Device and method for modifying pectin with dielectric barrier discharge cold plasma

A technology of dielectric barrier discharge and cold plasma, which is applied in discharge tubes, circuits, electrical components, etc., can solve the problems of unstable price, high production cost and high cost of enzyme modification method, achieve green, safe, efficient energy consumption, improve Effect of functional properties, good application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

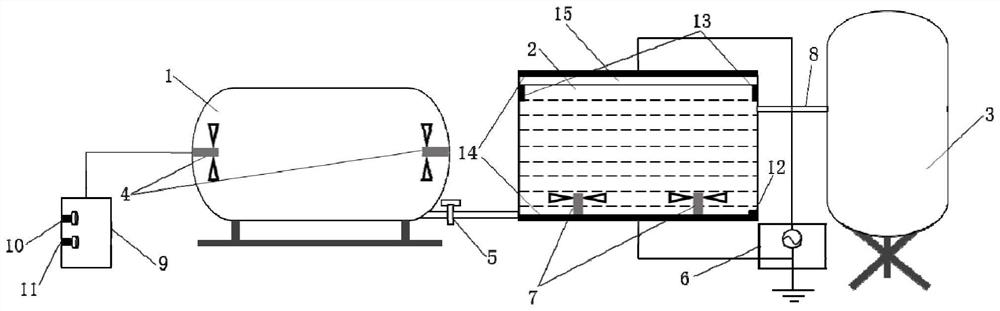

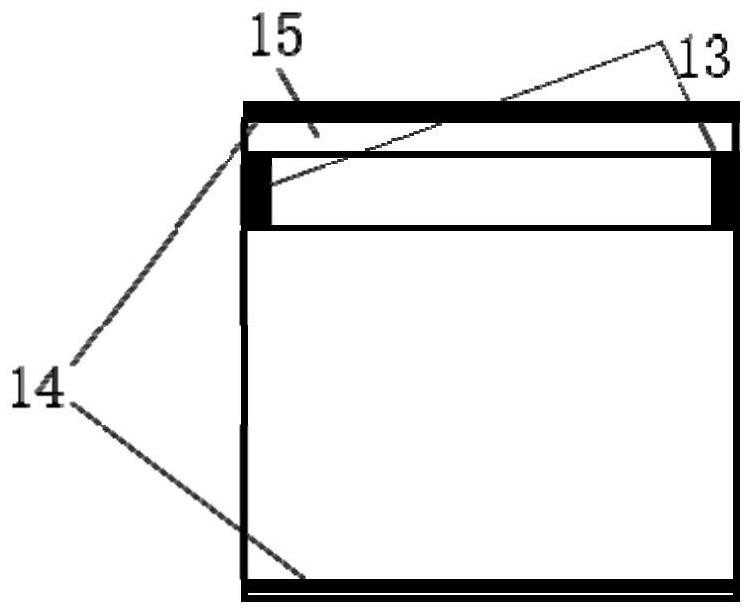

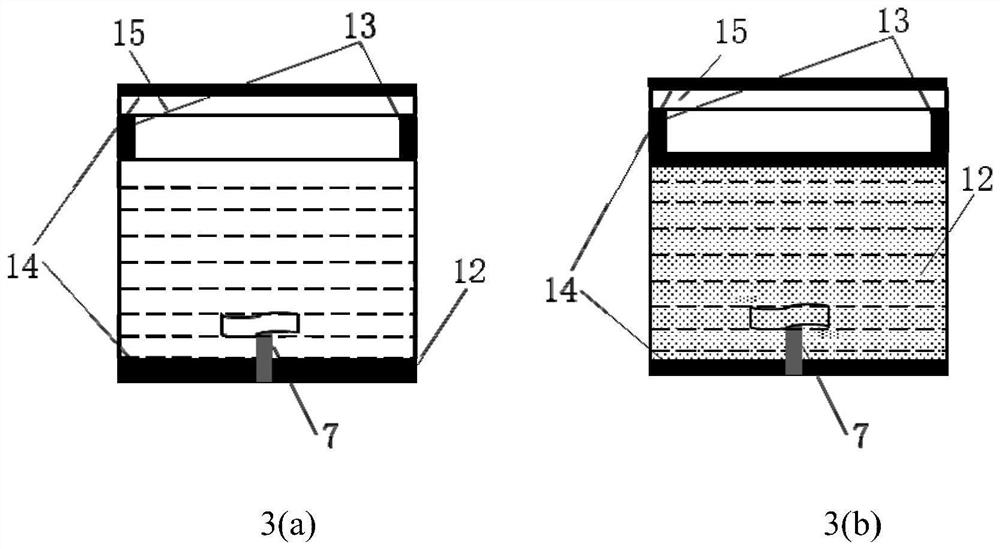

Method used

Image

Examples

Embodiment 1

[0050] The pectin solution with a concentration of 0.2% is configured through the first control chamber. After the first electric stirrer is turned on, the evenly mixed pectin solution is passed into the cold plasma treatment chamber through the valve, and the temperature between the two electrode plates is adjusted. Discharge pitch and fix height. Set the treatment voltage of the cold plasma treatment chamber to 40kV through the second control room, and the treatment time is 2min, and turn on the second electric stirrer. After the treatment is completed, the filter screen is raised, and after the filtration is completed, the plasma equipment is turned off. The filter screen is lowered, the pectin solution is passed into the drying chamber through a pipeline, and freeze-drying is selected, and the product yield of the pectin is 100%.

[0051] The molecular weight of citrus pectin before modification in this embodiment is 700kDa, the content of uronic acid is 74%, and the degre...

Embodiment 2

[0053] The pectin solution with a concentration of 0.2% is configured through the first control chamber. After the first electric stirrer is turned on, the evenly mixed pectin solution is passed into the cold plasma treatment chamber through the valve, and the temperature between the two electrode plates is adjusted. Discharge pitch and fix height. The processing voltage of the cold plasma processing chamber is set to 70 kV and the processing time is 2 min through the second control chamber, and the second electric stirrer is turned on. After the treatment, the filter screen is raised, and after the filtration is completed, the plasma equipment is turned off, the filter screen is lowered, the pectin solution is passed into the drying chamber through a pipeline, and freeze-drying is selected, and the pectin yield is 90%.

[0054] The molecular weight of citrus pectin before modification in this embodiment is 700kDa, the content of uronic acid is 74%, and the degree of esterific...

Embodiment 3

[0056] The pectin solution with a concentration of 0.4% is configured through the first control chamber. After the first electric stirrer is turned on, the evenly mixed pectin solution is passed into the cold plasma treatment chamber through a valve, and the temperature between the two electrode plates is adjusted. Discharge pitch and fix height. The processing voltage of the cold plasma processing chamber is set to 40 kV, the processing time is 2 min through the second control chamber, and the second electric stirrer is turned on. After the treatment, the filter screen is raised, and after the filtration is completed, the plasma equipment is turned off, the filter screen is lowered, the pectin solution is passed into the drying chamber through a pipeline, and freeze-drying is selected, and the yield of pectin is 100%.

[0057] The molecular weight of citrus pectin before modification in this embodiment is 700kDa, the content of uronic acid is 74%, and the degree of esterifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com