High-speed, precise and lightweight isostatic pressing flexible mold locking mechanism and method of injection machine

An injection machine, lightweight technology, applied in the field of static pressure flexible clamping mechanism, can solve the problems of large weight of clamping system, large impact load, large mold inertia, etc., and achieve simple structure, small impact load, and mold inertia. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

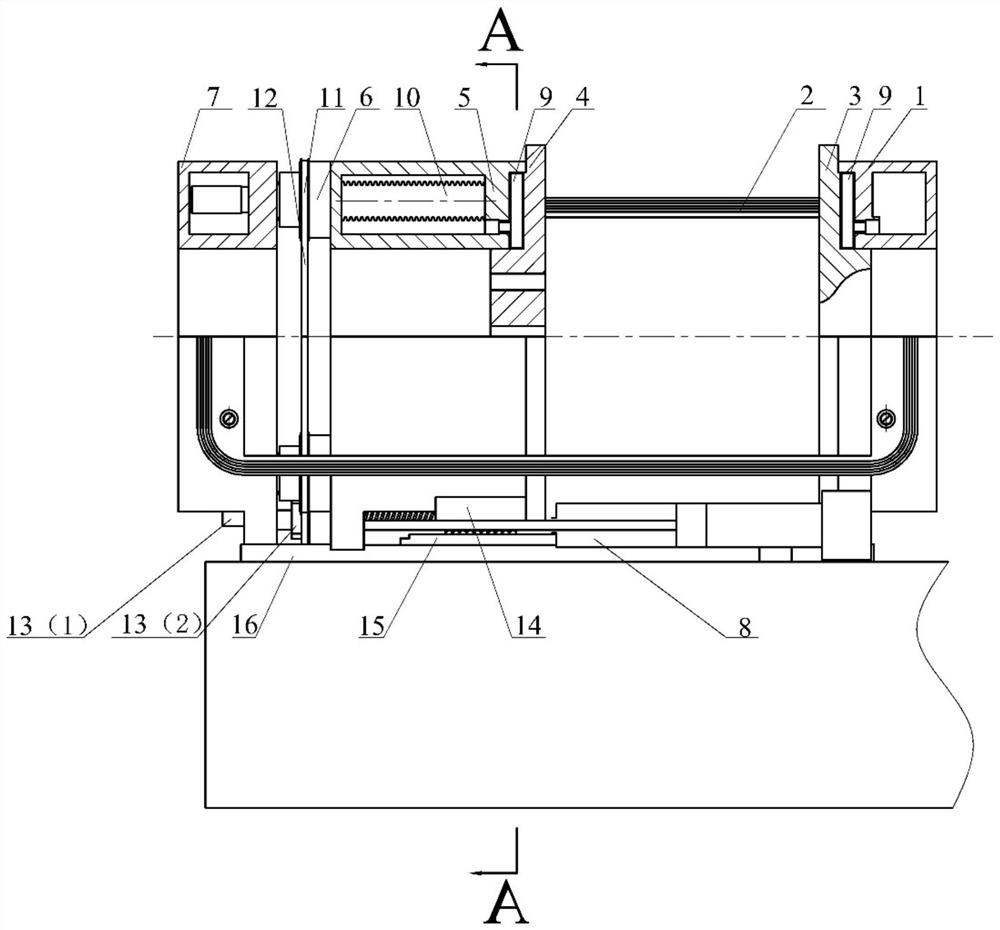

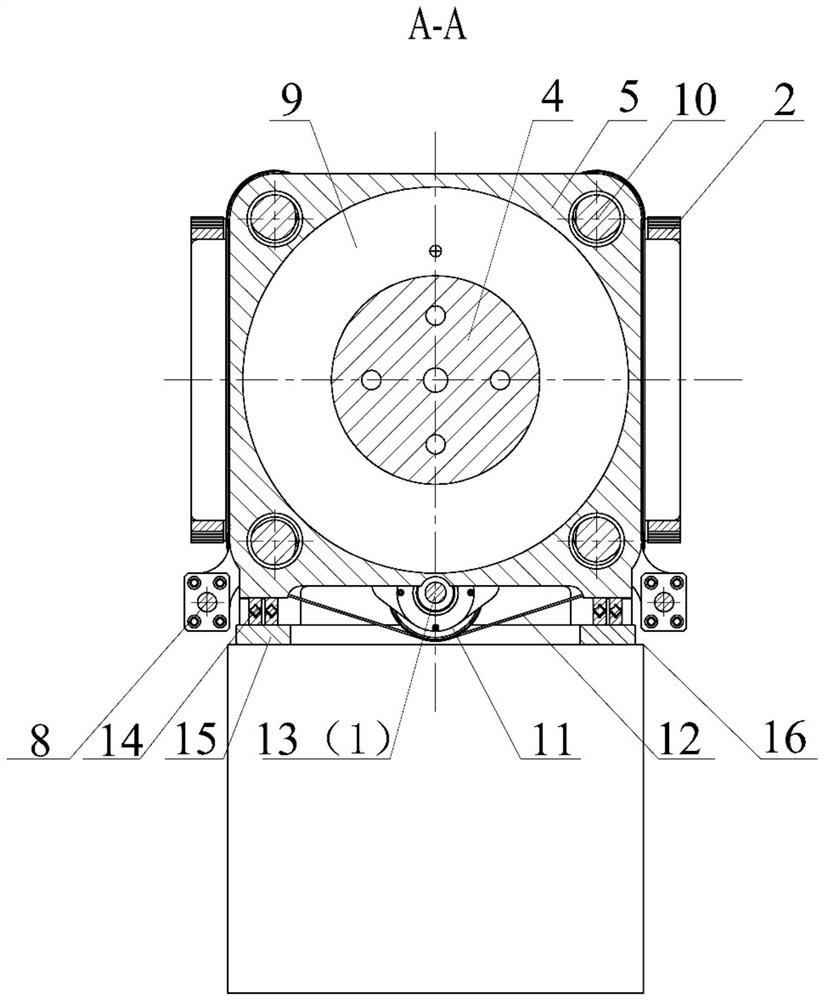

[0034] In this embodiment, a lightweight isostatic flexible mold clamping mechanism for a high-speed precision injection machine, such as Figure 1-3 As shown, it includes a fixed mold support plate 3, a fixed mold static pressure support seat 1, a movable mold support plate 4, a dynamic mold static pressure support seat 5 and a mold locking positioning seat 7, and the fixed mold support plate and the movable mold support plate are opposite to each other. Set, a liquid-filled capsule 9 is provided between the fixed mold support plate and the fixed mold static pressure support seat, a liquid-filled capsule 9 is provided between the movable mold support plate and the dynamic mold static pressure support seat, and the dynamic mold static pressure support seat Located on