SMA-based self-resetting assembly type steel plate shear wall and construction and installation method thereof

A technology for steel plate shear walls and installation methods, applied to walls, protective buildings/shelters, building components, etc., can solve the buckling of non-stiffened thin steel plate shear walls, increase the difficulty of post-earthquake repairs, and initial stiffness The problem of falling too much can be improved to improve the lateral stiffness, prevent the destructive collapse of the structure, and reduce the interstory displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

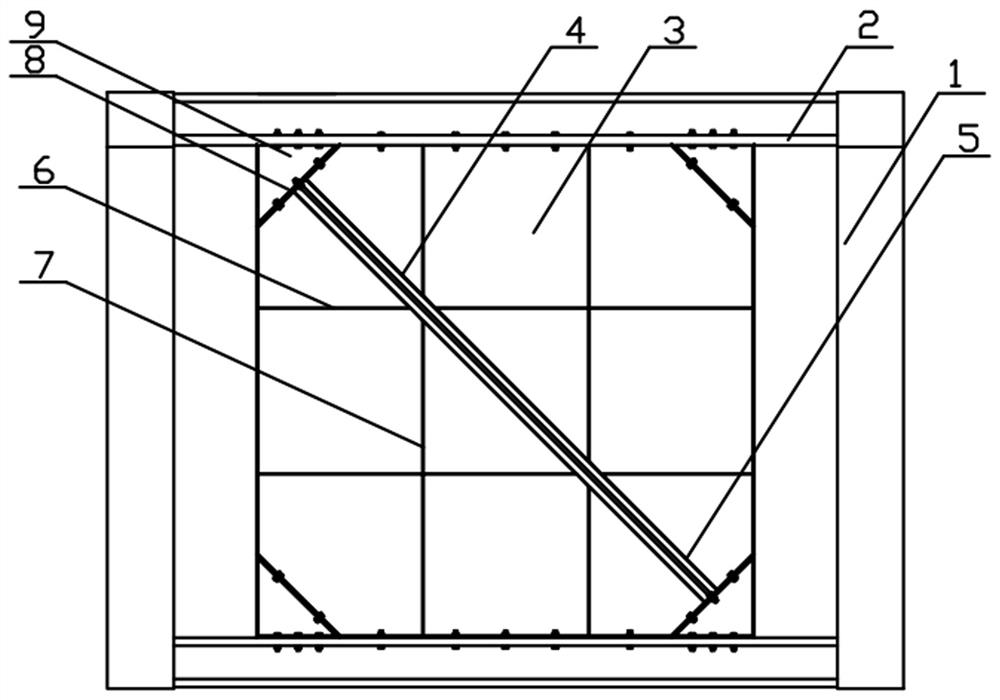

[0047] This embodiment provides a self-resetting assembled steel plate shear wall based on SMA, which includes two structural columns 1, at least two I-beams 2 are arranged in parallel between the two structural columns 1, and any adjacent two An embedded steel plate 3 is installed between the root I-shaped steel beams 2, and the embedded steel plate 3 has at least one set of parallel opposite sides; a set of parallel opposite sides of the embedded steel plate 3 are fixed on two On the I-beam 2, there is a distance between the structural column 1 and the embedded steel plate 3;

[0048] The embedded steel plate 3 is also provided with an SMA strand 5 unit, the SMA strand 5 unit includes an SMA strand channel 4 and an SMA strand 5, and the SMA strand channel 4 includes two parallel Stiffeners on the embedded steel plate 3, the SMA stranded wire 5 is located in the SMA stranded wire channel 4, and the two ends are respectively fixed on the embedded steel plate 3 and the SMA stra...

Embodiment 2

[0064] The difference between this embodiment and Embodiment 1 is that: the SMA strand 5 units are arranged on both sides of the embedded steel plate 3, and the SMA strand 5 units located on one side of the embedded steel plate 3 are connected to the The SMA strand 5 units on the other side of the embedded steel plate 3 intersect in space.

[0065] The SMA strand channels 4 are arranged on both sides of the embedded steel plate 3, forming cross stiffeners in a disguised form, further improving the lateral stiffness of the embedded steel plate 3, and at the same time making the SMA strands 5 on both sides alternately stretched and compressed without interfering with each other .

Embodiment 3

[0067] The difference between this embodiment and embodiment 2 is: as figure 2 with image 3 As shown, the self-resetting assembled steel plate shear wall also includes a plurality of auxiliary connection devices 9, the first side of the auxiliary connection device 9 is bolted to the I-beam 2, and the auxiliary connection device 9 The second side of the second side is bolted to an edge stiffener 8 of the embedded steel plate 3; the second side of the auxiliary connecting device 9 is also fixed with one end of the SMA strand 5.

[0068] Due to the arrangement of the auxiliary connection device 9, the contact area between the polygonal embedded steel plate 3 and the I-beam 2 is wider, and the connection between the polygonal embedded steel plate 3 and the I-beam 2 is more reliable.

[0069] In a specific implementation, the auxiliary connection device 9 includes a triangular steel plate and a right-angled triangular frame body welded by three-sided steel plates, and the triang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com