Sewage precipitation sludge solidification and drying treatment equipment

A drying treatment and sludge solidification technology, which is applied in sedimentation treatment, dehydration/drying/concentrated sludge treatment, water/sewage multi-stage treatment, etc., can solve the problem of filter blockage and achieve the effect of easy heating and evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

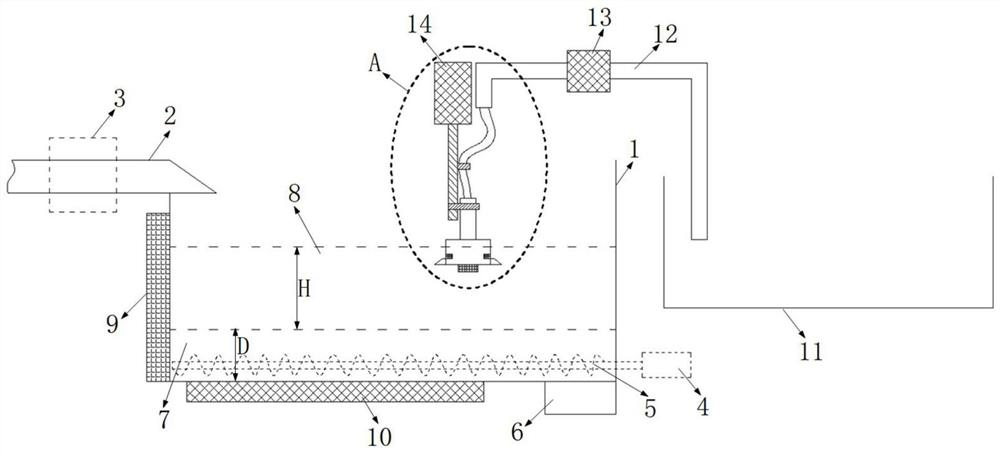

[0049] see figure 1 , figure 2 , The invention relates to a solidification and drying treatment equipment for sewage sedimentation sludge.

[0050] In the sewage sedimentation sludge solidification drying treatment equipment of the present invention: one side of the sludge still water tank 1 is connected with the first sewage water inlet pipe 2, the bottom of the sludge still water tank 1 is provided with a sludge discharge port 6, and the first sewage water A sewage turbidity sensing device 3 is installed on the water inlet pipe 2; a crushing mechanism 5 is provided at the bottom of the sludge still water tank 1, and a bottom side power device 4 for driving the crushing mechanism 5 is provided on the outside of the sludge still water tank 1; The sewage in the static water tank 1 is divided into a bottom sludge layer 7 and an upper static water layer 8 after sedimentation.

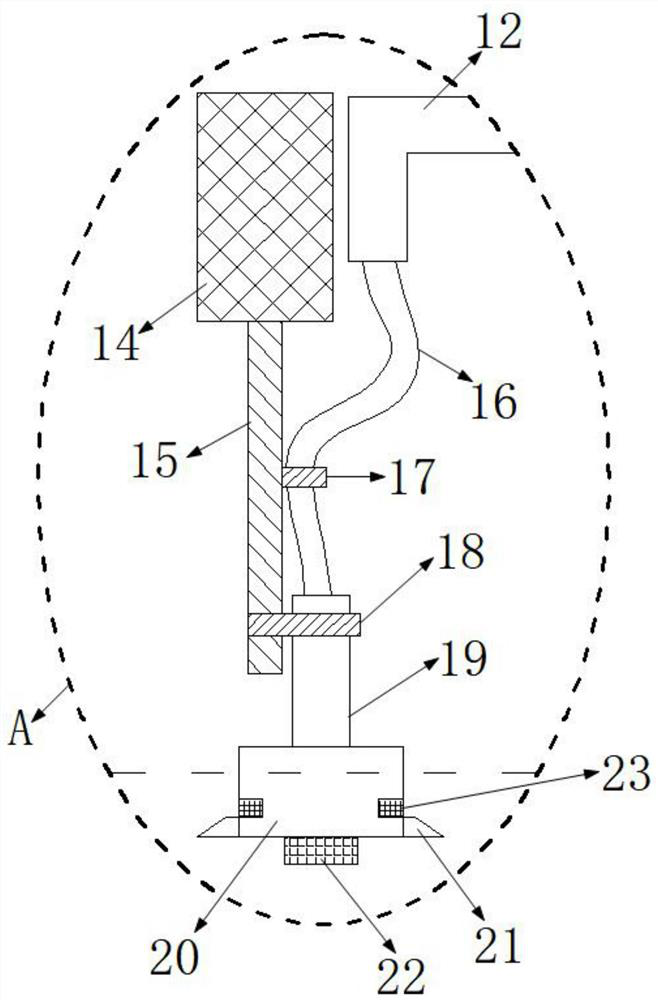

[0051] In the sewage sedimentation sludge solidification and drying treatment equipment of the prese...

