Hollow flame low-nitrogen burner

A low-nitrogen burner, hollow technology, applied in the direction of burner, gas fuel burner, combustion method, etc., can solve the problems of easy vibration, condensed water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

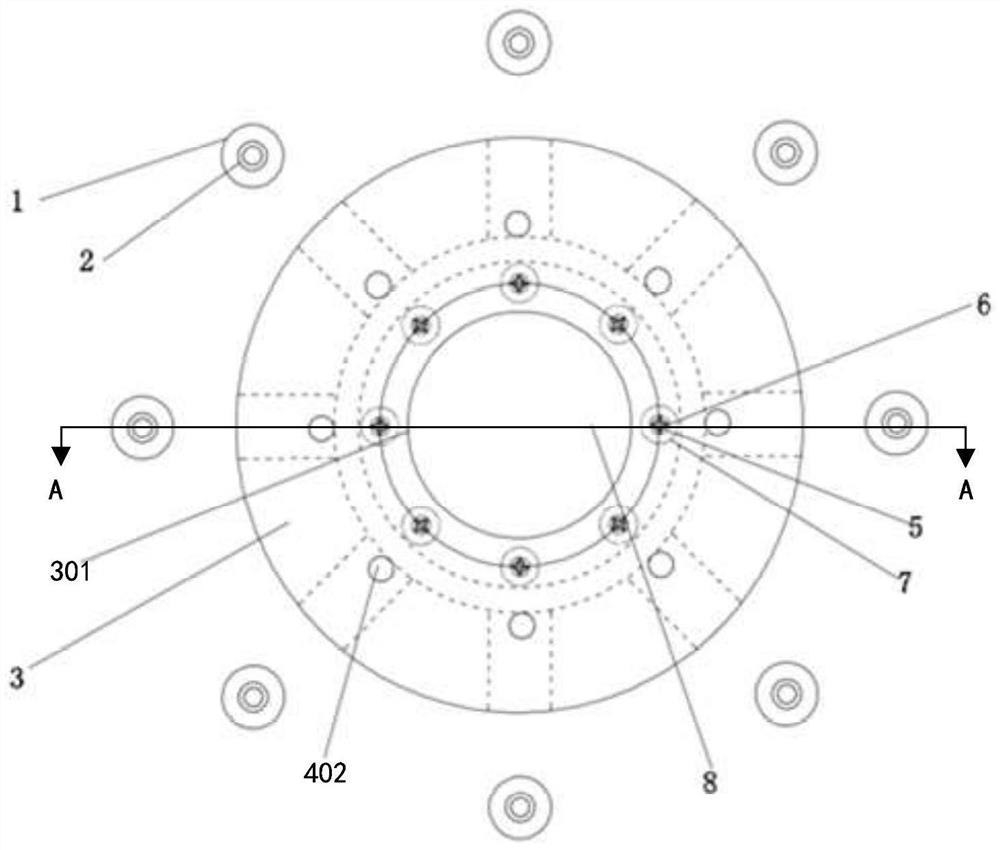

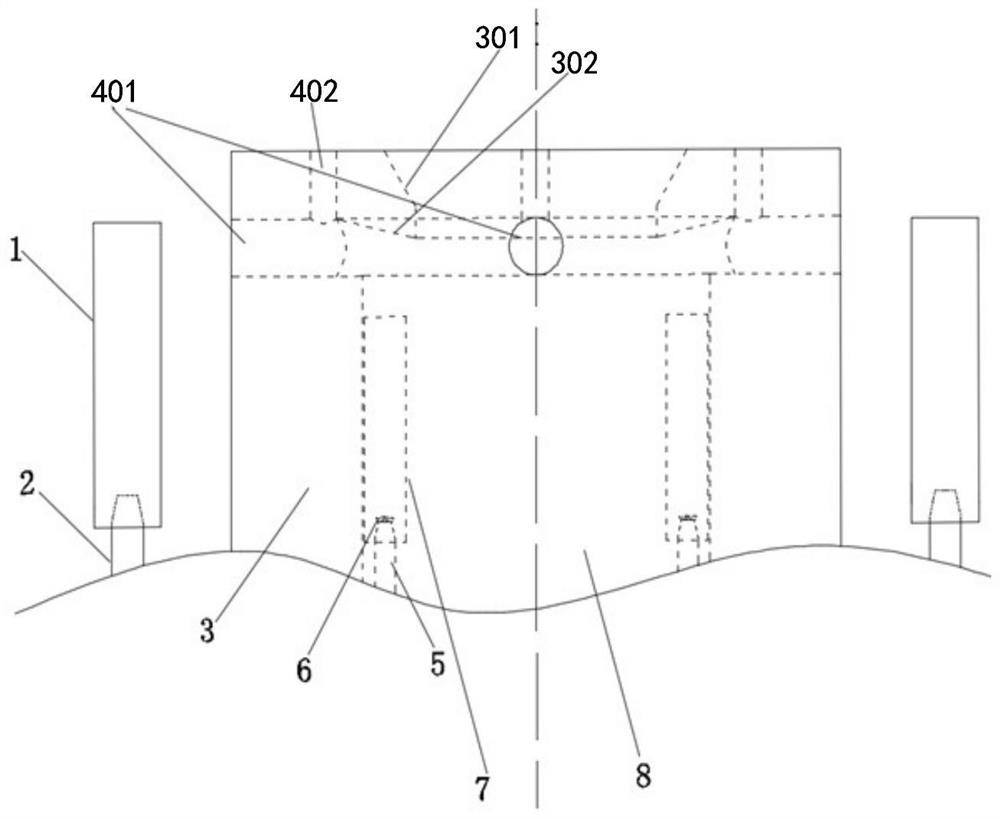

[0034]see Figure 1 to Figure 3 As shown, the present invention provides a hollow flame low-nitrogen burner, including: a casting material platform 3, the casting material platform 3 includes opposite first surfaces and second surfaces, and an air channel is formed inside the casting material platform 3 8. The air channel 8 extends from the first surface to the second surface; the inner gas air channel 7 is located between the air channel 8 and the pouring material table 3, and the inner gas air channel 7 Parallel to the air channel 8; the inner gas channel 5 extends from the first surface to the inner gas air channel 7; the inner gas nozzle 6 is located at the inner gas channel 5 and extends to the inner gas air channel One end in 7; the first flue gas channel 401 of the castable platform is located in the castable platform 3, one end communicates with the air channel 8, and the other end extends to the outer wall of the castable platform 3; the castable platform The second ...

Embodiment 2

[0038] read on Figure 1 to Figure 3 , A hollow flame low nitrogen burner is also provided in this embodiment. Compared with the hollow flame low nitrogen burner in Embodiment 1, the hollow flame low nitrogen burner in this embodiment also includes the following structure:

[0039] As an example, the number of the internal gas air channels 7, the number of the internal gas channels 5, the number of the internal gas nozzles 6, the number of the first flue gas channels 401 of the castable table, the number of the castable table The number of the second flue gas channel 402, the number of the outer gas flue gas mixing channel 1 and the number of the outer gas channel 2 are multiple; the inner gas air channel 7 and the inner gas channel 5 are one by one Correspondingly arranged, a plurality of the internal gas air passages 7 and a plurality of the internal gas passages 5 are arranged at intervals in the circumferential direction with the centerline of the hollow flame low nitrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com