Nutritional seasoning sauce and preparation method thereof

A seasoning sauce and nutritional technology, which is applied in the field of sauce product processing, can solve the problems of not being able to supplement vitamins well, and achieve the effects of improving taste and flavor, comprehensive vitamin supplementation, and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The preparation of embodiment 1 chickpea natto

[0052] Soak the commercially available chickpeas purchased from Xinjiang with clean water for 12-24 hours, drain the water, sterilize in a sterilizing pot at 125°C for 20-30 minutes, and inoculate 15% bacterial concentration to 1×10 after cooling. 9 CFU / mL order of Bacillus natto bacteria liquid, cultivated at 38°C, fermented for 12 hours and stirred once, and the fermentation culture was completed after 24-26 hours. After the fermentation, the chickpea and natto had a silky and bean aroma, stirred and smashed into a paste shape, sterilized in a 121°C autoclave for 20-30 minutes, and set aside. After testing, the content of vitamin K2 (MK-7) in the prepared chickpeas natto is 920-1200 μg / g.

Embodiment 2

[0053] The preparation of embodiment 2 yeast extract, Maillard reaction type yeast extract

[0054] Preparation of yeast extract: Pass beer waste yeast through a 100-mesh sieve, add 5% sodium bicarbonate to debitterize, wash with water for 2 to 3 times, add 2% saline and treat at 40-60°C for 2 to 4 hours to make the yeast spontaneously Dissolve, then homogeneously break the wall at 80-140Mpa high pressure, cycle 2-4 times, then add the same amount of neutral protease and flavor protease for enzymolysis treatment for 4-6 hours, and obtain the yeast slime treated by enzymatic hydrolysis of the broken wall. The yeast mud is concentrated in vacuum until the water content is ≤30%, and the yeast extract is obtained.

[0055] Preparation of Maillard reaction type yeast extract: add 2 parts of glucose, 2 parts of xylose, 1 part of lysine, 1 part of hydrochloride and 1 part of glycine, adjust the pH to 6.0-6.5, and react in a reaction kettle at 100-120° C. for 30-40 minutes to obtain ...

Embodiment 3

[0056] The preparation of embodiment 3 nutritional biological sauce formula I

[0057] 100 parts of yeast extract, 10 parts of Maillard reaction type yeast extract prepared in Example 2, 10 parts of chickpea natto prepared in Example 1, 10 parts of clam extract, 10 parts of scallop extract, pine needles 10 parts of extract, 5 parts of salmon hydrolyzate, 5 parts of cod liver, 5 parts of black garlic, 5 parts of onion, 5 parts of celery powder, emulsified and mixed at 80-90 °C with high-speed vacuum homogeneous stirring, rotating speed 3000-4000rpm, stirring for 10 ~20min, canned and sterilized, the water content of the product is 35%.

