Qualitative detection method for vulcanization accelerator in rubber and application of qualitative detection method

A technology of vulcanization accelerator and qualitative detection, which is applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of difficult qualitative detection of vulcanization accelerators, inability to qualitatively detect vulcanization accelerators, etc., and achieves improved qualitative accuracy and high grinding efficiency. , The effect of high qualitative detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1 of the present invention provides a kind of qualitative detection method of vulcanization accelerator in rubber, specifically as follows:

[0055] (1) 3g of mixed rubber is frozen, ground and pulverized for 15s;

[0056] (2) Use 10 mL of organic solvent to ultrasonically wash the rubber ground and pulverized in step (1) at 35° C. for 3 times, each time for 30 minutes, to obtain an extract;

[0057] (3) The extract is subjected to GC-MS test analysis.

[0058] The organic solvent is methanol and chloroform with a volume ratio of 1:2.

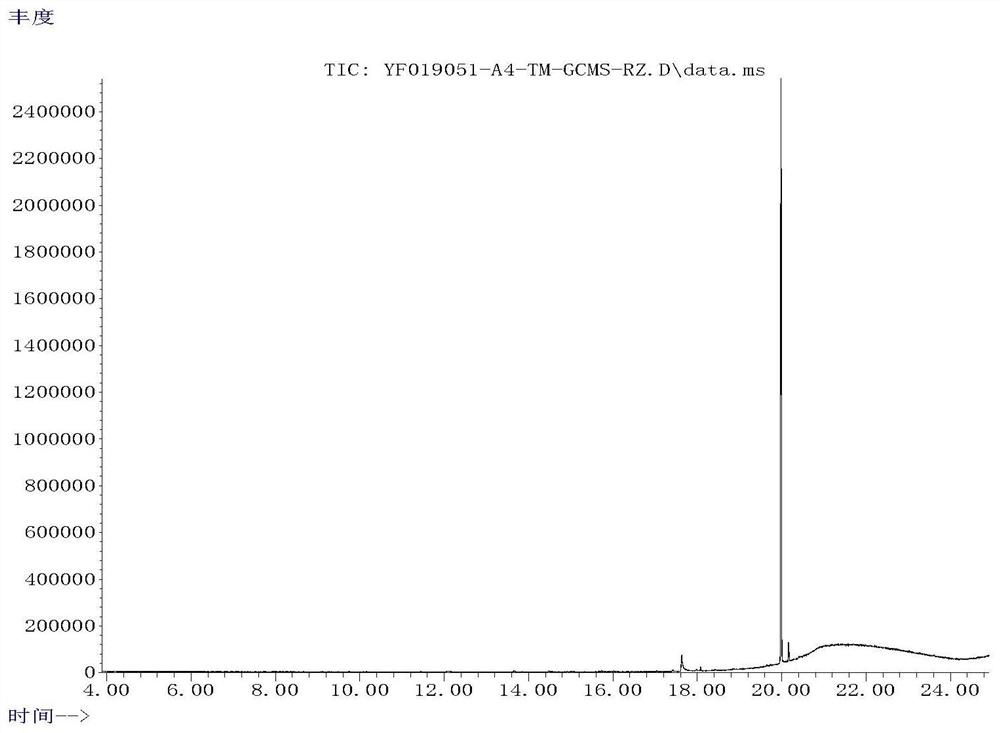

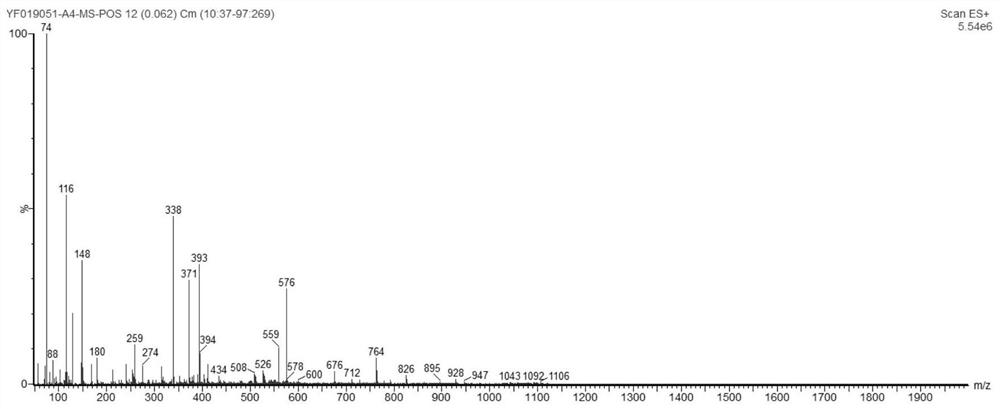

[0059] The resulting GC-MS spectrum is shown in figure 1 , see MS spectrum figure 2 .

[0060] From figure 1 and figure 2 According to the analysis, the vulcanization accelerators in the mixed rubber are 2,2'-dithiodibenzothiazole (DM), tellurium diethyldithiocarbamate (TDEC), tetramethyl Qiumonosulfide Lamb (TMTM), tetramethylthiuram disulfide (TMTD), the accuracy rate reaches 100%.

Embodiment 2

[0062] Embodiment 2 of the present invention provides a kind of qualitative detection method of vulcanization accelerator in rubber, specifically as follows:

[0063] (1) 3g of mixed rubber is frozen, ground and pulverized for 15s;

[0064] (2) Use 20 mL of organic solvent to ultrasonically wash the ground rubber in step (1) at 35° C. for 3 times, each time for 30 minutes, to obtain an extract;

[0065] (3) The extract is subjected to GC-MS test analysis.

[0066] The organic solvent is methanol and chloroform with a volume ratio of 1:1.

[0067] The vulcanization accelerator obtained by GC-MS analysis is consistent with the theoretical value, and the accuracy rate reaches 100%.

Embodiment 3

[0069] Embodiment 3 of the present invention provides a kind of qualitative detection method of vulcanization accelerator in rubber, specifically as follows:

[0070] (1) 3g of mixed rubber is frozen, ground and pulverized for 15s;

[0071] (2) Use 15 mL of organic solvent to ultrasonically wash the ground rubber in step (1) at 35° C. for 3 times, each time for 30 minutes, to obtain an extract;

[0072] (3) The extract is subjected to GC-MS test analysis.

[0073] The organic solvent is methanol and chloroform with a volume ratio of 1:3.

[0074] The vulcanization accelerator obtained by GC-MS analysis is consistent with the theoretical value, and the accuracy rate reaches 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com