lawn weed remover

A technology for removing weeds and weeds, applied in lawn growth, weed elimination equipment, soil preparation machinery, etc., can solve the problems of unfavorable turf plant growth, high labor cost, low efficiency, etc., and achieves favorable growth and high weeding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

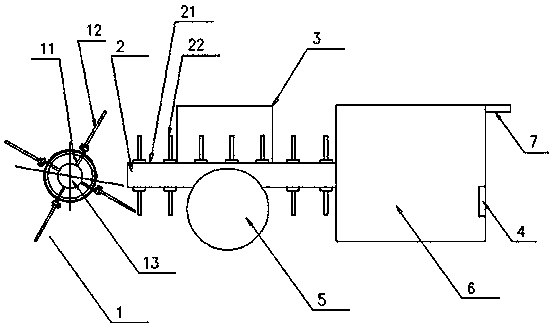

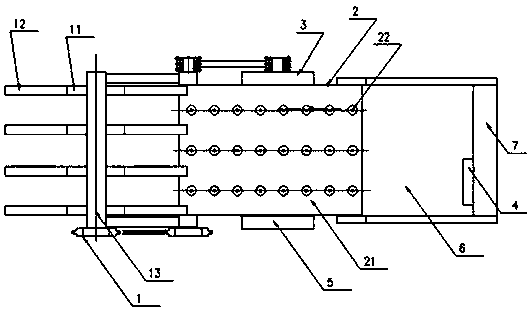

[0020] Such as figure 1 , 2 As shown, the lawn weed removal machine includes a weeding device 1, a transmission device 2, a power unit 3, a moving roller 5, and a grass storage box 6, and the power unit 3 drives the weeding device 1 and the transmission device 2 to move, and the grass is stored The box 6 is placed at the tail of the conveyor 2 for storing weeds; the moving roller 5 is placed at the bottom of the conveyor 2 to realize the overall movement of the whole weed removal machine; the weeding device 1 includes elastic gears 13, elastic gears 13 is provided with a weed gripper, and the weed gripper is composed of two parts, the root is a hard iron sheet 11, and the end is an elastic steel sheet 12, and the hard iron sheet is movably connected with the elastic steel sheet. The elastic steel sheet can be bent. This structural mode is mainly to realize the movable function of each joint similar to the hand, so as to grasp the weeds and realize the uprooting of the weeds....

Embodiment 2

[0022] Such as figure 1 , 2 As shown, the lawn weed removal machine includes a weeding device 1, a transmission device 2, a power unit 3, a moving roller 5, and a grass storage box 6, and the power unit 3 drives the weeding device 1 and the transmission device 2 to move, and the grass is stored The box 6 is placed at the tail of the conveyor 2 for storing weeds; the moving roller 5 is placed at the bottom of the conveyor 2, and its main function is to realize the overall movement of the lawn weed removal device; the weeding device 1 includes elastic gears 13, The elastic gear 13 is provided with a weed grip, the weed grip consists of two parts, the root is a hard iron sheet 11, and the end is an elastic steel sheet 12, the hard iron sheet is flexibly connected with the elastic steel sheet, The elastic steel sheet can be bent, and this structural mode is mainly to realize the movable function of each joint similar to that of a hand, so as to grasp the weeds and realize the upr...

Embodiment 3

[0034] On the basis of Example 1, the number of hard iron sheets (11) is set to 4 pieces, and the number of elastic steel sheets (12) is adapted to the number of hard iron sheets (11).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com