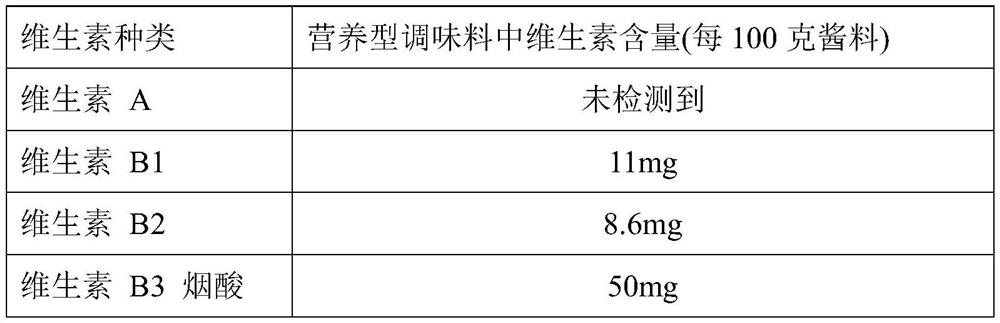

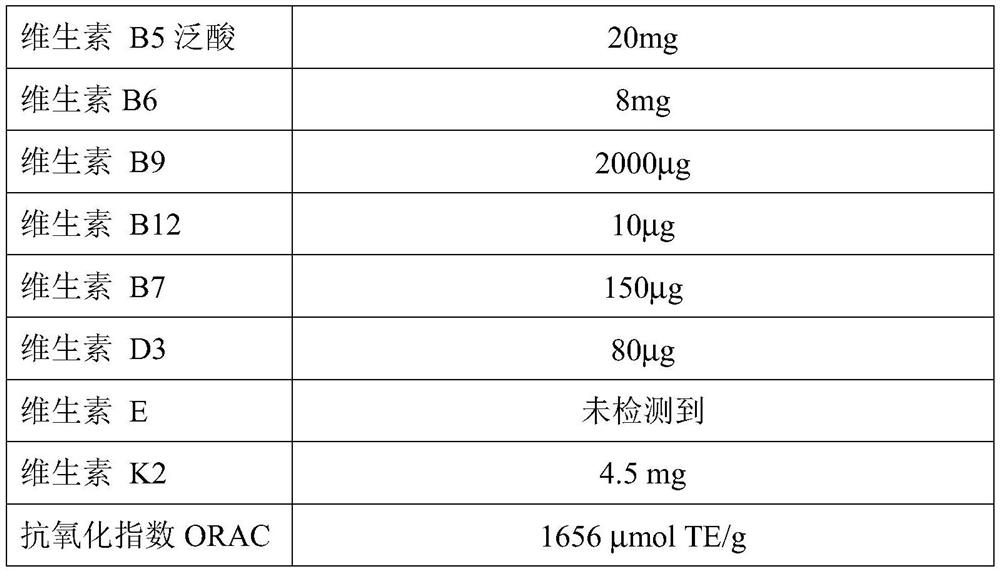

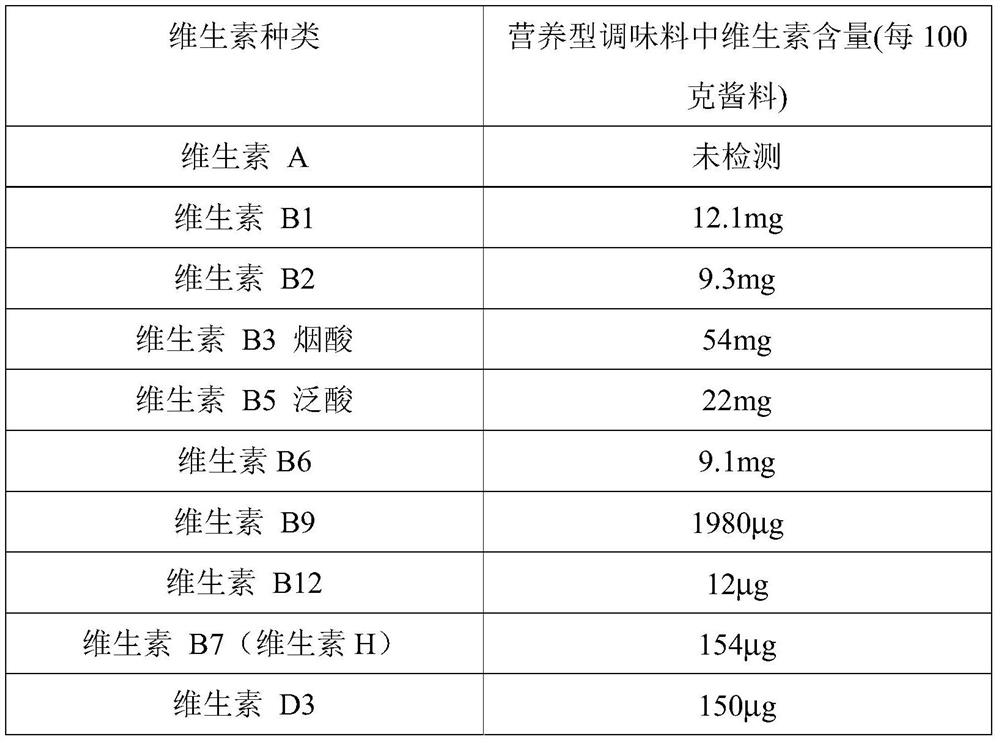

[0058] Table 1 Vitamin and antioxidant index in nutritional seasoning sauce (calculated per 100 grams of sauce)

[0059]

[0060]

[0061] The above test results show that eating 2-3 spoons (5 grams per spoon) of bio-sauce can basically meet the human body's demand for B vitamins.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com