Engine integrated double-inlet double-outlet three-stage filtering air inlet system and engine

A double-in, double-out, three-stage filtration technology, applied in engine components, machines/engines, charging systems, etc., can solve the problem of not meeting the intake flow requirements of high-power, large-flow engines, and the oil-bath air filter. Arbitrary selection, can not meet the space installation requirements of the vehicle and other problems, to achieve the effect of compact structure, simple structure, low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

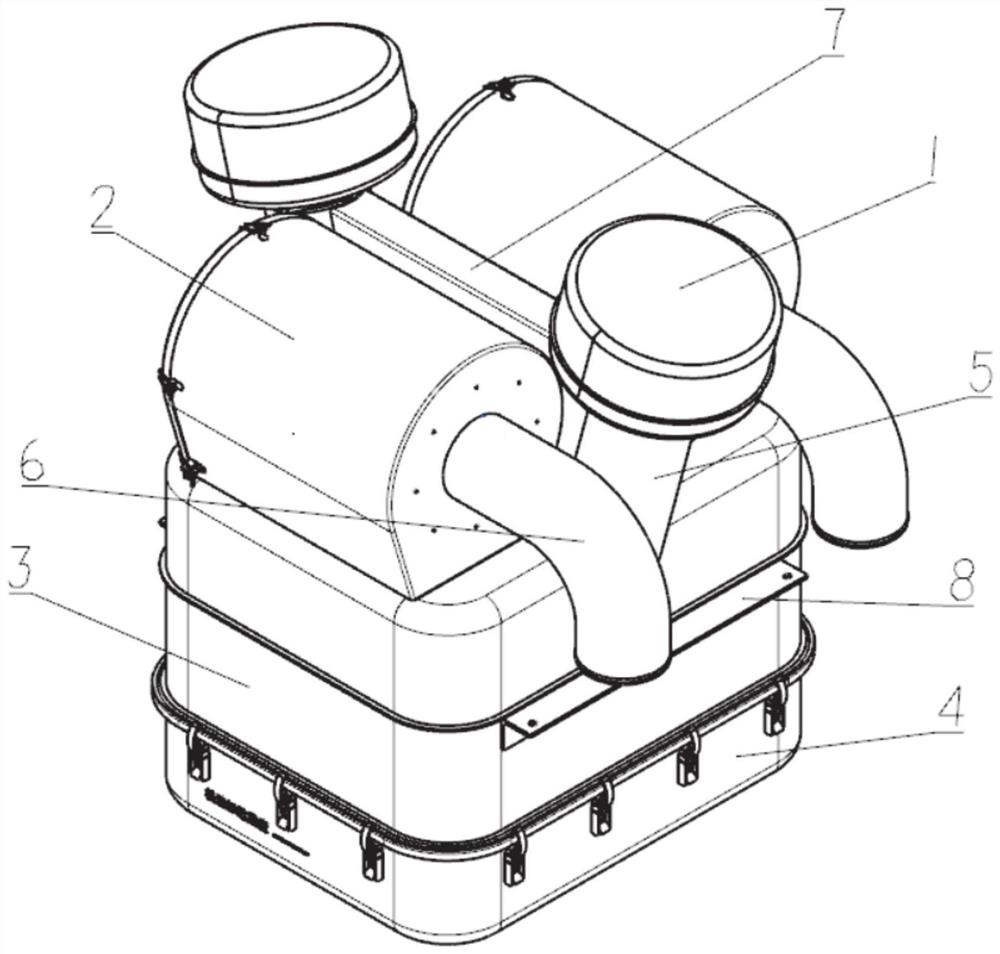

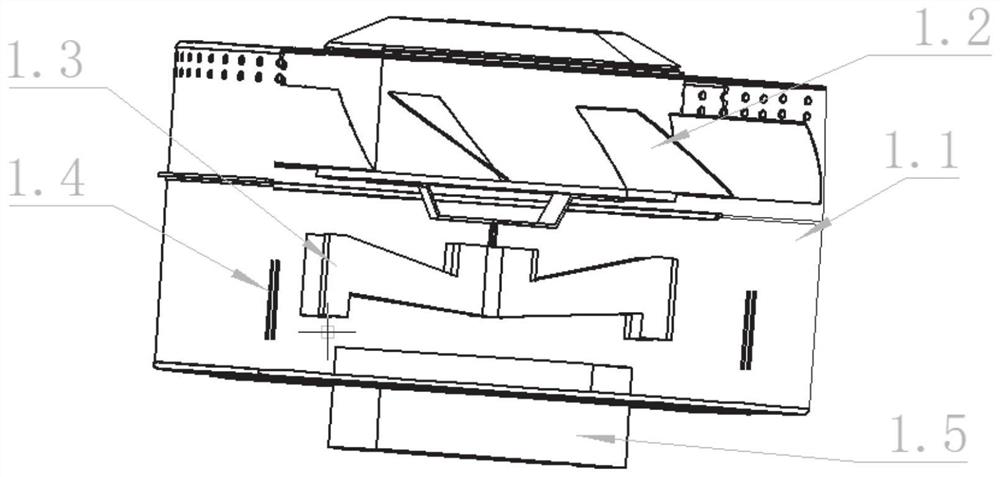

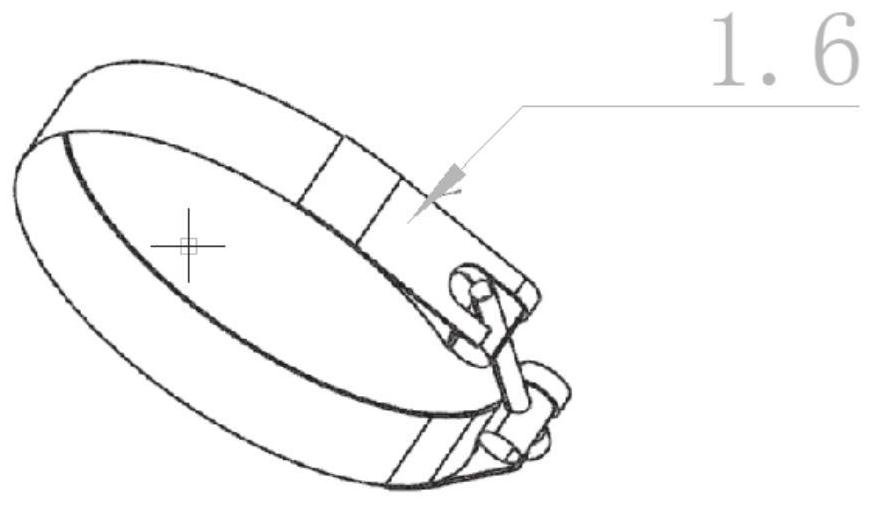

[0032] Such as Figure 1-Figure 3 As shown, this embodiment provides an engine-integrated double-inlet and double-outlet three-stage filter air intake system, including an oil-bath coarse filter, two centrifugal pre-filters and two paper-type fine filters, and the oil-bath coarse filter The two air inlets of the filter are communicated with the air outlets of different centrifugal pre-filters, and the two air outlets of the oil-bath coarse filter are communicated with the air inlets of different paper-type fine filters. The oil-bath coarse filter includes a The upper shell and the lower shell are disassembled and connected, and the upper shell and the lower shell can be enclosed to form an oil bath space. The oil bath space is equipped with a filter liner, and the filter liner is equipped with a coarse filter and a lower filter. The upper filter screen of the coarse filter is installed above the lower filter screen of the coarse filter, and the upper filter screen of the coars...

Embodiment 2

[0048] This embodiment provides an engine that utilizes the engine-integrated double-inlet and double-outlet three-stage filter intake system described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com