Cooking device for vinegar processing

A cooking device and vinegar technology, which are applied in the field of vinegar processing, can solve the problems of inability to realize the inversion of raw materials, waste of energy, and inability to directly utilize the heat of boiling water, etc., and achieve the effects of ensuring cooking quality, uniform heating, and uniform heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

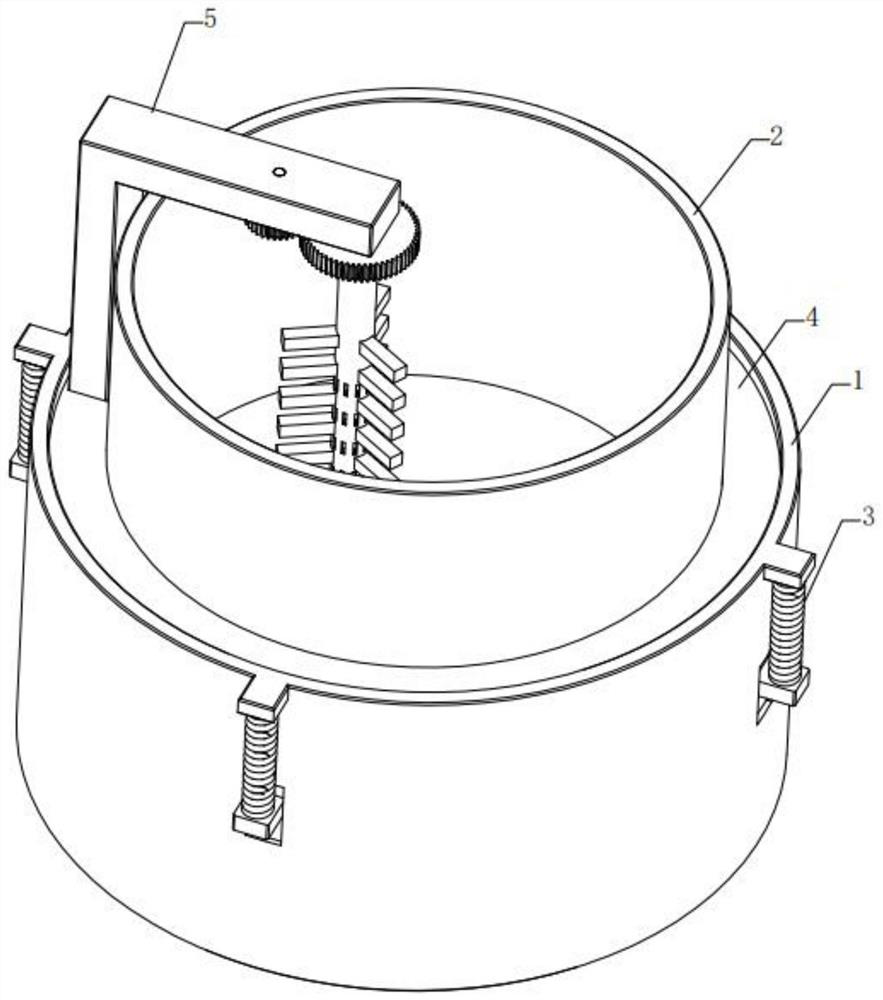

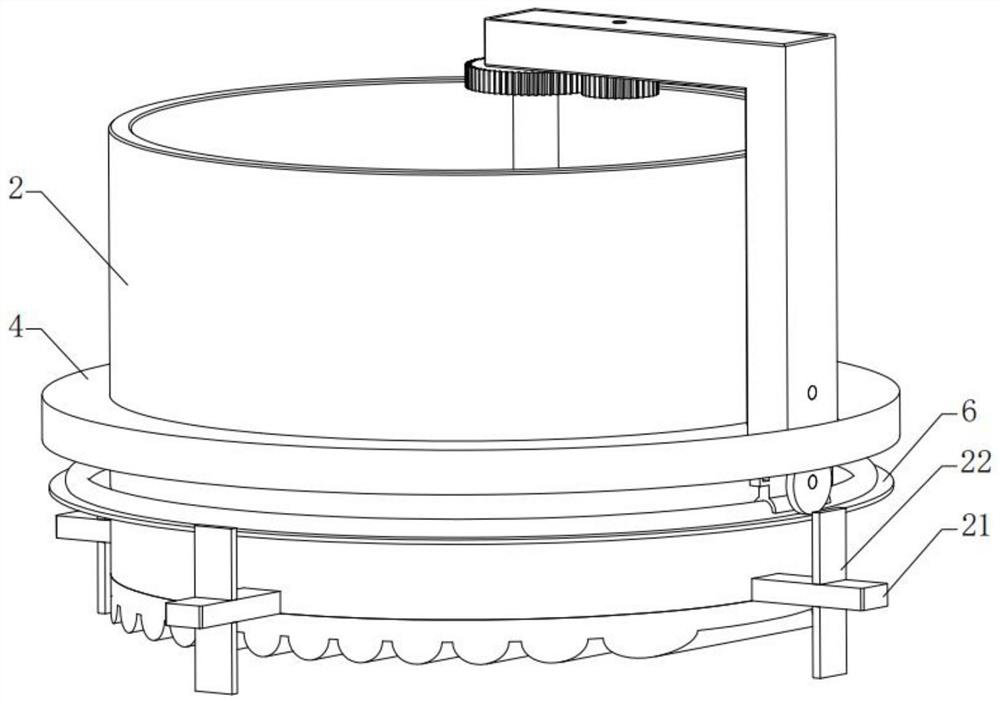

[0028] see Figure 1 to Figure 7 , the present invention provides a technical solution:

[0029] A cooking device for vinegar processing, comprising a heating bucket 1, a cooking bucket 2, a spring 3, an annular sealing plate 4, an air guide pipe 5, an annular guide rail 6, an impeller 7, a walking frame 8 and a stirring shaft 9, wherein :

[0030] The cooking bucket 2 is installed in the heating bucket 1 through the spring 3 and is located at the center of the heating bucket 1, wherein the cylindrical surface of the cooking bucket 2 is provided with a support plate 21, and the support plate 21 runs through the heating bucket 1 and is vertically arranged. The through groove, and then the cooking bucket 2 can move up and down along the vertically arranged through groove, and the spring 3 is connected with the support plate 21 and the outer cylindrical surface of the heating bucket 1, and the upper and lower ends of the support plate 21 are respectively provided with baffles 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com