Fine dried noodle curing effect evaluation method based on extension displacement resistance in vertical rolling direction

A technology of calendering direction and evaluation method, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of difficult to judge accurately, cumbersome operation, long preparation time, etc., and achieve convenient and concise experimental process. , data processing is simple, the effect of small experimental variance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

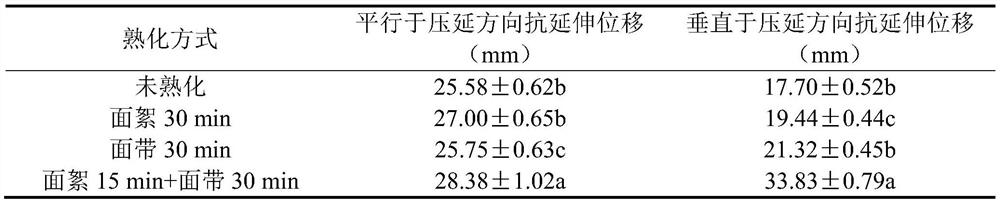

Embodiment 1

[0029] A method for evaluating the curing effect of dried noodles based on the anti-extension displacement in the vertical rolling direction, comprising the following steps:

[0030] Step (1) kneading dough: wheat flour is put into a dough kneading machine, and a certain amount of normal temperature salt water is evenly added while stirring, and the salt water is made by weighing table salt according to 2% of the total mass of wheat flour and dissolving it in water in advance; making the dough The final water content of the flocs is 34%, and the dough is kneaded for 10 minutes under normal pressure;

[0031] Step (2) ripening:

[0032] There are mainly four curing processes as follows:

[0033] Uncooked: The reconciled flour wadding is not processed, and the dough is rolled immediately after being transferred from the dough mixer;

[0034] Maturation of flour wadding: Transfer the reconciled flour wadding to a constant temperature and humidity box, cover it with a wet towel,...

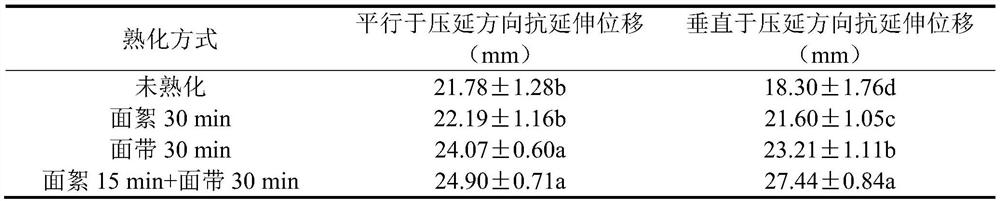

Embodiment 2

[0045] A method for evaluating the curing effect of dried noodles based on the anti-extension displacement in the vertical rolling direction, comprising the following steps:

[0046] Step (1) kneading dough: wheat flour is put into a dough kneading machine, and a certain amount of normal temperature salt water is evenly added while stirring, and the salt water is made by weighing table salt according to 2% of the total mass of wheat flour and dissolving it in water in advance; making the dough The final water content of the flocs is 34%, and the dough is kneaded for 10 minutes under normal pressure;

[0047] Step (2) ripening:

[0048] There are mainly four curing processes as follows:

[0049] Uncooked: The reconciled flour wadding is not processed, and the dough is rolled immediately after being transferred from the dough mixer;

[0050] Maturation of flour wadding: Transfer the reconciled flour wadding to a constant temperature and humidity box, cover it with a wet towel,...

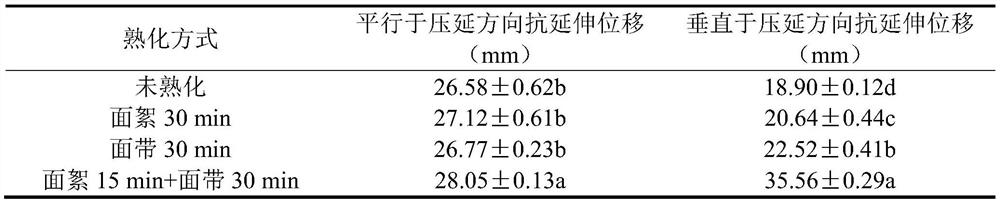

Embodiment 3

[0061] A method for evaluating the curing effect of dried noodles based on the anti-extension displacement in the vertical rolling direction, comprising the following steps:

[0062] Step (1) kneading dough: wheat flour is put into a dough kneading machine, and a certain amount of normal temperature salt water is evenly added while stirring, and the salt water is made by weighing table salt according to 2% of the total mass of wheat flour and dissolving it in water in advance; making the dough The final water content of the flocs is 34%, and the dough is kneaded for 10 minutes under normal pressure;

[0063] Step (2) ripening:

[0064] There are mainly four curing processes as follows:

[0065] Uncooked: The reconciled flour wadding is not processed, and the dough is rolled immediately after being transferred from the dough mixer;

[0066] Maturation of flour wadding: Transfer the reconciled flour wadding to a constant temperature and humidity box, cover it with a wet towel,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com