Quenching heating device and workpiece fixing unit thereof

A technology of fixing unit and heating device, applied in the field of quenching heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

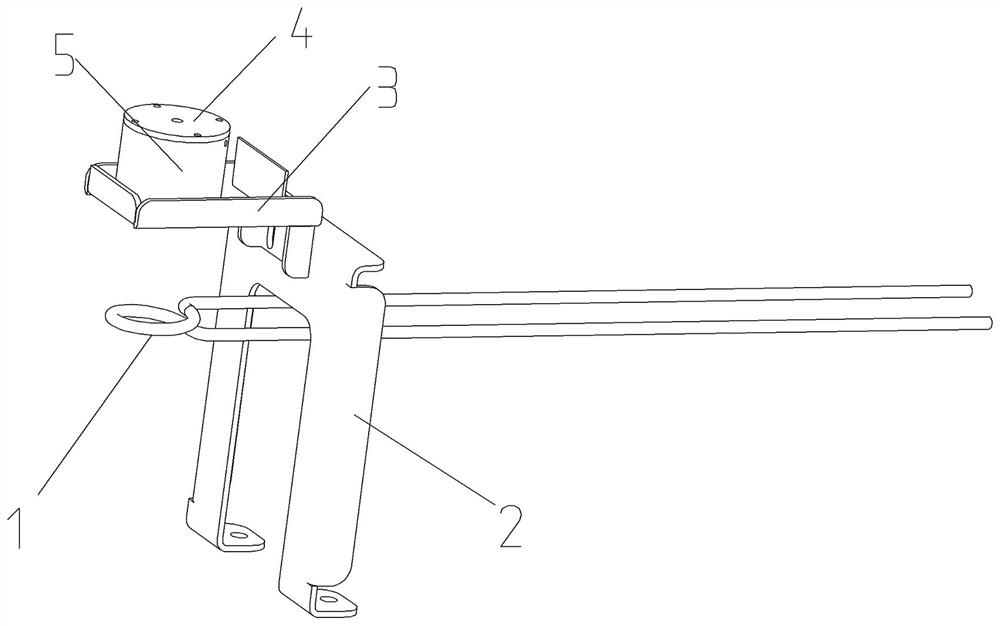

[0058] Such as Figure 1 to Figure 3 As shown, the quenching heating device in this embodiment mainly includes two parts, namely the induction heating coil 1 and the workpiece fixing unit. The workpiece fixing unit is an electromagnetic adsorption fixing structure. The heating coil 1 is absorbed and fixed by the electromagnetic adsorption fixing structure, and the workpiece to be quenched is heated by the induction heating coil 1. After the set heating time, the electromagnetic adsorption structure no longer adsorbs the workpiece to be quenched, and the workpiece to be quenched falls into the corresponding In the quenching liquid tank, it is cooled by the quenching liquid to realize quenching heat treatment.

[0059] In this embodiment, the induction heating coil 1 is a high-frequency coil on the equipment host of the existing quenching equipment, and copper tubes are usually used to meet the frequency requirements of the current loaded on the induction heating coil. After th...

