Cylinder, compressor, refrigeration equipment and production process

A technology for refrigeration equipment and compressors, applied in the field of compressors, which can solve problems such as poor clearance between the sliding vane and the cylinder, affecting the centering clearance of the pump body, and affecting the performance of the compressor, so as to improve the poor clearance, improve work performance, and reduce work. volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

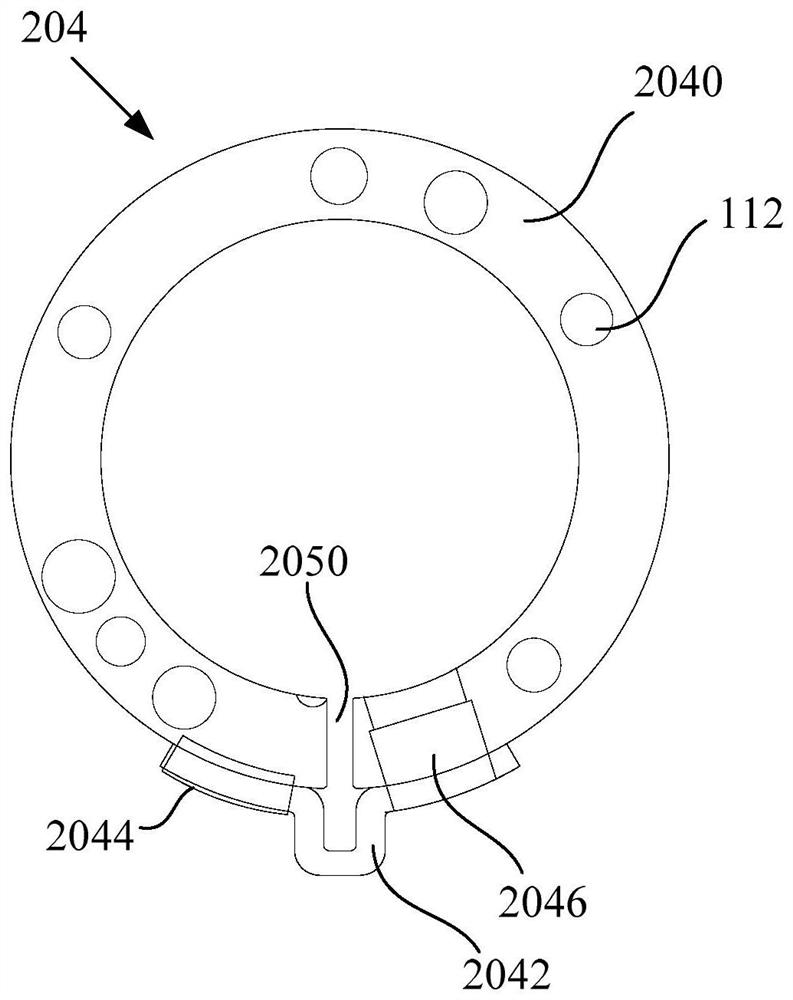

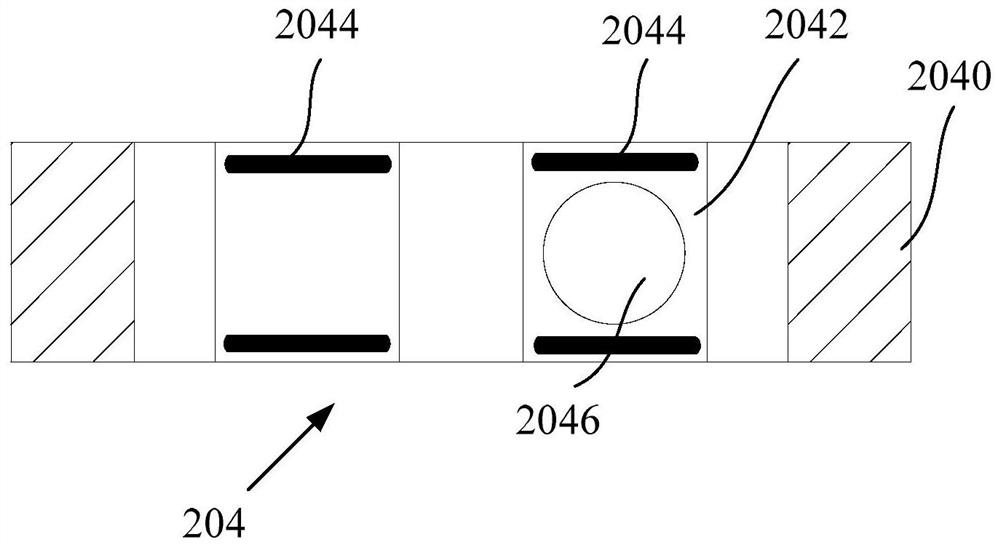

[0030] Such as Figure 1 to Figure 4 As shown, the embodiment according to the first aspect of the present application provides a cylinder 204 . The cylinder 204 includes a body 2040 and an extension 2042 . The extension part 2042 is connected with the main body 2040 . A welding seam 2044 is provided between the protruding portion 2042 and the main body 2040 .

