Furnace body of vaporized fuel oil combustion furnace

A combustion furnace and fuel oil technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of incomplete combustion of vaporized fuel oil, inconvenient use, incomplete vaporization of fuel oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

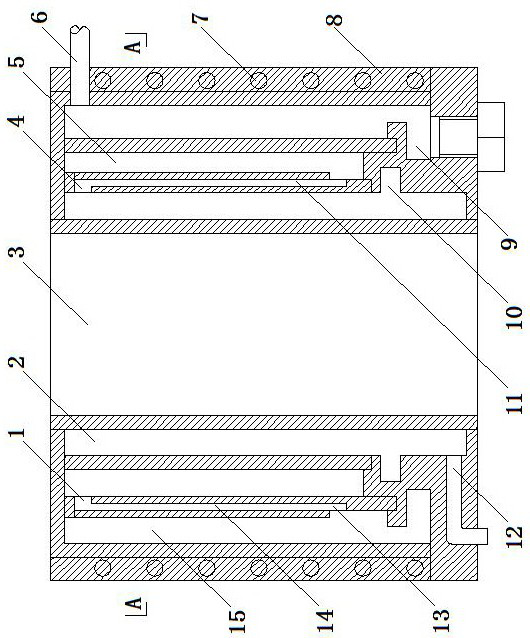

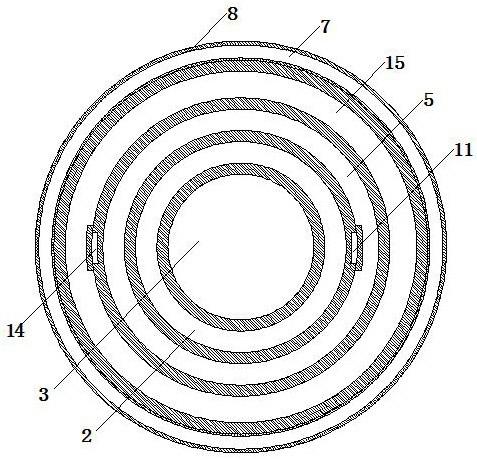

[0029] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0030] Such as figure 1 , figure 2 As shown, the body of the gasification fuel burner of the present invention includes a combustion chamber 3, and also includes a vaporization chamber and an electric heating device. The vaporization chamber includes a primary chamber 2 and a final chamber 15 . The primary chamber 2 is arranged around the combustion chamber 3, and the bottom of the primary chamber 2 is provided with an inlet 12 communicating with vaporized fuel. The lower side wall of the primary chamber 2 is preferably provided with an annular carbon deposition tank 10, which is used for fuel preheating in the primary chamber to generate carbon deposition and accumulate in the annular carbon deposition tank to prevent carbon deposition from blocking the gas channel. The final cavity 15 is arranged around the primary cavity 2 and communicated with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com