Driving rotary sludge scraping device of filtered sludge treatment system

A sludge treatment and rotary scraping technology, which is applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc., can solve the problems of discounted sludge scraping effect, inability to automatically feed the scraper, and single scraping structure, etc. Achieve the effect of reducing the chance of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

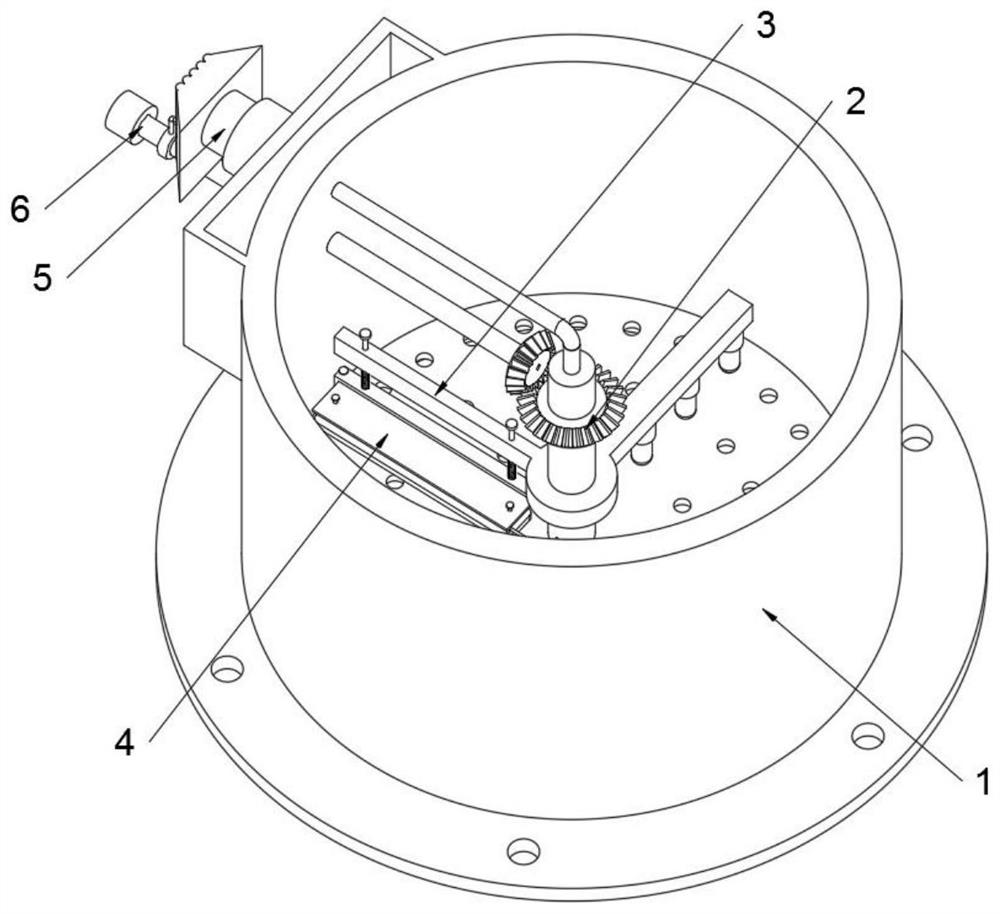

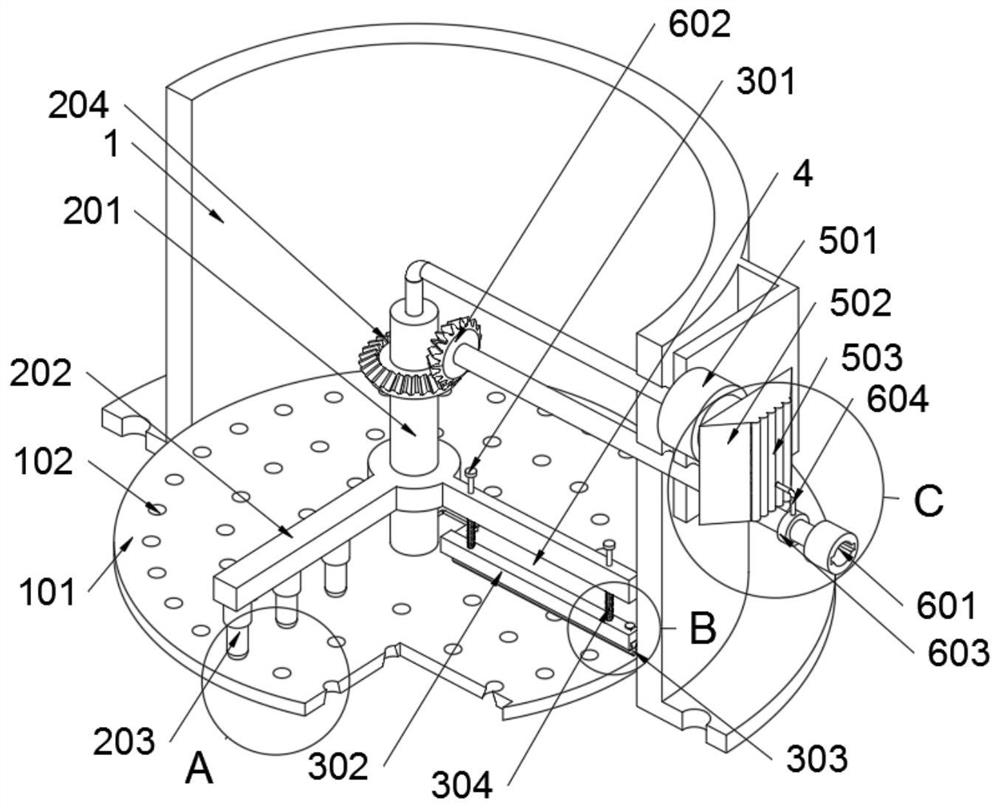

[0033] as attached figure 1 to attach Figure 7 Shown:

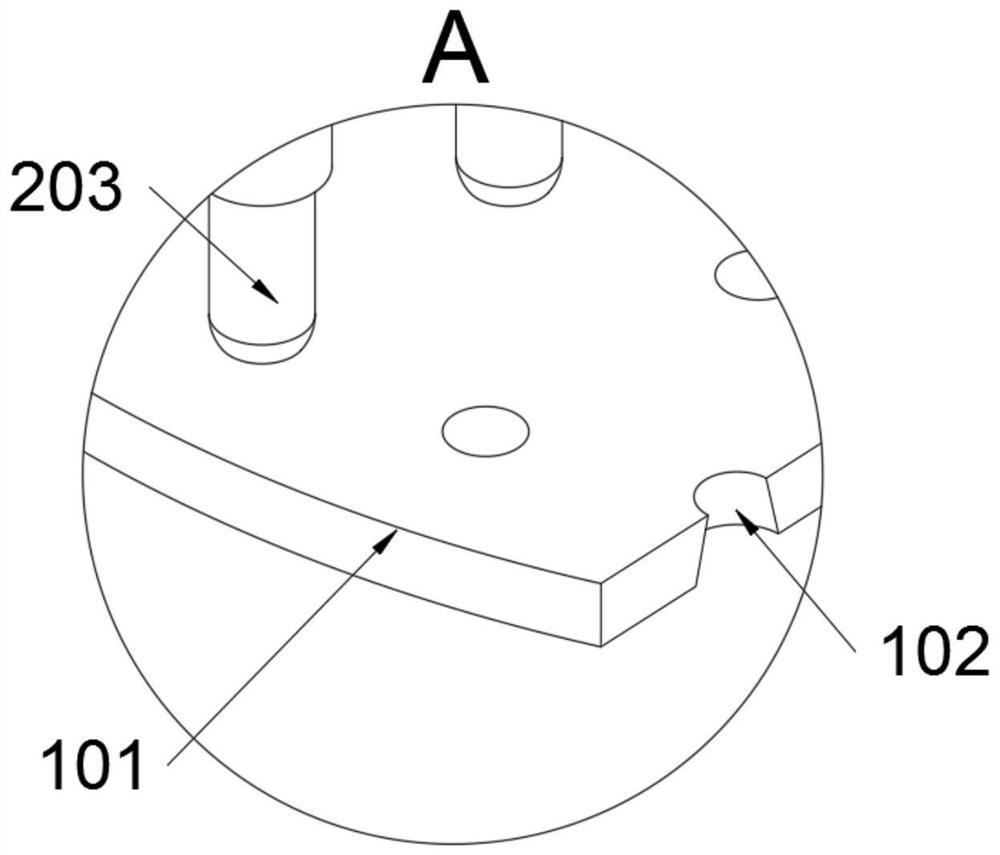

[0034] The invention provides a driven rotary mud scraping device for a filter sludge treatment system, which includes a pipe body 1; a cleaning structure 2 is rotatably connected to the pipe body 1, and a scraping structure 3 is installed on the cleaning structure 2, and the scraping structure 3 An auxiliary structure 4 is installed on it; an air injection structure 5 is installed on the pipe body 1, and a driving structure 6 is rotatably connected to the pipe body 1; refer to as figure 2 with image 3 , the cleaning structure 2 includes a rotating shaft A201, a mounting seat 202 and an elastic telescopic rod 203, the rotating shaft A201 is rotatably connected to the filter plate 101, and the mounting seat 202 is welded on the rotating shaft A201; three elastic telescopic rods 203 are welded on the bottom surface of the mounting seat 202, And the head ends of the three elastic telescopic rods 203 are all hemispheric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com