Novel curing platform

A technology of curing table and platform, applied in the direction of pretreatment surface, coating, device for coating liquid on the surface, etc., can solve the problems of low production efficiency, poor consistency of curing effect, time-consuming and labor-intensive, etc., to improve production efficiency and curing. Excellent consistency and time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

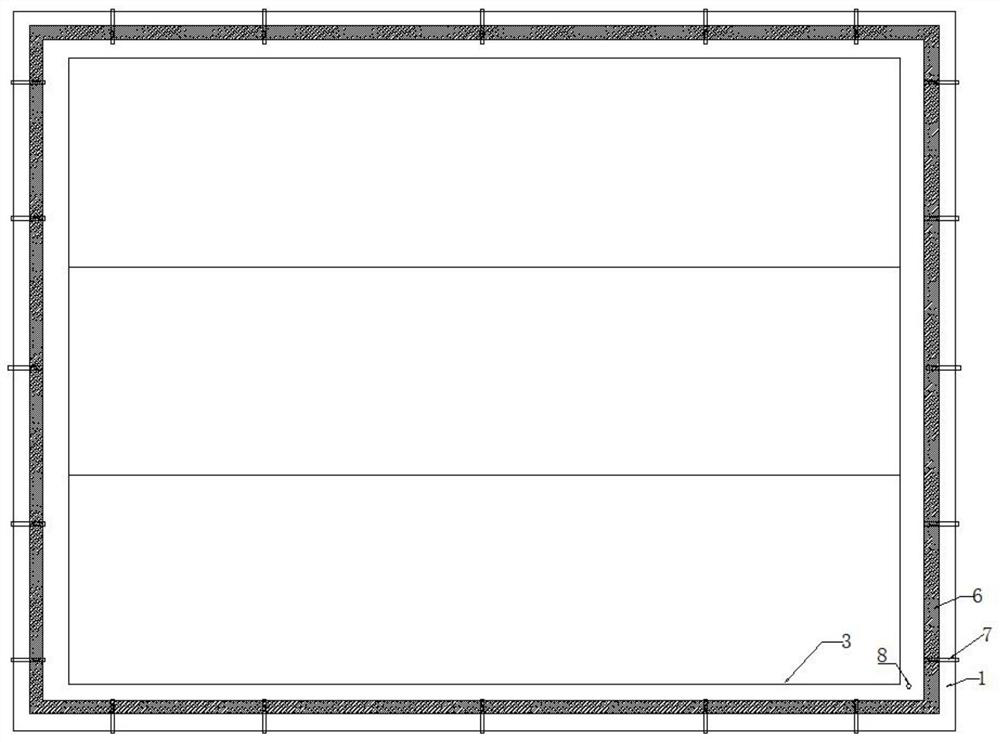

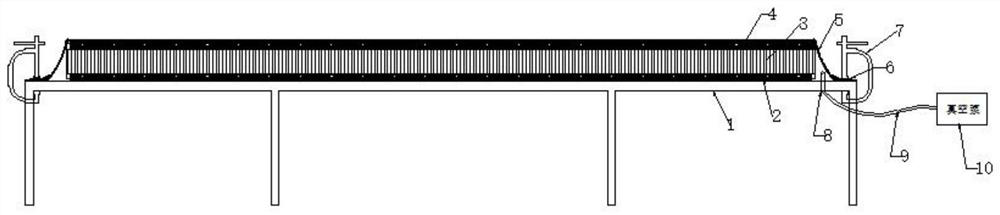

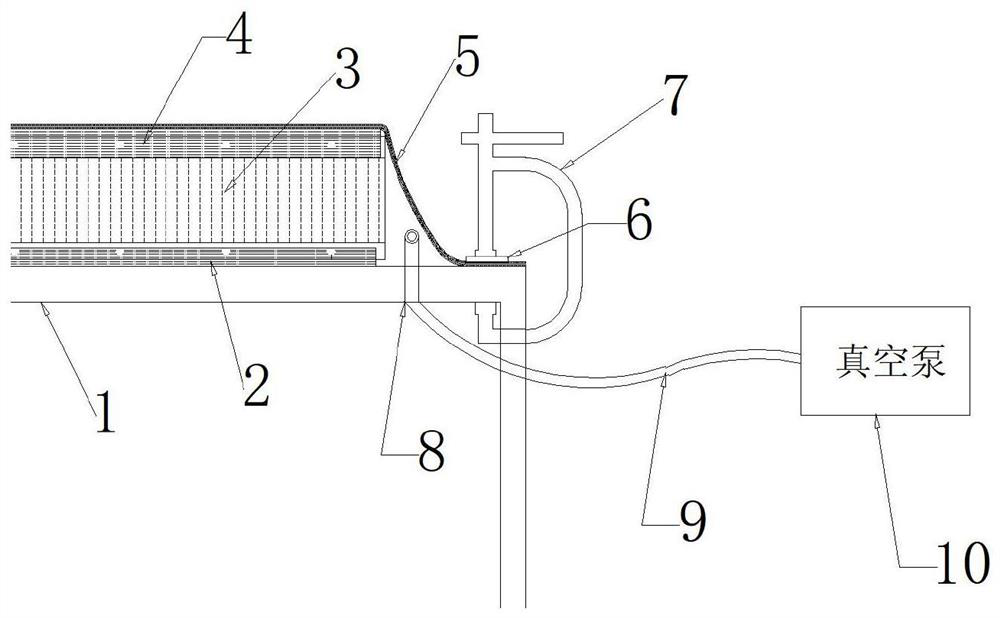

[0022] When the present invention is implemented, a novel curing platform includes a curing platform 1, a backing plate 2 is installed on the curing platform 1, and a modular floating plate 3 is provided on the backing plate 2, and the number of the modular floating plates 3 is several. The top of the modular floating plate 3 is provided with a pressure plate 4, and the top of the pressure plate 4 is provided with a PE film 5. The number of layers of the PE film 5 is two layers. The edge of the PE film 5 rests on the edge of the curing table 1, and the edge of the PE film 5 A fence 6 is placed on the top of the place, and a quick clip 7 is arranged on the top of the fence 6 and the bottom of the curing table 1, and an air exhaust port 8 is installed on the curing table 1 between the quick clip 7 and the modular floating plate 3, and the air exhaust port 8 pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com