the moving assembly, the clamping positioning seat is located outside the static pressure support seat of the dynamic mold, and a synchronous follower device for axial positioning is provided between the static pre...

Embodiment 2

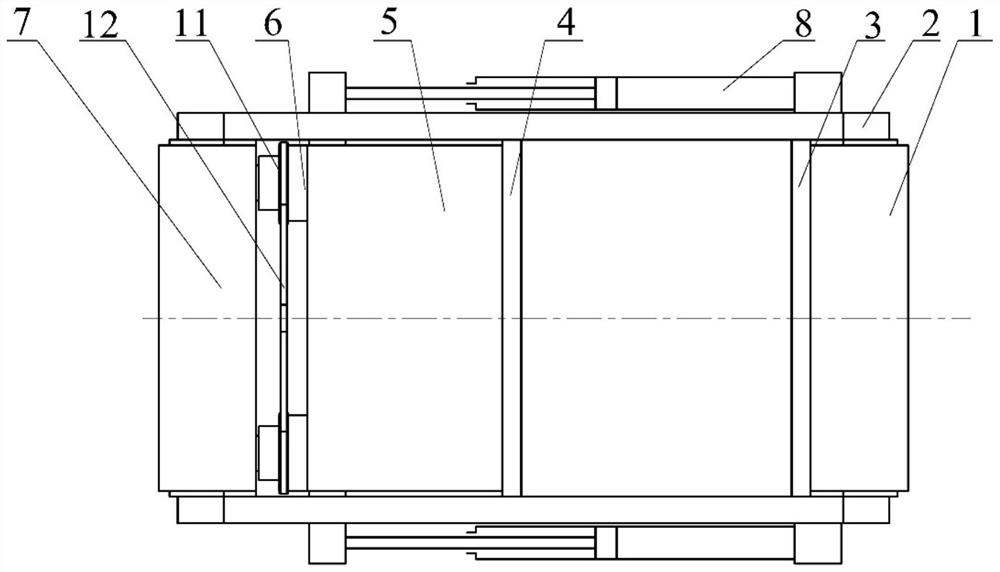

[0049] In this embodiment, a lightweight isostatic flexible mold clamping mechanism for a high-speed precision injection machine, such as Figure 4-6 As shown, the difference from Embodiment 1 is that a brake nut 17 for axial positioning is provided between the static pressure support seat of the dynamic mold and the mold locking positioning seat, and the dynamic mold positioning seat is provided on the mold locking positioning seat. A screw pile, wherein the dynamic mold positioning screw pile passes through the static pressure support seat of the dynamic mold. Among them, there are 4 moving mold positioning screw piles, which are respectively installed at the four corners of the mold locking positioning seat. The brake nut is installed on the static pressure support seat of the dynamic mold, and the brake nut is correspondingly provided with a brake oil cylinder, and the brake nut is driven by the brake oil cylinder to tightly hold the dynamic mold positioning screw pile to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com