Constant-torque type automobile steering knuckle arm

An automobile steering knuckle and constant torque technology, which is applied to steering mechanisms, steering rods, vehicle components, etc., can solve problems such as difficult steering and increased steering load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

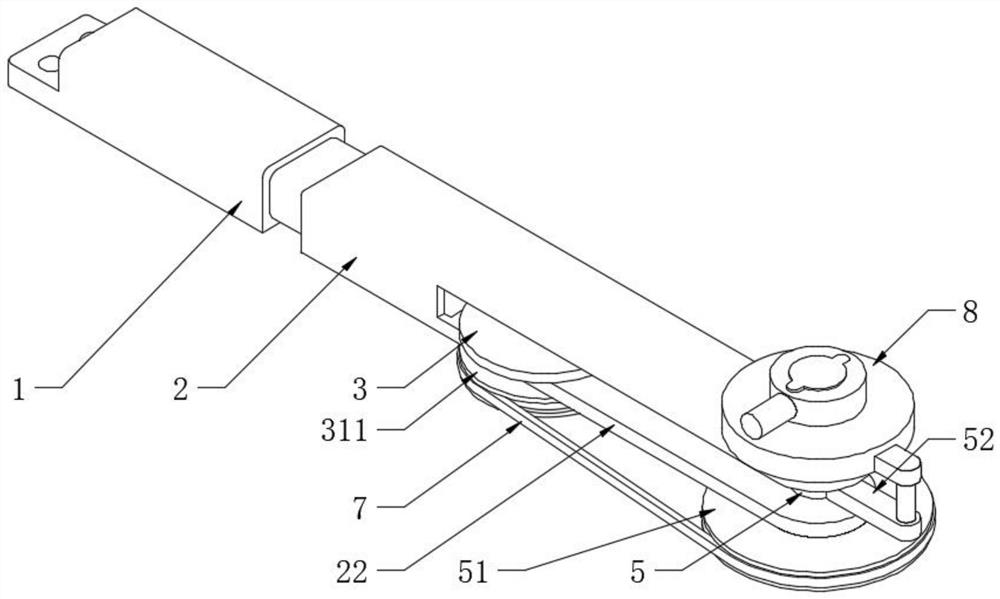

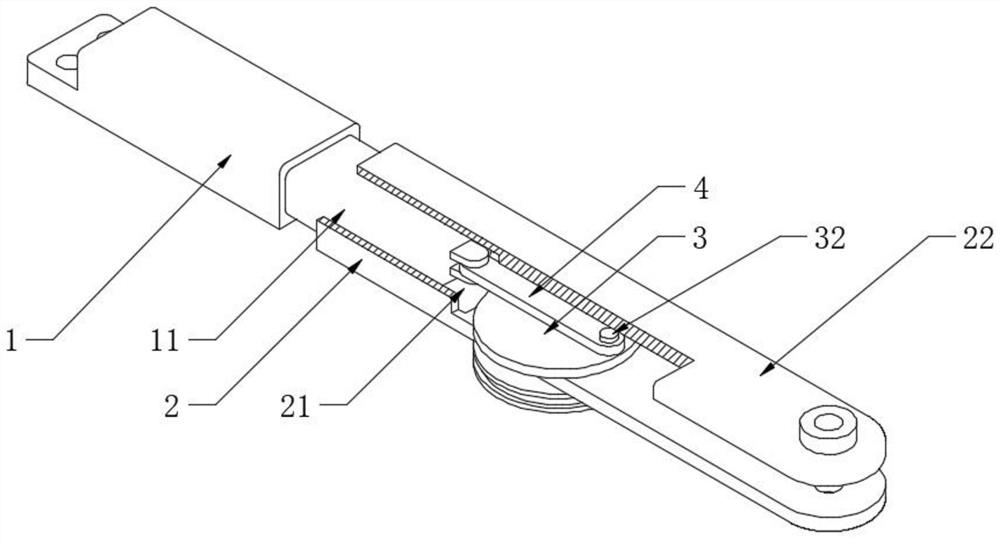

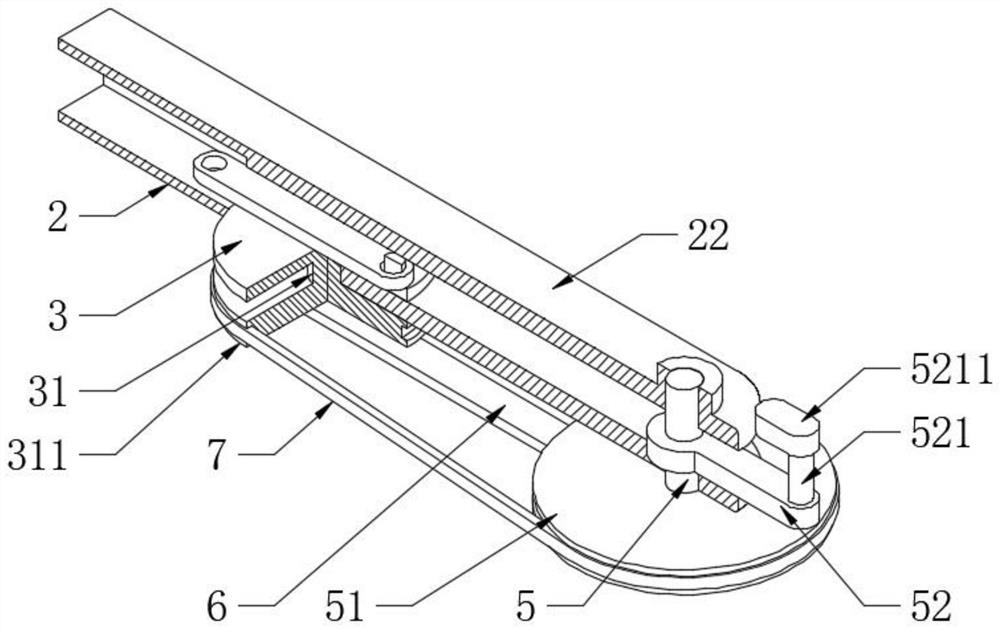

[0030] see Figure 1-4 , a constant torque type automobile steering knuckle arm, including a front arm 1 and a rear arm 2, the forearm 1 is used to be fixedly connected to one of the trapezoidal arms, one end of the forearm 1 is fixedly provided with a guide plate 11, and one end of the rear arm 2 is opened There is a guide hole 21 slidingly matched with the guide plate 11, the forearm 1 and the rear arm 2 are slidingly fitted, the arm plate composed of the two can be extended or shortened, and the other end of the rear arm 2 is fixedly provided with two positioning points distributed parallelly up and down. Plate 22, a transmission turntable 3 is arranged between the two positioning plates 22, and one side of the transmission turntable 3 is fixedly provided with a transmission shaft 31 that is distributed with the same axis and runs through a positioning plate 22 located at the lower part and is rotationally matched. The other side of 3 is fixedly provided with a transmission...

Embodiment 2

[0032] see Figure 5 The difference from Embodiment 1 is that the other end of the drive shaft 5 passes through another positioning plate 22 and is rotatably connected with a concentrically distributed connecting round table 8, the outer wall of the connecting round table 8 is fixedly connected with one end of the docking block 5211, The upper end surface of the round platform 8 is connected with an anti-shock connecting sleeve 9, that is to say, when turning, the steering wheel will swing, and the forearm 1 will swing correspondingly, which will change the angle between the forearm 1 and the steering rod. This swing will change the state that the forearm 1 protrudes relative to the rear arm 2, and the forearm 1 and the rear arm 2 can be locked by setting the anti-shock connecting sleeve 9. Specifically, the upper end surface of the connecting round table 8 is fixedly provided with a coaxial distribution. The shaft 81, the anti-shock connecting sleeve 9 and the matching shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com