[0031] The cylinder 204 provided according to the embodiment of the present application has a welding seam 2044 between its extension 2042 and the body 2040, that is, the extension 2042 and the body 2040 are connected by welding, and the extension 2042 and the body 2040 can be respectively Manufactured and then joined together by welding. With this welded structure, both the extension part 2042 and the body 2040 can be made of steel. Compared with casting products, the strength of the material of the cylinder 204 formed by welding steel has been improved, and the strength and rigidity of the cylinder 204 have been ...

Embodiment 2

[0033] Another embodiment according to the first aspect of the present application provides a cylinder 204 . The cylinder 204 includes a body 2040 and an extension 2042 . The extension part 2042 is connected with the main body 2040 . A laser welding seam 2044 is provided between the protruding portion 2042 and the body 2040 .

[0034] In the cylinder 204 provided according to the embodiment of the present application, a laser welding seam 2044 is provided between the extension part 2042 and the body 2040, that is, the extension part 2042 and the body 2040 are connected by laser welding. Using laser welding has many advantages such as good processing stability, high processing efficiency, low machine loss, wide processing range, and low processing condition requirements, which is conducive to improving the convenience and processing efficiency of cylinder 204 processing and reducing processing costs.

[0035] Specifically, during laser welding, the amount of heat input can be...

Embodiment 3

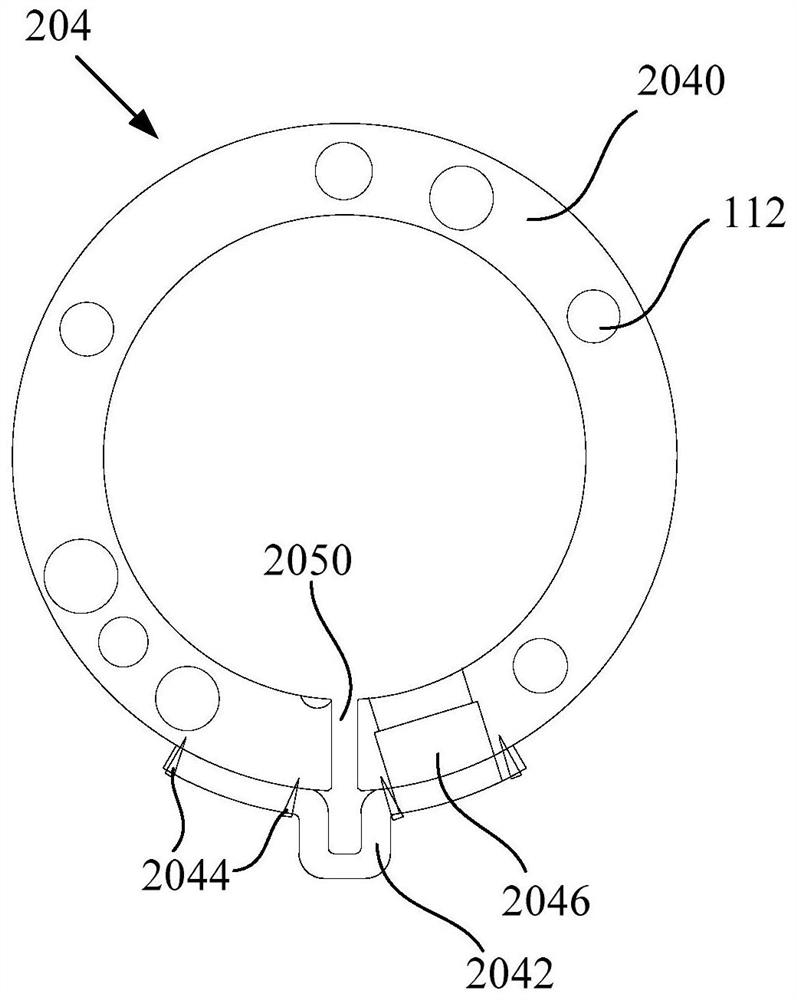

[0044] Another embodiment according to the first aspect of the present application provides a cylinder 204 . The cylinder 204 includes a body 2040 and an extension 2042 . The extension part 2042 is connected with the main body 2040 . A laser welding seam 2044 is provided between the protruding portion 2042 and the body 2040 . Such as image 3 and Figure 4 As shown, the weld 2044 is arranged along the axial direction of the cylinder 204; and / or as figure 1 and figure 2 As shown, the weld 2044 is disposed along the circumference of the cylinder 204 .

[0045] In the cylinder 204 provided according to the embodiment of the present application, a laser welding seam 2044 is provided between the extension part 2042 and the body 2040, that is, the extension part 2042 and the body 2040 are connected by laser welding. Using laser welding has many advantages such as good processing stability, high processing efficiency, low machine loss, wide processing range, and low processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com