Embodiment 2

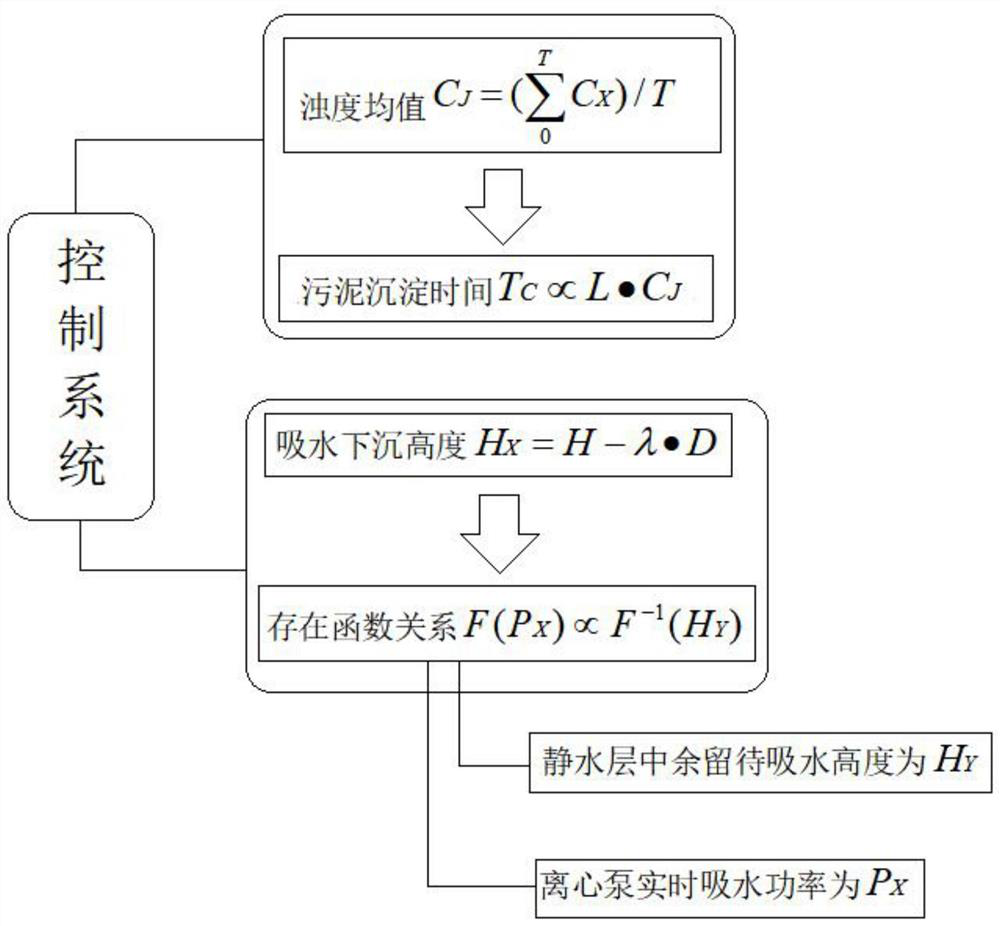

[0055] A control system for sewage sedimentation sludge solidification and drying treatment equipment, the control system includes a main treatment controller, the specific control content is as follows:

[0056] (1) The sewage turbidity sensing device 3 senses and monitors the turbidity of the sewage injected into the sludge still water tank 1 by the first sewage inlet pipe, and analyzes the mean value of the turbidity during the entire injection process.

[0057] (2) After the first sewage inlet pipe 2 is filled, the ultrasonic sensing mechanism 9 detects the total height of the sewage in the sludge still water tank 1, and determines the sludge settling time according to the average turbidity information and the total height information of the sewage.

[0058] (3) After the sludge sedimentation in the sludge still water tank 1 is completed, the ultrasonic sensor mechanism 9 detects the height position state of the sludge layer 7 in the sludge still water tank 1 and the positi...

Embodiment 3

[0081] In the present invention, during the sewage sedimentation process in the sludge still water tank 1, corresponding sedimentation chemical reagents can be added according to the dirty components of the discharged sewage to assist in the sedimentation, so as to improve the sedimentation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com