Normal-temperature fermented milk beverage and preparation method thereof

A normal temperature fermentation and milk beverage technology, applied in dairy products, milk preparations, applications, etc., can solve problems such as long time of confection, high temperature of confection, and oversweet yogurt products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] The thickness of the embedding layer is 0.5mm (the thickness of the embedding layer is related to the amount of sodium alginate and chitosan added, the more the amount added, the thicker the thickness; the less the added amount, the smaller the thickness), the concentration of the unembedded salt solution lower

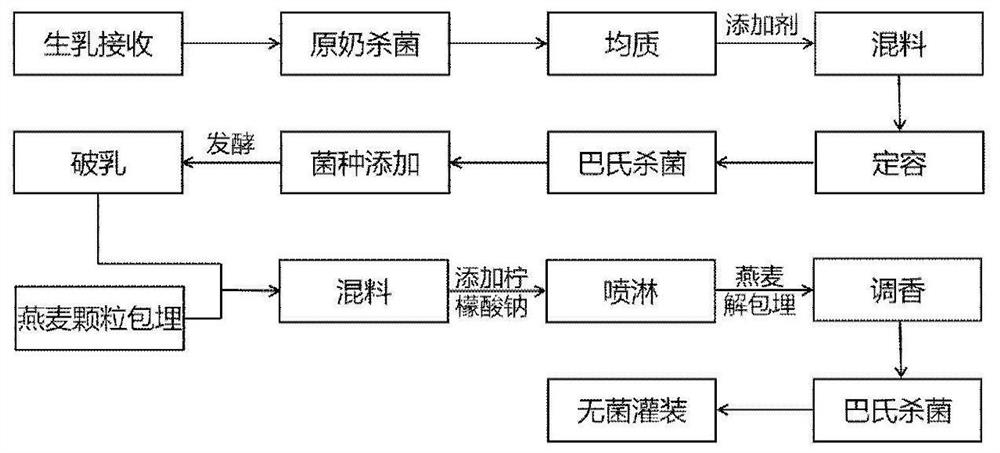

[0092] This implementation involves three main steps:

[0093] The first step is the production of fermented milk ((1)-(8) in the process flow). In all the schemes, there is no difference in the process for fermented milk;

[0094] details as follows:

[0095] 1) Raw milk reception

[0096] When receiving raw milk, it must comply with the relevant requirements and regulations in GB19301-2010. The temporary storage time of raw milk is ≤ 2 hours, and the storage time is ≤ 12 hours. It can be used as fermented raw milk after being filtered with a pore size of 0.5mm. The relevant physical properties of raw milk need to be sampled. Inspection, raw milk that fails...

Embodiment 2

[0125] (The thickness of the embedding layer is 3mm, and the concentration of the unembedding salt solution is higher)

[0126] This implementation involves three main steps:

[0127] The first step, the production of fermented milk ((1)~(8) in the technological process), is identical with the technological process of embodiment 1;

[0128] In the second step, oat granules are embedded ((9)-(10) in the process), the scheme is as follows: cook 1000kg oat granules at 121°C for 10-15min, then lower the temperature to 45-50°C, and chlorinate 5kg Calcium and 0.2kg chitosan were dissolved in 100kg of pure water and added, stirred for 15 minutes, and left to stand for 30 minutes; continue to cool to 20-25°C, and 5kg of calcium chloride and 5kg of sodium alginate were dissolved in 100kg of pure water before adding. Stir for 20 minutes, let it stand for 2 hours, then wash away excess sodium alginate and calcium chloride with pure water, collect the embedded oat granules and store them...

Embodiment 3

[0133] (The thickness of the embedding layer is 1.2mm, and the concentration of the unembedding salt solution is moderate)

[0134] This implementation involves three main steps:

[0135] The first step, the production of fermented milk ((1)~(8) in the technological process), is identical with the technological process of embodiment 1;

[0136] In the second step, oat granules are embedded ((9)~(10) in the process), and different embedding schemes are designed for different embedding layer thicknesses. Cook at ℃ for 10-15min, then cool down to 45-50℃, dissolve 5kg of calcium chloride and 0.2kg of chitosan in 100kg of pure water, add them, stir for 10min, let stand for 40min; continue to cool down to 20-25℃, Dissolve 3kg of calcium chloride and 3kg of sodium alginate in 100kg of pure water, add them, stir for 15 minutes, let stand for 1.5 hours, then wash off excess sodium alginate and calcium chloride with pure water, and collect the embedded oat granules Preserve in sugar d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com