Non-welding elastic sealing pipe joint

An elastic sealing tube and elastic sealing technology, which is applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing components, etc., can solve the problems of many parts, large installation torque, and influence on popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

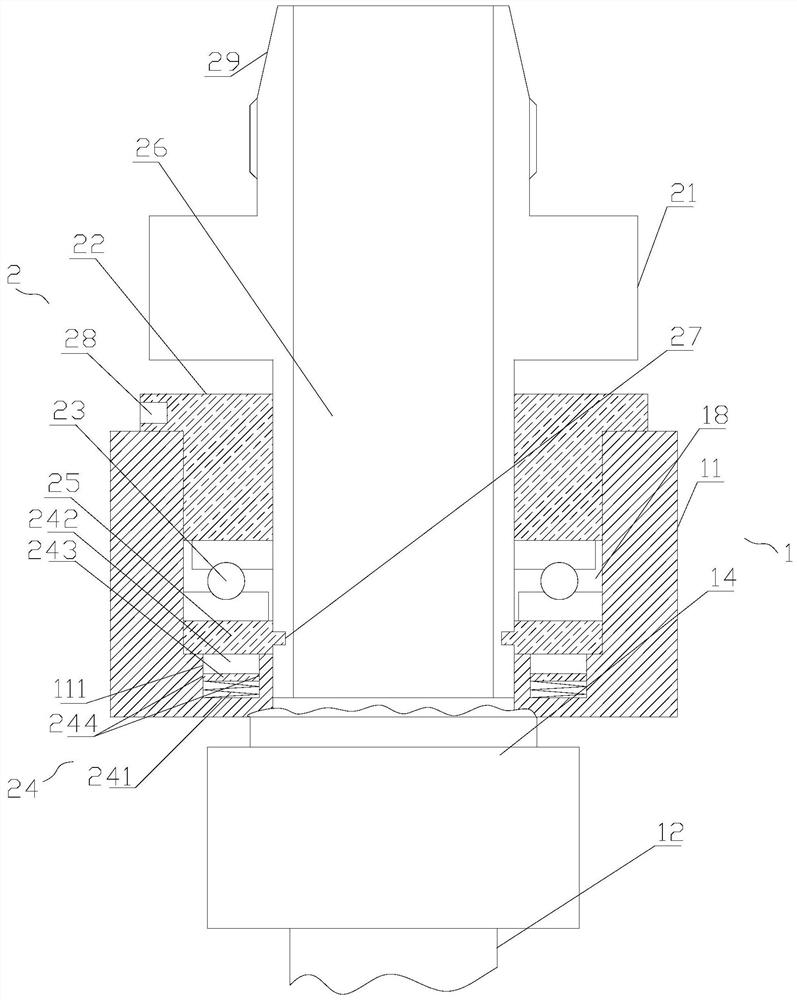

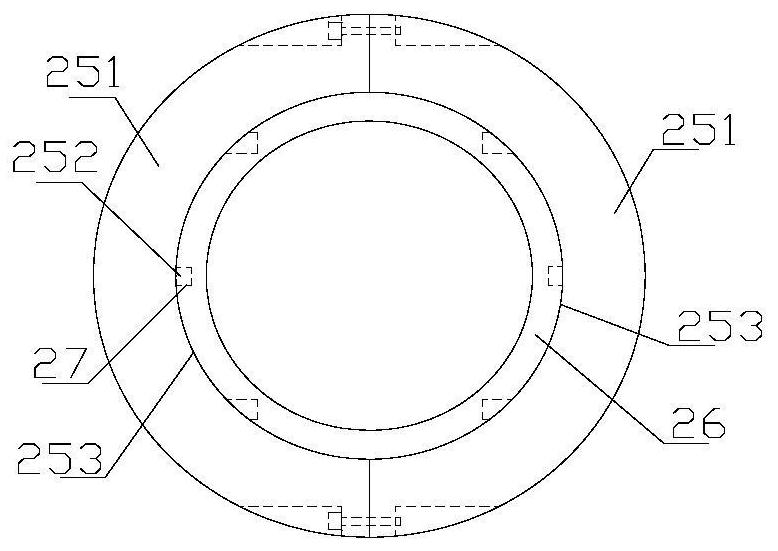

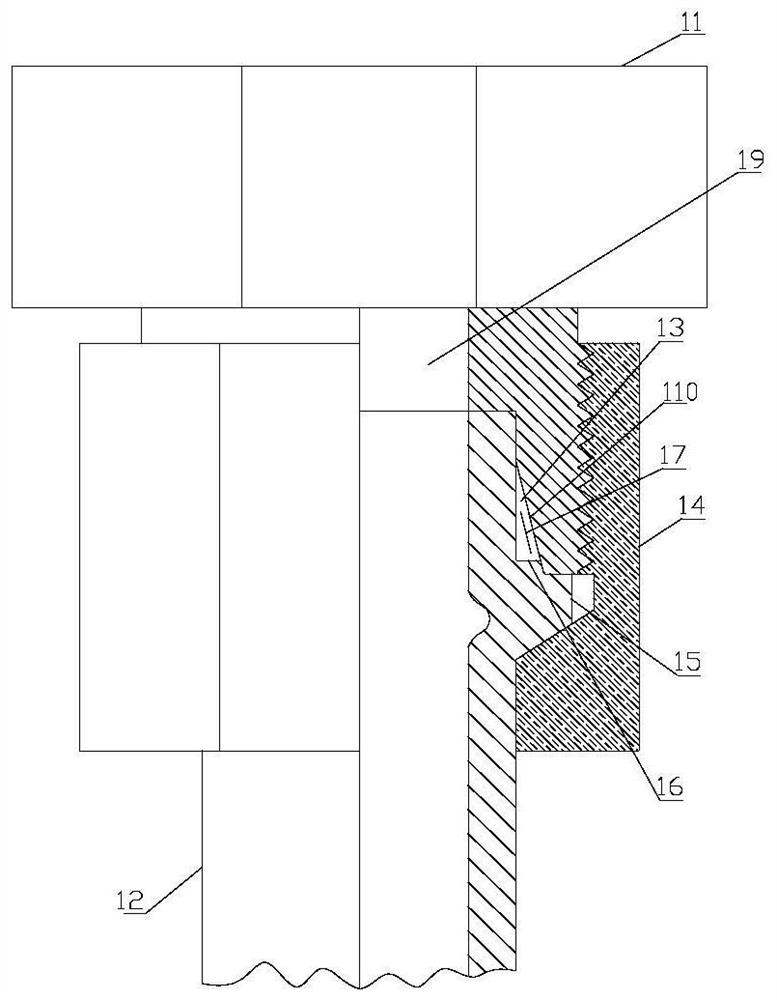

[0019] refer to figure 1 , figure 2 , image 3 and Figure 4 , a non-welding elastic sealing pipe joint of the present invention, comprising a first connecting head 1 and a second connecting head 2 rotatably connected to the first connecting head 1, the first connecting head 1 includes a T shape with a large top and a small bottom. Joint body 11, pipe 12, elastic sealing ring 13 and nut 14, the upper end of the T-shaped joint body 11 is provided with a threaded hole 18, and the lower end of the T-shaped joint body 11 is provided with a stepped hole 19 with a lower portion and an upper portion. The step hole 19 communicates with the threaded hole 18, the lower end of the step hole 19 is a tapered hole 110, the pipe end of the pipeline 12 is formed with a ring-shaped anti-off protrusion 15 through a cold forming process, and the ring-shaped anti-slip The pipeline 12 above the protrusion 15 is provided with an elastic sealing ring 13 matched with the tapered hole 110, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com