Manufacturing service resource dynamic scheduling method and system based on random online algorithm

A technology of manufacturing services and online algorithms, applied in the direction of manufacturing computing systems, resources, computing, etc., can solve problems such as inability to alleviate system load pressure, reduce system operating costs, and inability to personalize resource scheduling strategies, so as to improve CPU utilization, The effect of reducing CPU operating pressure and complete traversal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a method for dynamic scheduling of manufacturing service resources based on a random online algorithm;

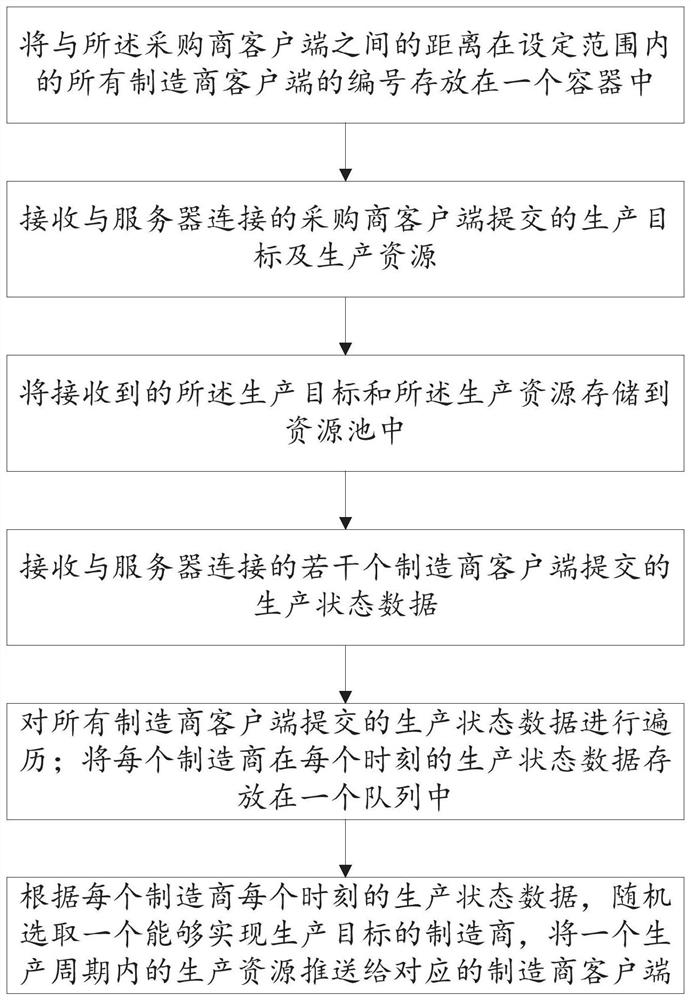

[0039] Such as figure 1 As shown, the dynamic scheduling method of manufacturing service resources based on random online algorithm is applied to the server, including:

[0040] S101: Store the serial numbers of all manufacturer clients whose distances to the buyer clients are within a set range in a container;

[0041] S102: Receive the production target and production resources submitted by the buyer client connected to the server;

[0042] S103: Store the received production target and the production resource in a resource pool;

[0043] S104: Receive production status data submitted by several manufacturer clients connected to the server;

[0044] S105: traverse the production status data submitted by all manufacturer clients; store the production status data of each manufacturer at each moment in a queue;

[0045] S106: According to ...

Embodiment 2

[0082] This embodiment provides a dynamic scheduling system for manufacturing service resources based on a random online algorithm;

[0083] A dynamic scheduling system for manufacturing service resources based on random online algorithms, including:

[0084] The storage module is configured to: store the serial numbers of all manufacturer clients whose distances from the buyer clients are within a set range in a container;

[0085] The first receiving module is configured to: receive the production target and production resources submitted by the buyer client connected to the server;

[0086] A storage module configured to: store the received production target and the production resource in a resource pool;

[0087] The second receiving module is configured to: receive production status data submitted by several manufacturer clients connected to the server;

[0088] The traversal module is configured to: traverse the production status data submitted by all manufacturer clie...

Embodiment 3

[0094] This embodiment also provides an electronic device, including: one or more processors, one or more memories, and one or more computer programs; wherein, the processor is connected to the memory, and the one or more computer programs are programmed Stored in the memory, when the electronic device is running, the processor executes one or more computer programs stored in the memory, so that the electronic device executes the method described in Embodiment 1 above.

[0095] It should be understood that in this embodiment, the processor can be a central processing unit CPU, and the processor can also be other general-purpose processors, digital signal processors DSP, application specific integrated circuits ASIC, off-the-shelf programmable gate array FPGA or other programmable logic devices , discrete gate or transistor logic devices, discrete hardware components, etc. A general-purpose processor may be a microprocessor, or the processor may be any conventional processor, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com