Clamping mechanism for full-automatic internal polishing machine

A clamping mechanism and internal polishing technology, which is applied to surface polishing machine tools, machine tools suitable for grinding the edge of workpieces, and parts of grinding machine tools. and other issues, to achieve a high degree of automation, reduce the labor intensity of workers, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

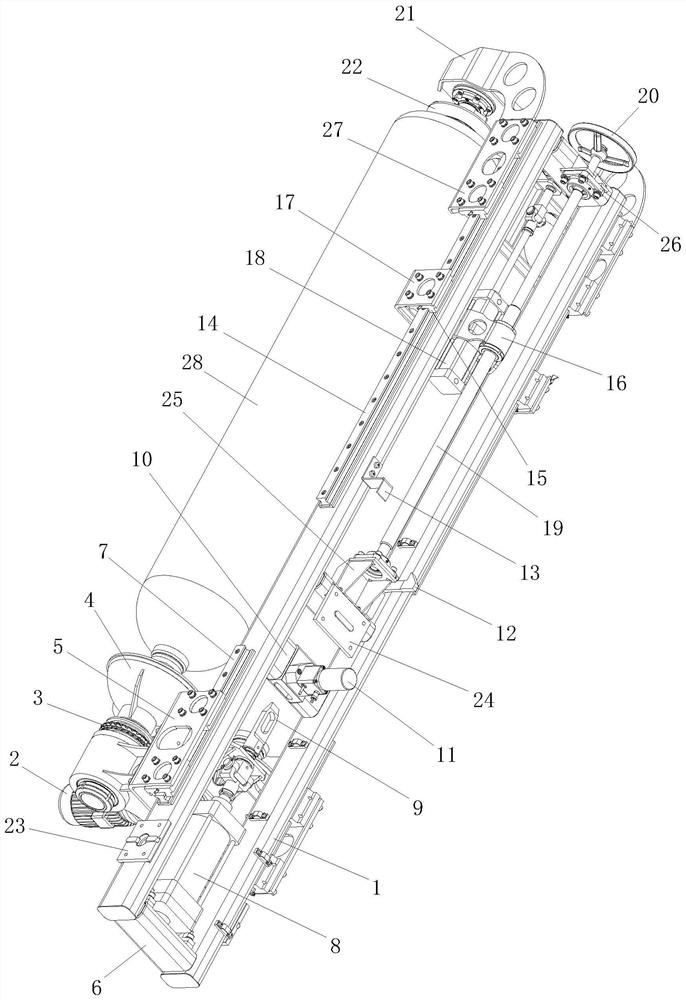

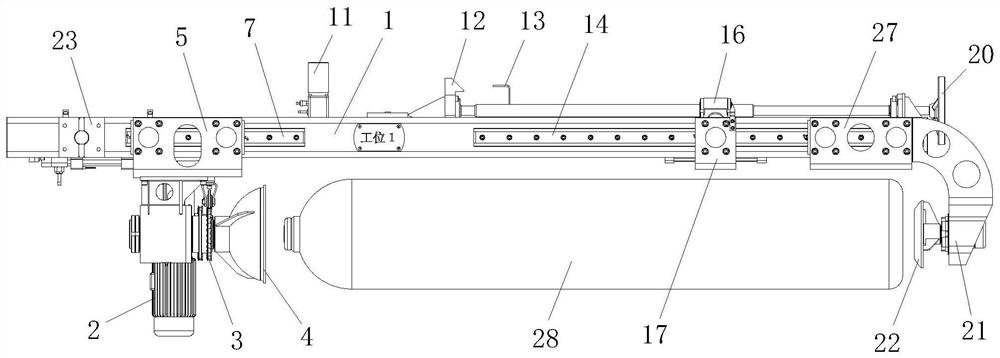

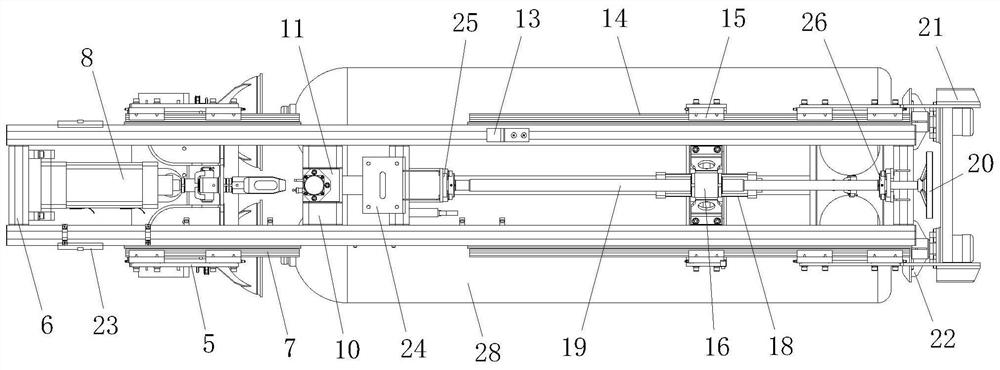

[0022] The present invention will be further described below in conjunction with accompanying drawing by specific embodiment:

[0023] In this example, refer to Figure 1-Figure 5 , the clamping mechanism for a full-automatic internal polishing machine includes a main support frame 1, a rotating motor 2, a rotating tray 4, a propulsion cylinder 8, a compression cylinder 18 and a rear end compression mechanism, and the main support frame 1 Two clamping stations are arranged on the top so that two workpieces 28 can be clamped at the same time; Connect, push the rotary tray 4 and the compression cylinder 18 to push the rear end pressing mechanism through the propulsion cylinder 8, so that the rotating tray 4 and the rear end pressing mechanism respectively press the front and rear ends of the workpiece 28 to realize the clamping of the workpiece 28; The rotating pallet 4 is connected with the rotating motor 2 to form a driving structure for the rotation of the workpiece 28 itsel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com