A Method for Optimizing the Structural Parameters of the Winding Area of an Oil-immersed Transformer

A technology of oil-immersed transformers and transformer windings, which is applied in the field of transformers, can solve problems affecting the service life of transformers, and achieve the effect of reducing the temperature of windings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

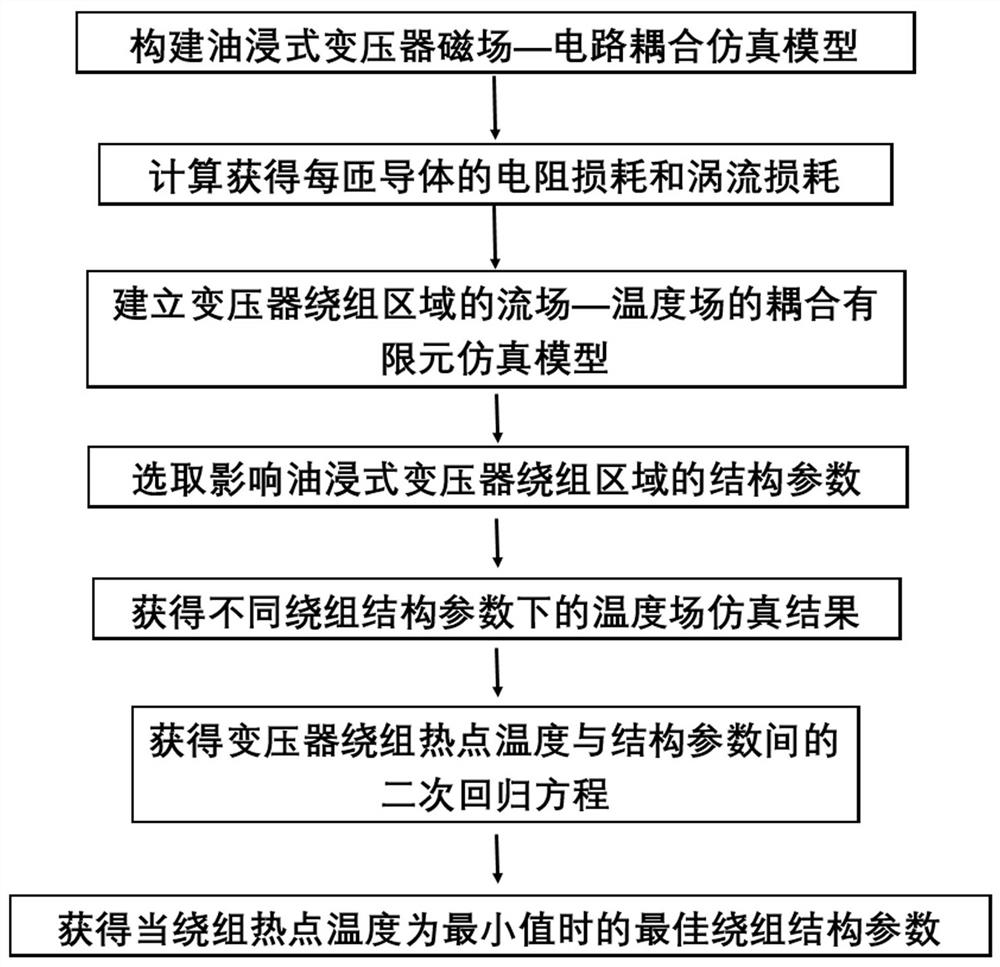

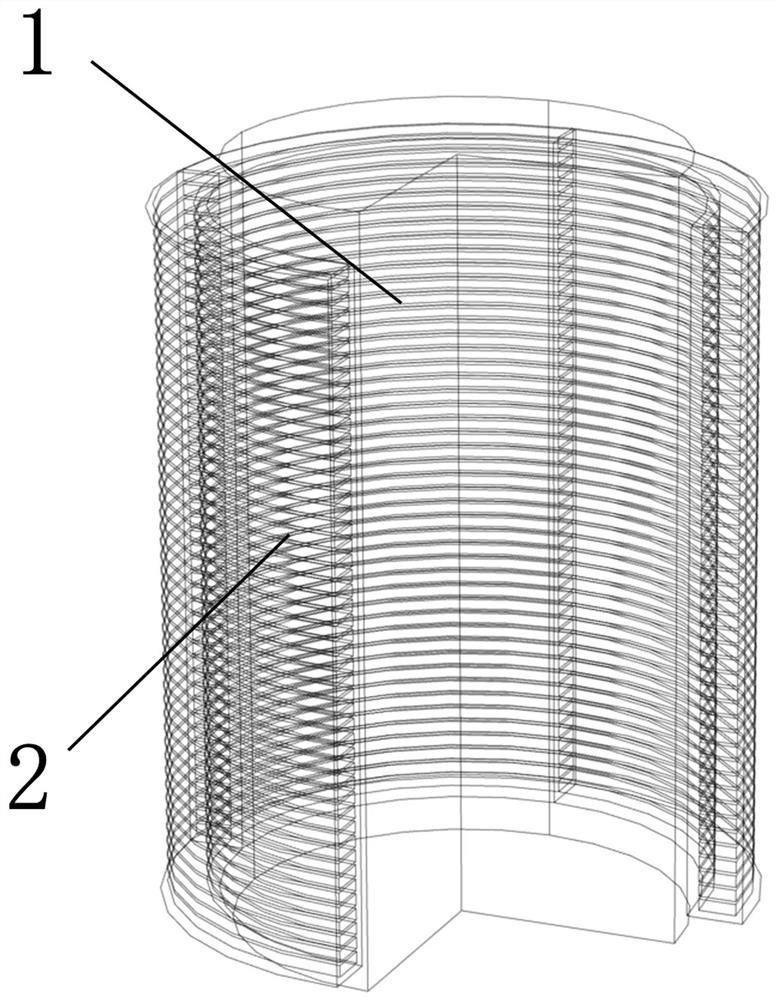

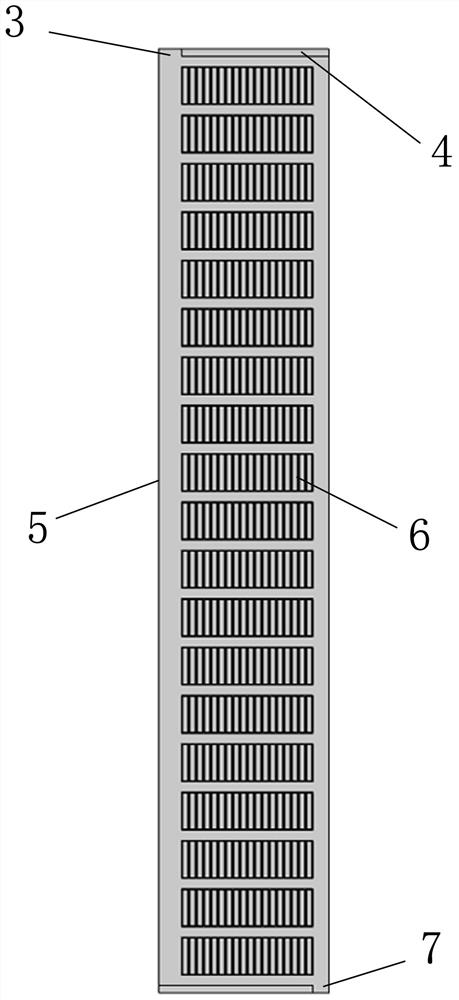

[0032] Such as Figure 1 to Figure 7 As shown, the transformer in the example adopts an oil-immersed transformer, and the optimization method for the structural parameters of the winding area of the oil-immersed transformer includes the following steps.

[0033] Step 1: According to the structure and electrical parameters of the transformer, establish a two-dimensional axisymmetric model; combine the actual characteristics of the iron core, winding metal conductor, insulating material and transformer oil, set the corresponding material properties in the model, and follow the actual operation of the transformer In this case, the field-circuit coupling finite element model of the transformer is established to obtain the current of the conductor in the winding and the distribution characteristics of the magnetic field in the winding area;

[0034] Step 2: Calculate and obtain the resistance loss and eddy current loss of each turn conductor according to the current and magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com