Mounting and connecting fitting for fabricated building

A technology for connecting accessories and assembly, applied in the direction of construction and building structure, can solve the problems of difficult assembly, increase the difficulty of assembly, low work efficiency, etc., to reduce the difficulty of assembly, strengthen the support function, and reduce labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

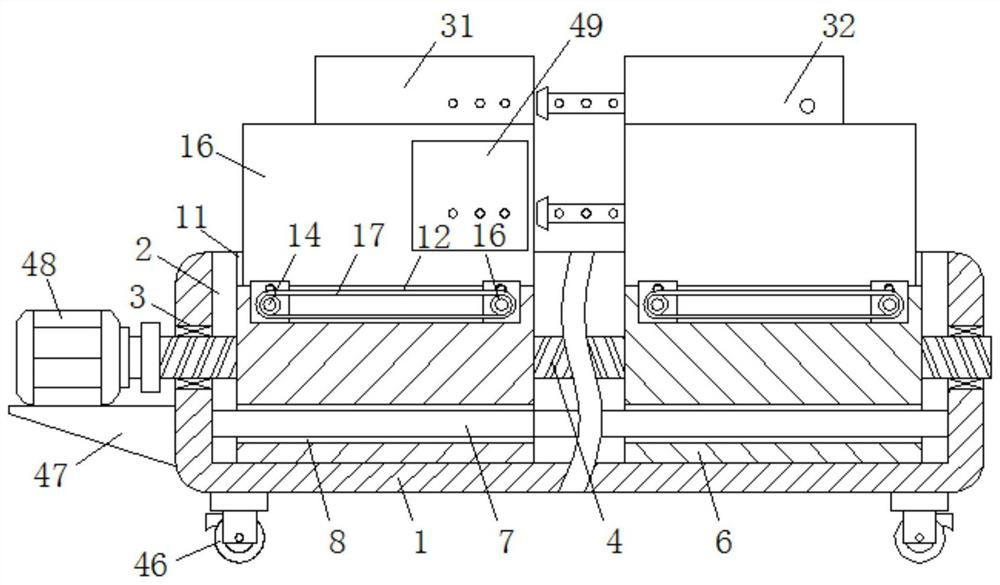

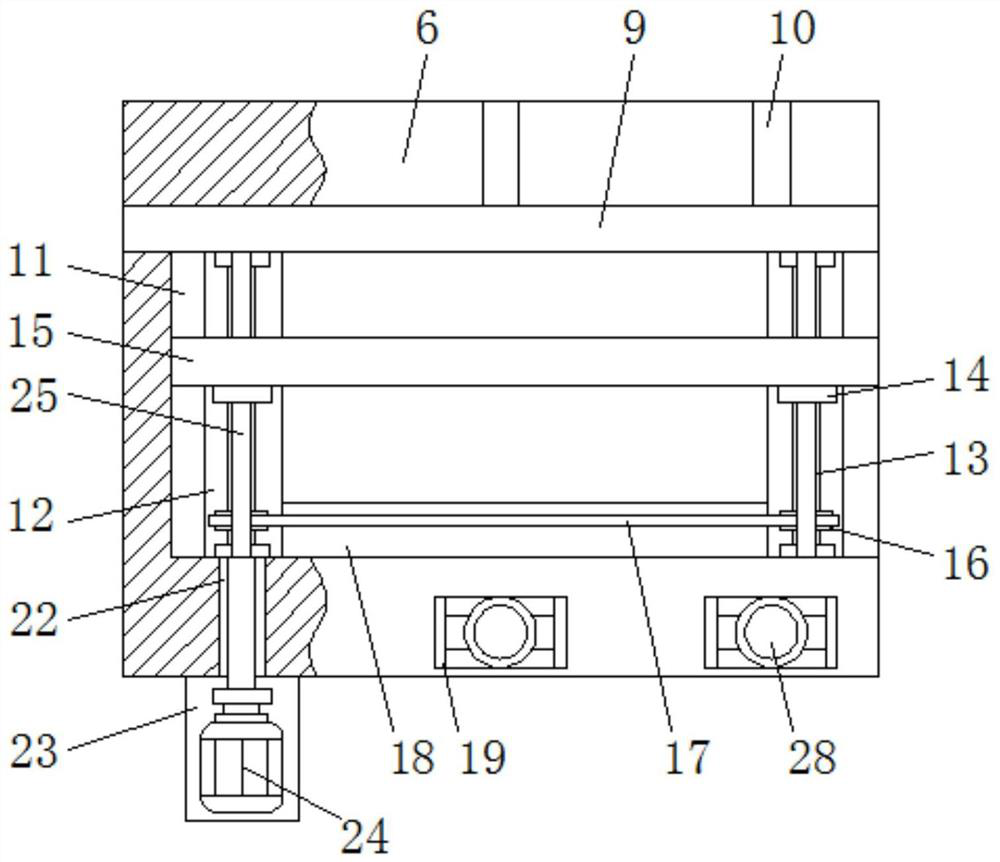

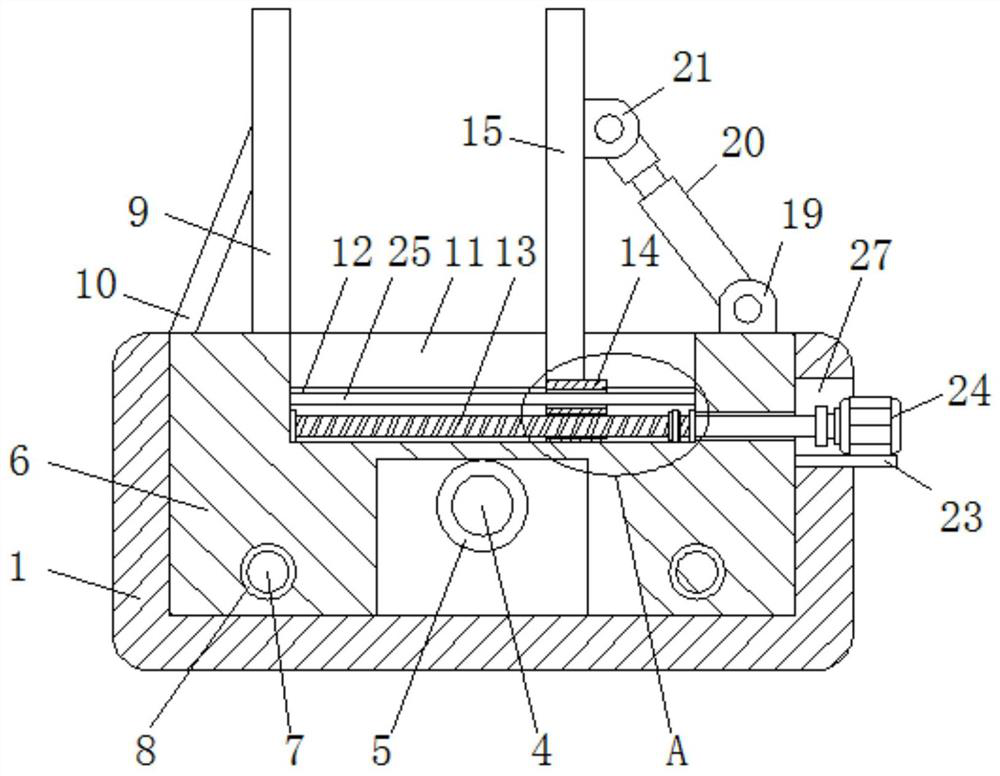

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0032] refer to Figure 1-9 , an installation connection fitting for a prefabricated building, comprising a base 1, a first wall panel 31 and a second wall panel 32, the four corners of the lower end of the base 1 are respectively fixedly connected with casters 46, and the casters 46 are brake wheels, The setting of caster 46 has enhanced the moving ability of device, is convenient to adjust the position of device, facilitates the carrying out of assembly work, and caster 46 can brake lock, has guaranteed the stability when device works.

[0033]The left side of the second wallboard 32 is symmetrically fixedly connected to the insertion rod 33, and the right side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com