Low-temperature light-weight high-strength porcelainfor daily use and preparation method thereof

A high-strength, lightweight technology, used in applications, household appliances, clay products, etc., can solve the problems of unpredictable color and performance of ceramic products, poor mechanical properties, and easy to be broken.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

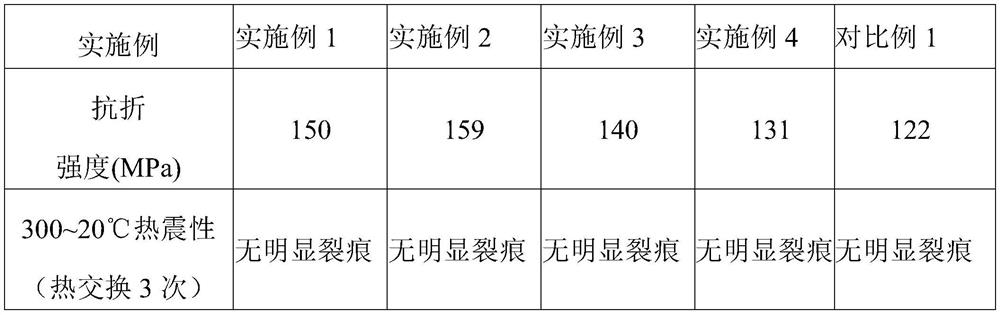

Examples

Embodiment 1

[0019] A kind of low-temperature light-weight high-strength daily-use porcelain, including glaze and enamel, and the enamel includes the following raw materials in parts by weight: 2 parts of pottery clay, 5 parts of bentonite, 5 parts of sand material, and 4 parts of clay; the glaze Including the following raw materials by weight: 10 parts of clam shell powder, 2 parts of bentonite, 10 parts of cordierite, 12 parts of albite; the preparation method of the glaze is: the clam shell powder, cordierite, The albite is put into liquid nitrogen for 20 hours of freezing, then the clam shell powder, cordierite, and albite are taken out and immediately added to a ball mill for 2 hours of dry grinding to obtain a powder, and the powder is mixed with the bentonite in the weight part Stir in a high-speed mixer at a constant temperature of 30°C for 15 minutes at a stirring rate of 500rpm to obtain the mixture, put the mixture into a high-temperature furnace for a heating rate of 8°C / min, ke...

Embodiment 2

[0027] A kind of low-temperature light-weight high-strength daily-use porcelain, including glaze and enamel, the enamel includes the following raw materials in parts by weight: 5 parts of pottery clay, 8 parts of bentonite, 8 parts of sand material, and 9 parts of clay; the glaze Including the following raw materials by weight: 15 parts of clam shell powder, 5 parts of bentonite, 12 parts of cordierite, and 22 parts of albite; the preparation method of the glaze is: the clam shell powder, cordierite, The albite is put into liquid nitrogen for 24h freezing, then the clam shell powder, cordierite, and albite are taken out and immediately added to a ball mill for 3h dry grinding to obtain a powder, and the powder is mixed with the bentonite in the weight part Stir in a high-speed mixer at a constant temperature of 35°C for 20min at a stirring rate of 700rpm to obtain a mixture, put the mixture into a high-temperature furnace for a heating rate of 8°C / min, keep it warm for 4 hours ...

Embodiment 3

[0034] A kind of low-temperature light-weight high-strength daily-use porcelain, including glaze and enamel, the enamel includes the following raw materials in parts by weight: 3 parts of pottery clay, 6 parts of bentonite, 6 parts of sand material, and 7 parts of clay; the glaze Including the following raw materials by weight: 12 parts of clam shell powder, 3 parts of bentonite, 11 parts of cordierite, and 18 parts of albite; the preparation method of the glaze is: the clam shell powder, cordierite, The albite is put into liquid nitrogen for 22 hours to freeze, then the clam shell powder, cordierite, and albite are taken out and immediately added to a ball mill for 2.5 hours of dry grinding to obtain a powder, and the powder is mixed with the weight part The bentonite was stirred in a high-speed mixer at a constant temperature of 32°C for 18 minutes at a stirring rate of 600rpm to obtain a mixture, and the mixture was put into a high-temperature furnace for heating at a rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com