specific Embodiment 2

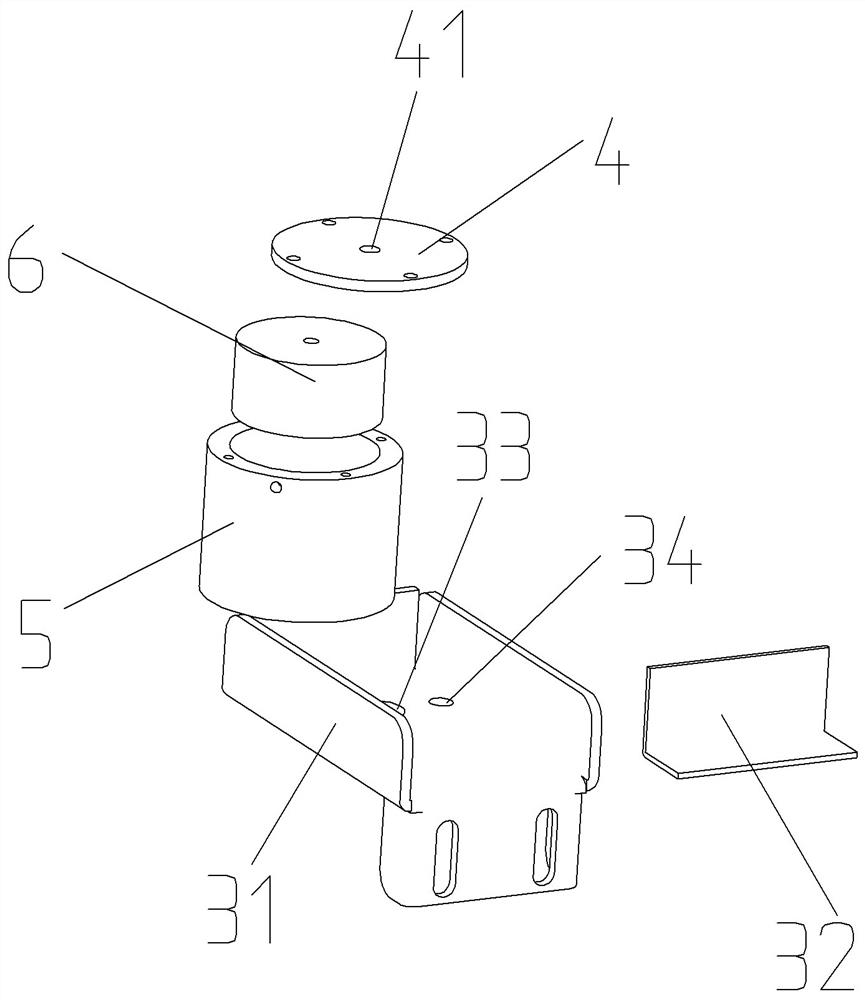

[0077] It differs from Example 1 mainly in that in the quenching heating device in Example 1, the guide sleeve is cooled by an external water tank. In this example, as Figure 4 with Figure 5 As shown, the guide sleeve 5 itself has an annular groove 11, and the annular groove is used to store cooling liquid for cooling.

[0078] Specifically, the guiding sleeve in this embodiment is the same as the guiding sleeve in Embodiment 1 in that they all have a stepped hole structure, the large diameter section 14 of the stepped hole structure is used to place the electromagnetic chuck, and the small diameter section 11 is used for To guide the assembly of the workpiece to be quenched, it is also necessary to install the corresponding suction cup cover plate to press and fix the electromagnetic chuck during assembly.

[0079] It should be noted that, in this embodiment, the ring groove 11 of the guide sleeve 5 is arranged around the large-diameter section 14 of the stepped hole for c...

specific Embodiment 3

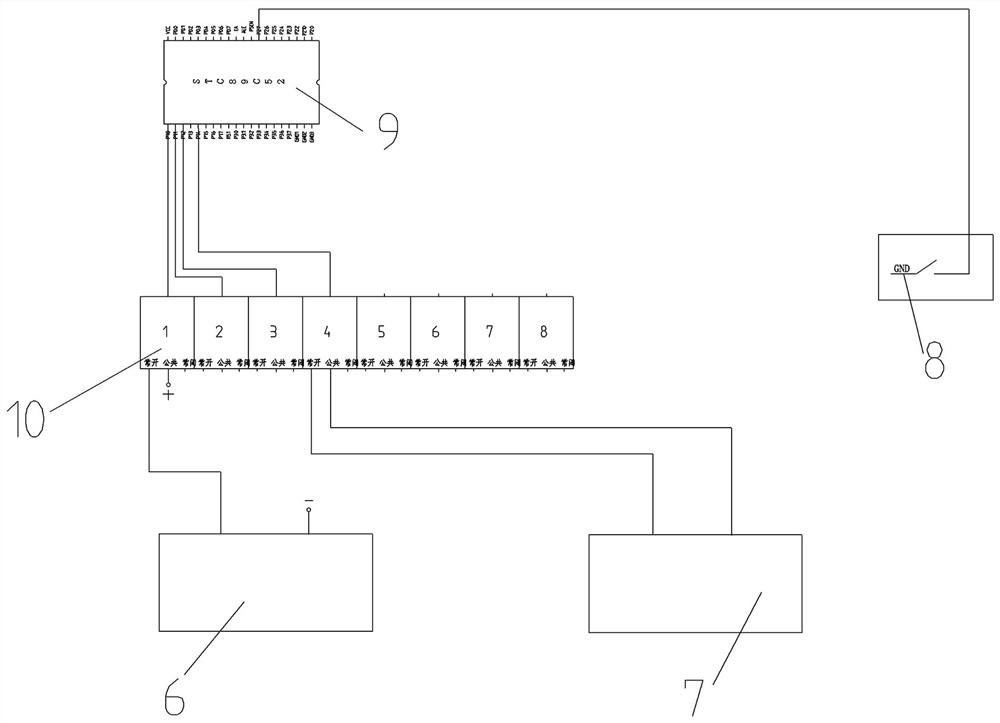

[0084] The main difference between it and Example 1 is that the quenching heating device in Example 1 is modified from the existing quenching equipment. In this embodiment, the quenching heating device is directly integrated on the quenching equipment, that is, the workpiece is directly fixed The unit, button switch and control module are all directly integrated in the quenching equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com