Method and system for producing high-activity-ratio Sr-89 and Sr-90 through liquid molten salt reactor

A SR-90, molten salt reactor technology, applied in the direction of reactor fuel material, reactor/accelerator external conversion, reduction of greenhouse gases, etc., can solve the problems of low production efficiency, high economic cost, low activity ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

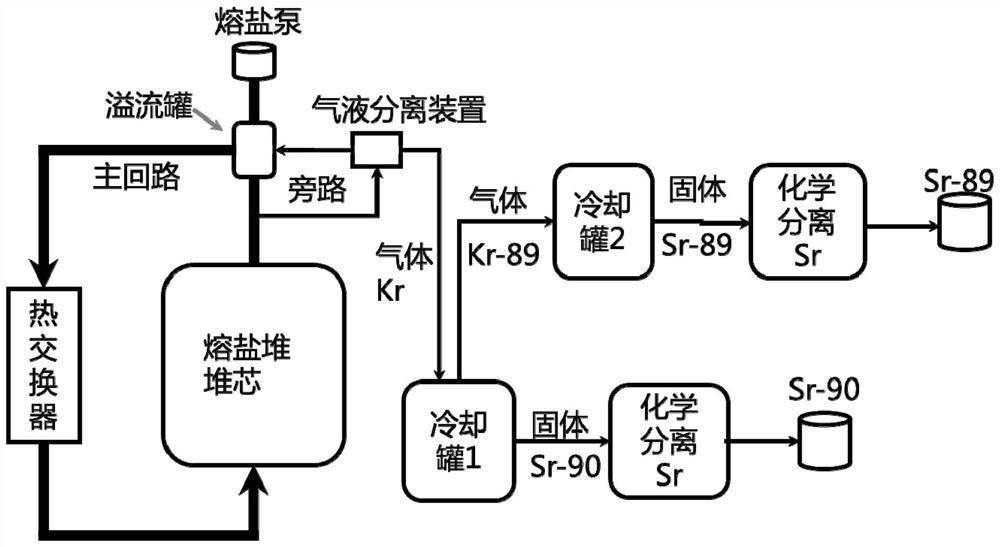

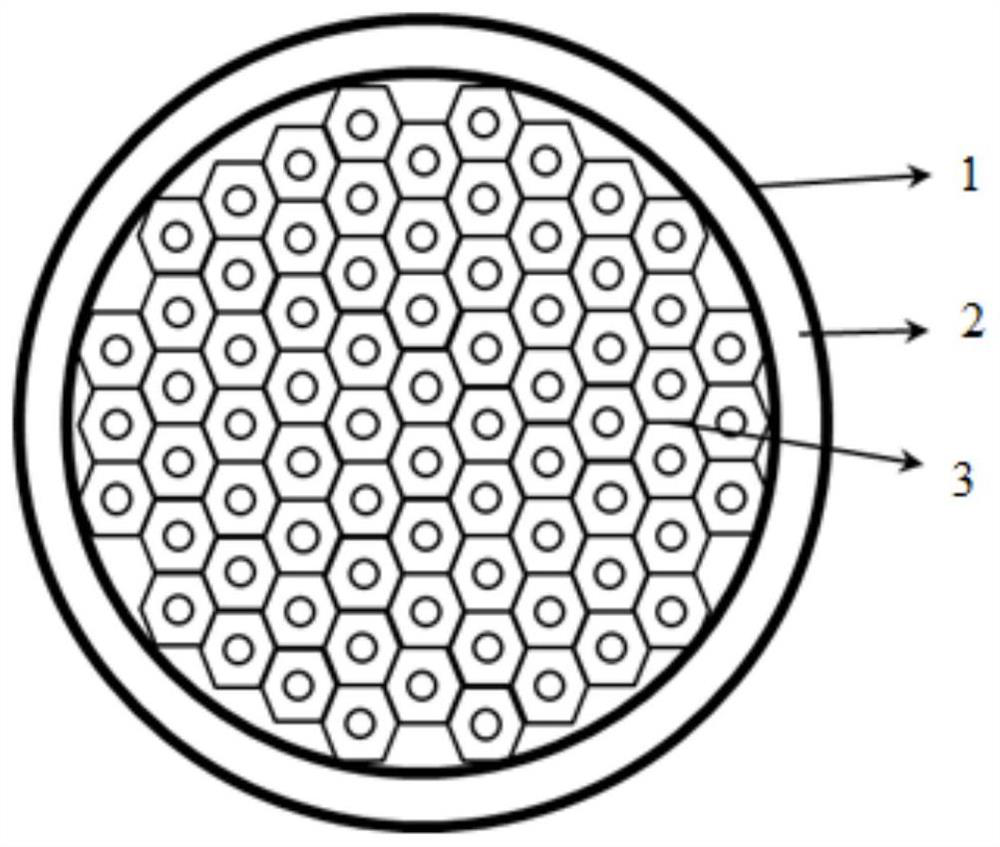

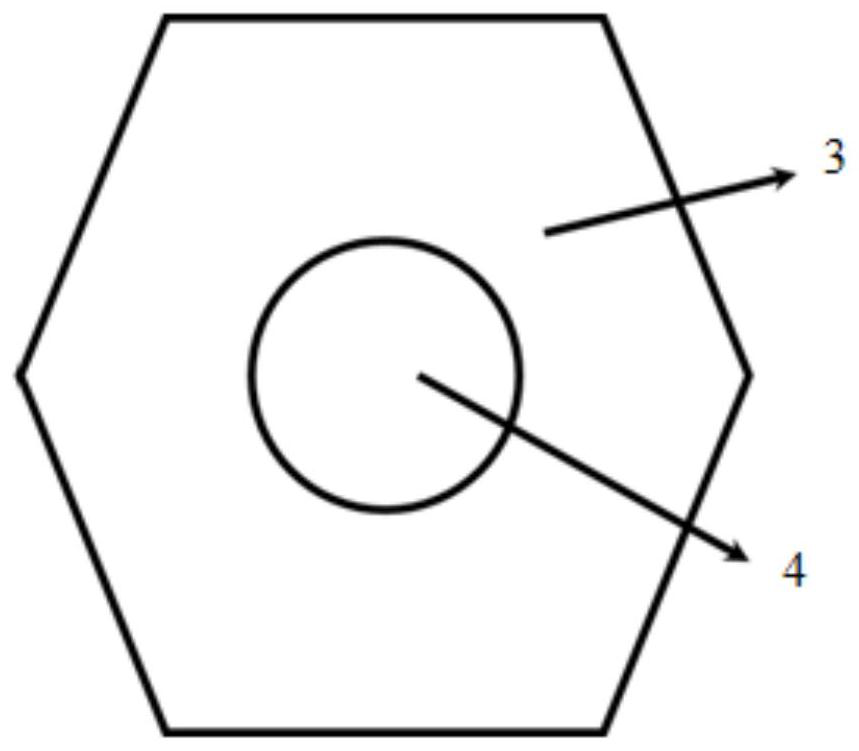

[0042] A molten salt composed of low-enrichment uranium and base salt is filled in the channel 4 of the graphite moderator component 3 , and the volume ratio of the molten salt to the graphite moderator component 3 is 1:5. Start the liquid molten salt reactor. During operation, the solid fission products are separated and recovered through the gas-liquid separation device in the bypass. The flow period of the molten salt in the bypass is 100s, and the gas-liquid separation efficiency is 95%. Collect uranium to maintain the reactor criticality at 1. The cooling time of the gas fission product in the cooling tank 1 is 6 minutes. The gas Kr-90 decays to generate solid Rb-90 and then produces Sr-90. The separation efficiency of Sr from the solid fission product is 90%. A 2MW liquid fuel molten salt reactor It can produce about 2000Ci of Sr-90 every year. Then blow the gas from the cooling tank 1 into the cooling tank 2, the cooling time is 100 minutes, then the annual production ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com