A comprehensive recovery system for industrial waste heat and pressure

A technology for recycling system and industrial waste heat, applied in lighting and heating equipment, absorbents/adsorbents, refrigerators, etc. High quality requirements for industrial residual pressure, to achieve the effect of improving work efficiency and waste heat recovery efficiency, improving heat and mass transfer characteristics, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

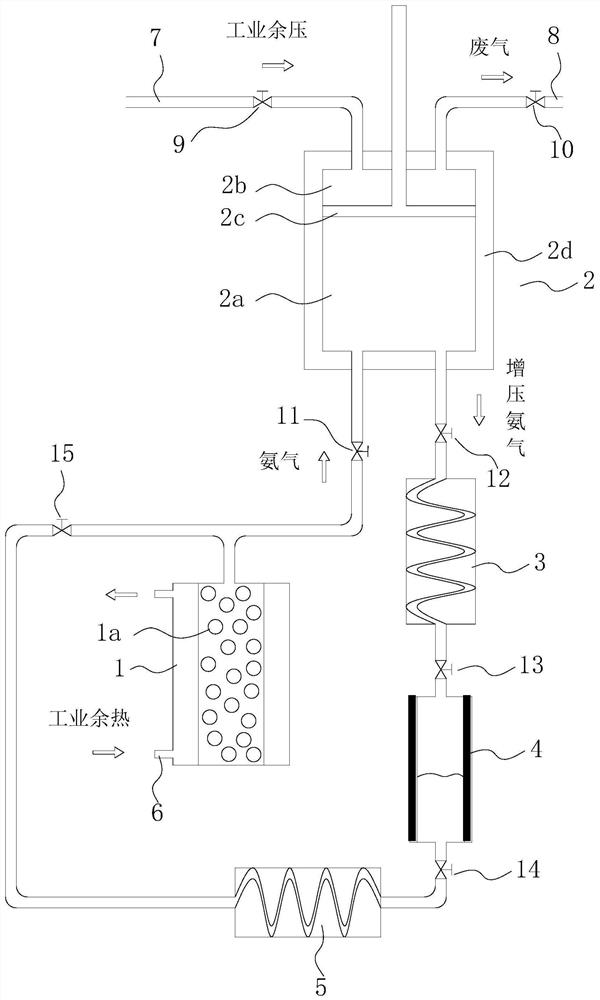

[0035] The present invention will be further described below with reference to the embodiments and the accompanying drawings.

[0036] A comprehensive recovery system for industrial waste heat and pressure, comprising an adsorption refrigeration component, the adsorption refrigeration component is provided with an adsorbate outlet and an adsorbate inlet, the adsorbate outlet is used for desorbed gaseous adsorbate to be exported, and the adsorption The mass inlet is for gaseous adsorbate to enter. The adsorption refrigeration assembly is connected with an adsorbate supercharger 2, and the adsorbate supercharger 2 is provided with a compression chamber 2a, and the compression chamber 2a is provided with a low-pressure air inlet and a high-pressure air outlet; the adsorbate outlet passes through a pipeline The low-pressure air inlet of the compression chamber 2a is connected, and the high-pressure air outlet of the compression chamber 2a is connected to the adsorbate inlet throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com