Novel efficient ball mill

A ball mill, high-efficiency technology, applied in the direction of grain processing, etc., can solve the problems of ball mill roller shaking slightly, uneven force, ball mill efficiency and low quality, etc., to improve efficiency and quality, improve quality and efficiency, and improve practical experience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

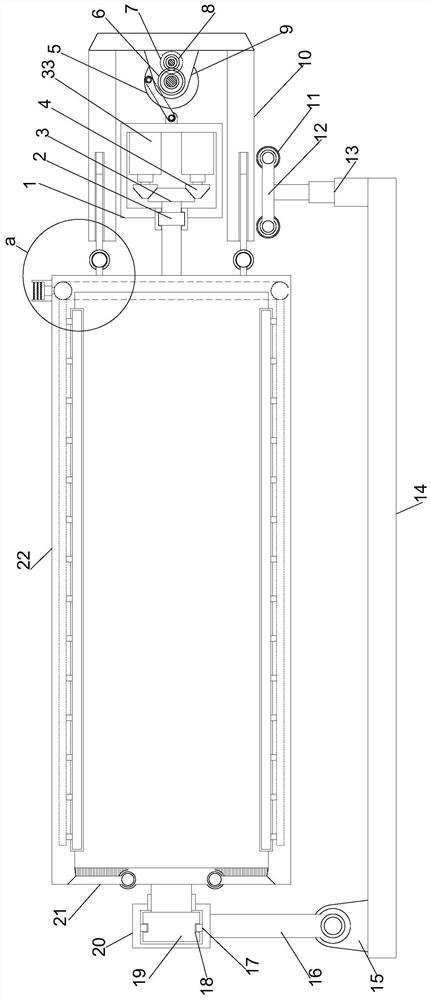

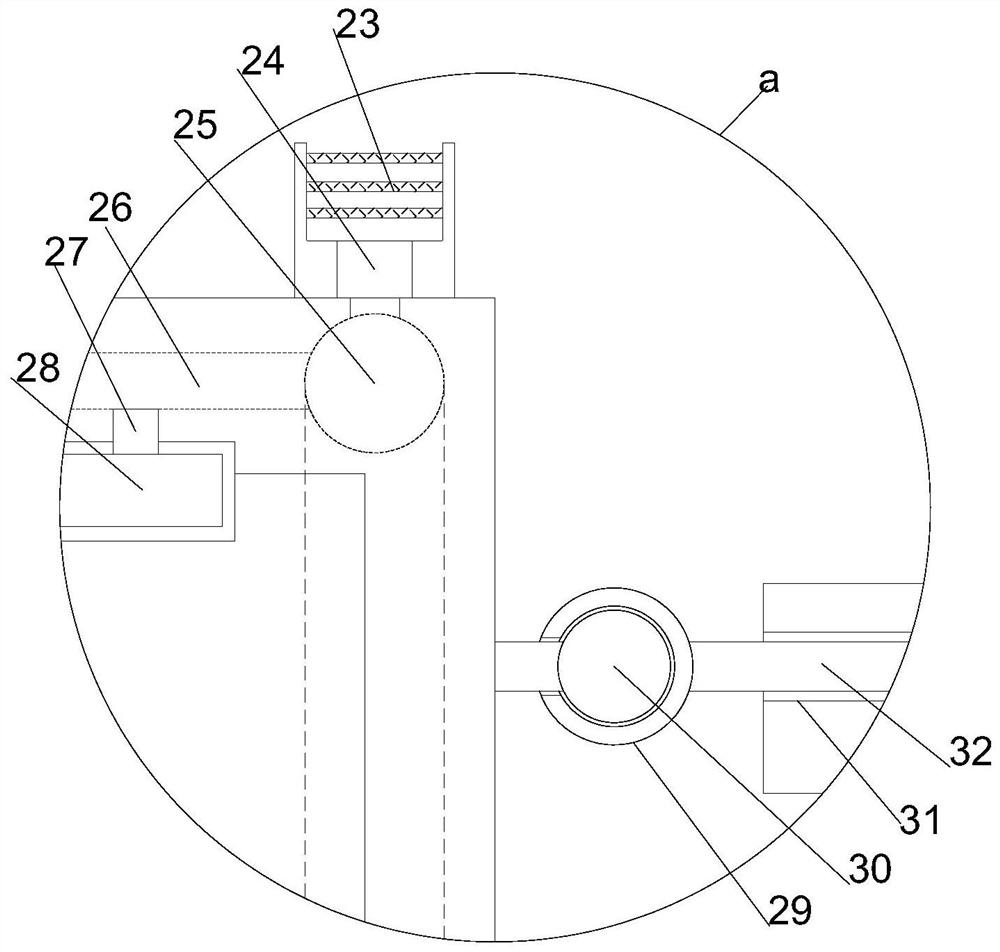

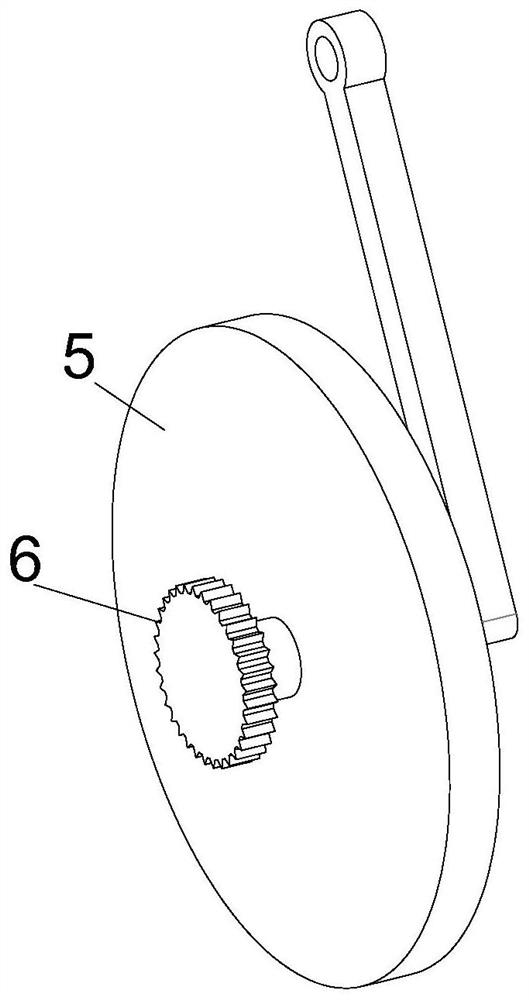

[0022] see Figure 1~3 , in the embodiment of the present invention, a new type of high-efficiency ball mill includes a support mounting plate 14 arranged horizontally, a rotating mounting cylinder 22 is arranged horizontally above the support mounting plate 14, and a support mounting frame is vertically provided at the upper left end of the support mounting plate 14 15. The upper end of the support installation frame 15 is provided with a support swing frame 16 through the rotating shaft, and the upper end of the support swing frame 16 is horizontally provided with a limit rotation sleeve 20, and the middle position of the left end of the rotation installation cylinder 22 cooperates with the limit rotation sleeve 20 to set a limit rotation column 19. The outer side of the limiting rotation column 19 is provided with a rotating conductive groove 18, and the inner side of the limiting rotating sleeve 20 is provided with a rotating conductive ring 17 in cooperation with the rotat...

Embodiment 2

[0025] On the basis of Embodiment 1, while the rotating installation cylinder 22 rotates, the cooperation between the rotating guide cylinder and the rotating installation ring 30 realizes the stable rotation of the rotating installation cylinder 22, while shaking, the orientation guide post 32 and the orientation guide hole Under the cooperation of 31, stable rocking is realized, and finally by the electric control lifting column 13, the tilting of the rotating installation cylinder 22 is realized, discharging is realized, and the ball milling operation is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com