Bidirectional plate stressed longitudinal and transverse beam concrete superstructure of level crossing bridge

A technology of vertical and horizontal beams and level crossings, applied in bridges, bridge parts, bridge construction, etc., can solve the problem that the temporary structure of simple level crossings cannot cope with complex road conditions, the temporary bridge structure of simple level crossings has a short service life, and the cost of interchangeable interchanges is expensive, etc. problems, to achieve the effect of major production practical significance, convenient and safe travel, and ensuring safe and smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

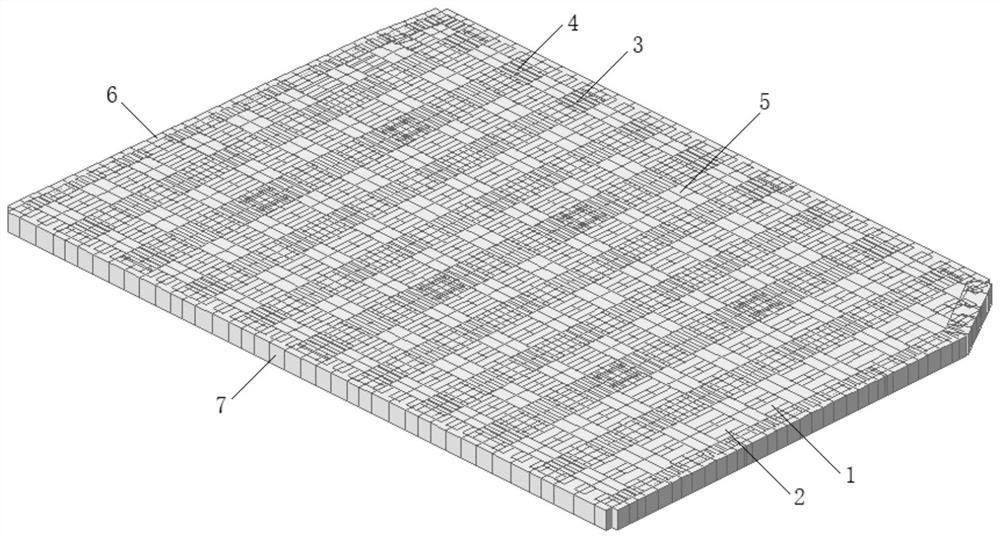

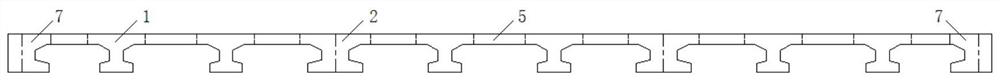

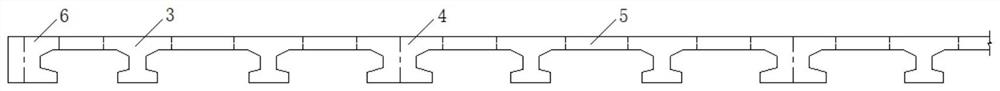

[0038] as attached Figure 1 to Figure 13 As shown, a two-way slab-loaded longitudinal and beam concrete superstructure of a level crossing bridge is applied to vehicles and pedestrians in different driving directions on various intersecting roads at urban level crossings. As the upper girder structure of the permanent level crossing bridge, the present invention is mainly applied to crossing positions in different directions on the bridge, including three parts: the longitudinal and horizontal beam structure system, the roof structure system, and the side beam structure system.

[0039] The edge beam structural system encloses a space. The vertical and horizontal beam structural system is arranged in the space surrounded by the side beam st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com