducing the quality of medium aging and sterilization, and the effect of medium aging and sterilization is not up to standard, etc. , to achieve the effect of improving the effect and preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

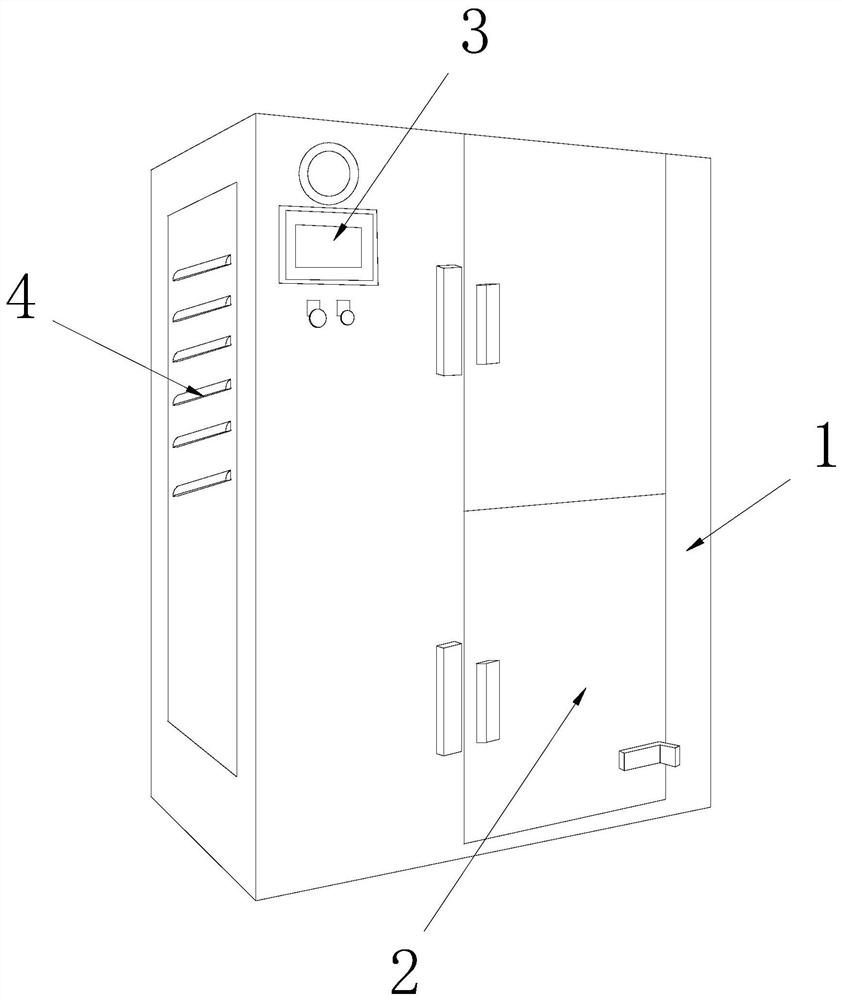

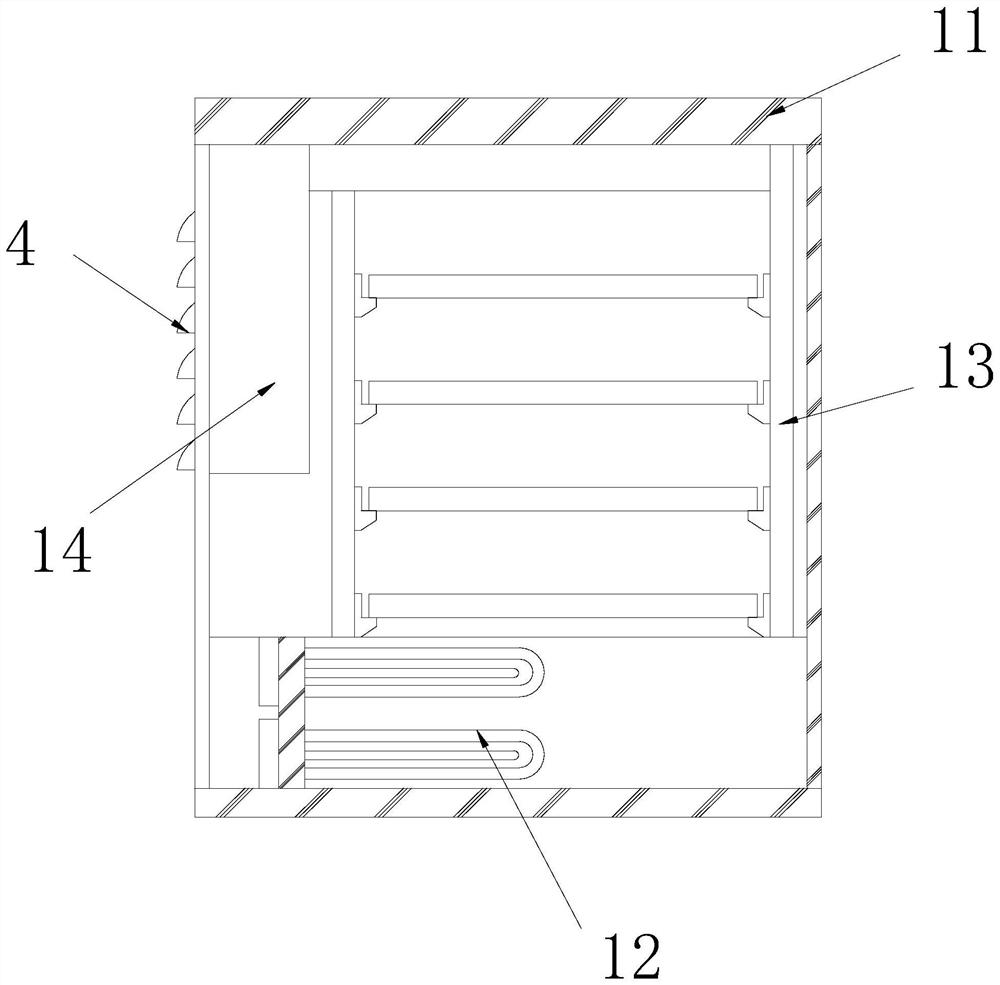

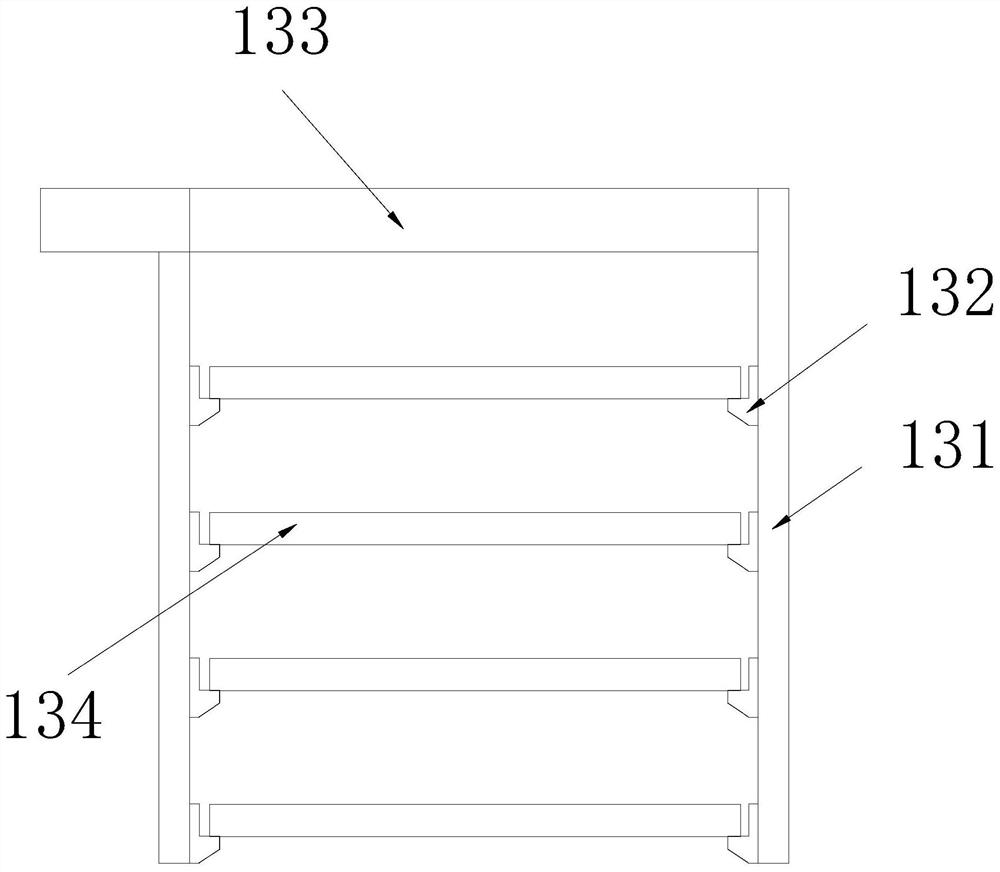

[0024] as attached figure 1 to the attached Figure 5 shown:

[0025] The present invention provides a culture medium maturation and sterilization equipment, the structure of which includes a cabinet body 1, a cabinet door 2, a controller 3, and a ventilation hole 4. The middle part of the cabinet body 1 is axially connected to the outer side of the cabinet door 2, and the controller 3 It is embedded and fixed with the upper side of the left end of the cabinet body 1. The ventilation hole 4 is bolted to the left side of the cabinet body 1. The cabinet body 1 includes a protective cover 11, a heater 12, a placement rack 13, and a radiator 14. The cover 11 is connected to the right side of the ventilation hole 4 in a snap connection, the heater 12 is connected to the inner side of the lower end of the protective cover 11 by welding, the placing frame 13 is connected to the inner side of the protective cover 11 by welding, and the radiator 14 is connected to the inner side of th...

Embodiment 2

[0032] as attached Image 6 to the attached Figure 7 shown:

[0033]The cleaning head b4 includes a through-hole cover b41, a spring b42, a collar b43, a threaded post b44, a movable block b45, and a scraping head b46. The outside of the through-hole cover b41 is in contact with the inside of the absorption block b2, so The spring b42 is connected to the inner side of the upper end of the through hole cover b41 by welding, the collar b43 is connected to the lower end of the spring b42 by welding, the threaded column b44 is embedded and connected to the upper end of the movable block b45, and the outer side of the movable block b45 is connected to the through hole cover b41. The inner side of the lower end is clearance fit, the scraping head b46 is welded to the outer side of the lower end of the movable block b45, the spring b42 is a spiral structure, and the material is carbon spring steel material, which has the characteristics of good thermal expansion performance, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com