Aquatic weed harvesting mechanism and harvesting ship

A technology of aquatic plants and direction-changing mechanisms, which is applied in the direction of harvesters, cutters, agricultural machinery and implements, etc. It can solve the problems of not installing a compression collection device, difficulty in cutting weeds and eradicating roots, and shortening the interval between weeding. It achieves compact structure, The effect of high working stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

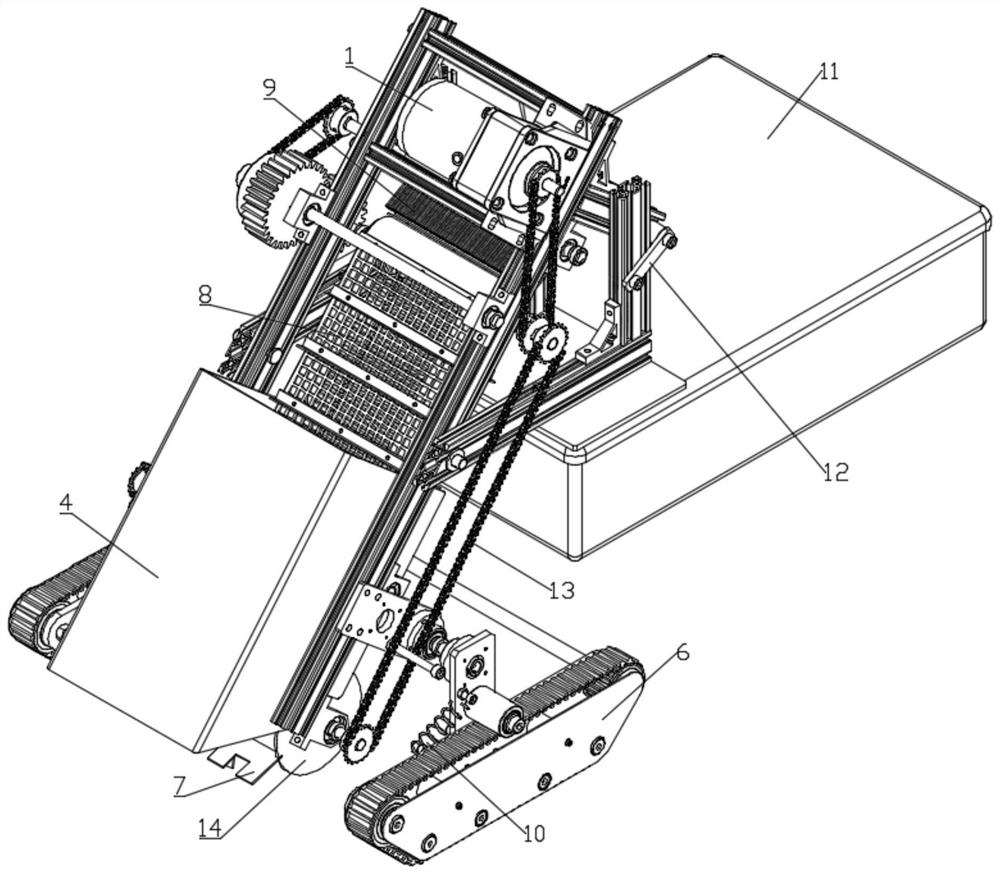

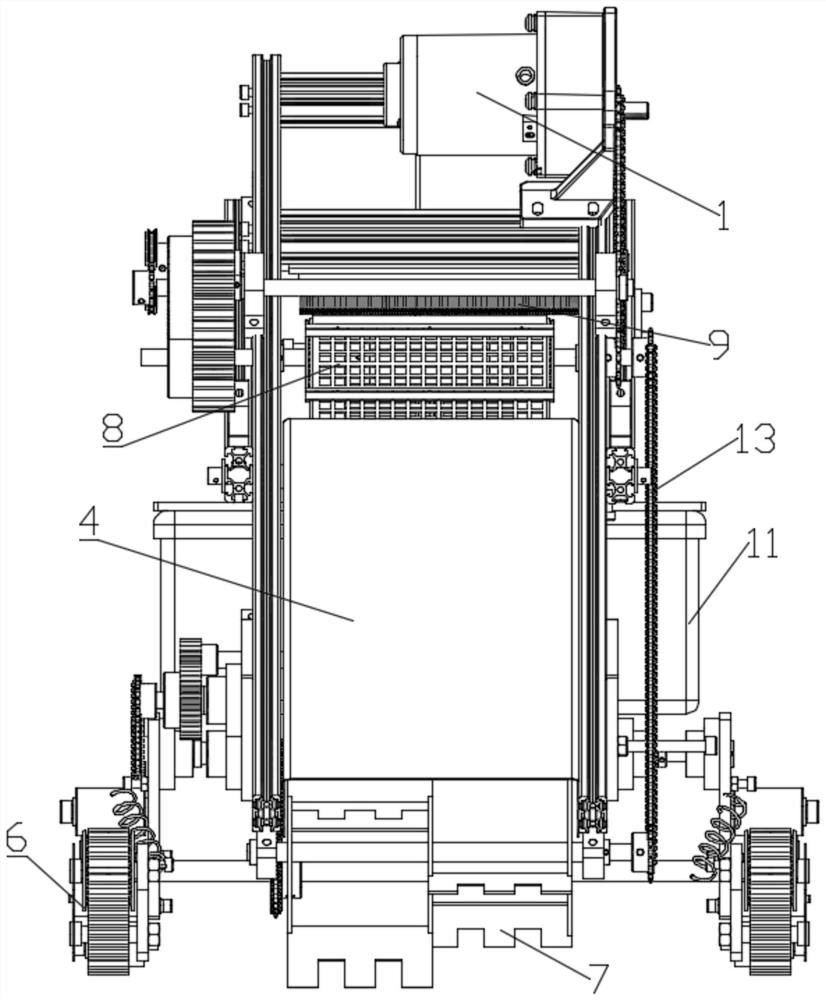

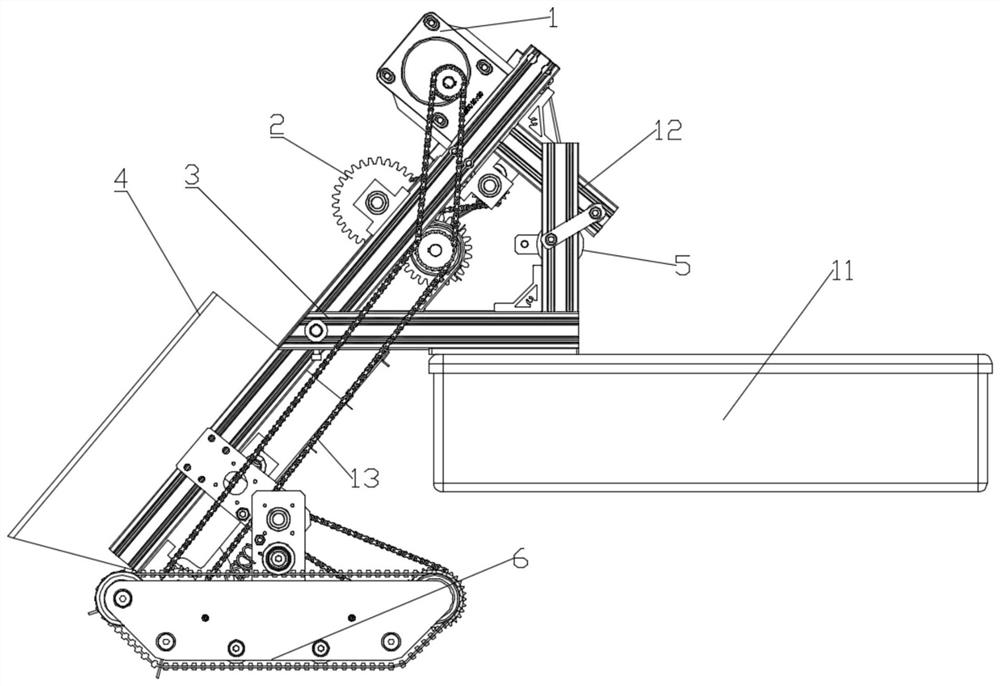

[0026] A waterweed harvesting mechanism, comprising a frame 3 and a carrier 11, the carrier 11 is fixed behind the frame 3, a motor 1, a speed change and direction change mechanism 2, a conveyor belt 8 and a symmetrically arranged rotary tillage assembly are installed on the frame 3, The output end of the motor 1 is connected with the transmission chain 13, and the output end of the motor 1 is also connected with the speed change and direction change mechanism 2 through the power output shaft. 7. The transmission chain 13 is connected with the flat wheel 14 and the transmission chain 13 is connected with the conveyor belt 8 through the conveying roller assembly. On the side, the motor 1 works to drive the variable speed and direction changing mechanism 2 to work, and the speed changing and direction changing mechanism 2 drives the traveling mechanism 6 to walk on the bottom of the river to reduce the contact pressure. When working, the grass-guiding rake plow 7 combs the aquat...

Embodiment 2

[0032] A waterweed harvesting mechanism, comprising a frame 3 and a carrier 11, the carrier 11 is fixed behind the frame 3, a motor 1, a speed change and direction change mechanism 2, a conveyor belt 8 and a symmetrically arranged rotary tillage assembly are installed on the frame 3, The output end of the motor 1 is connected with the transmission chain 13, and the output end of the motor 1 is also connected with the speed change and direction change mechanism 2 through the power output shaft. 7. The transmission chain 13 is connected with the flat wheel 14 and the transmission chain 13 is connected with the conveyor belt 8 through the conveying roller assembly. On the side, the motor 1 works to drive the variable speed and direction changing mechanism 2 to work, and the speed changing and direction changing mechanism 2 drives the traveling mechanism 6 to walk on the bottom of the river to reduce the contact pressure. When working, the grass-guiding rake plow 7 combs the aquat...

Embodiment 3

[0037] A harvesting boat includes a hull on which the aquatic grass harvesting mechanism described in the above embodiments is installed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com