Sensor preparation method, strain grid preparation device and sensor

A sensor and temperature strain technology, applied in the field of sensors, can solve problems such as environmental pollution and difficult degradation of sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

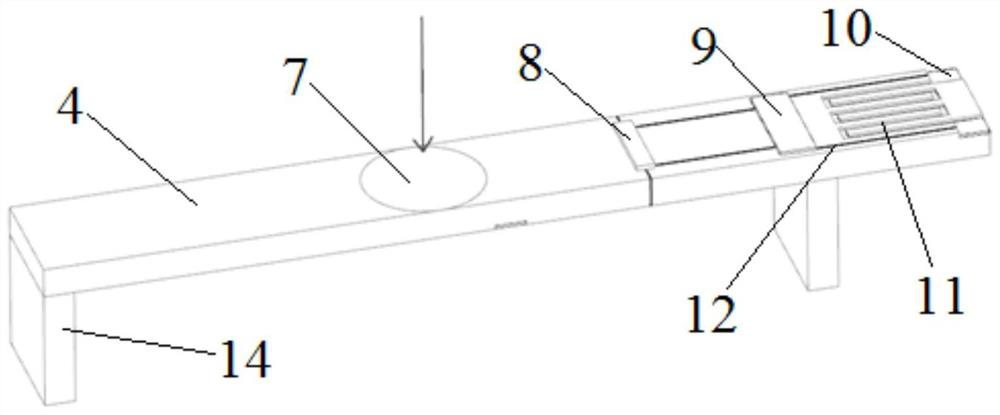

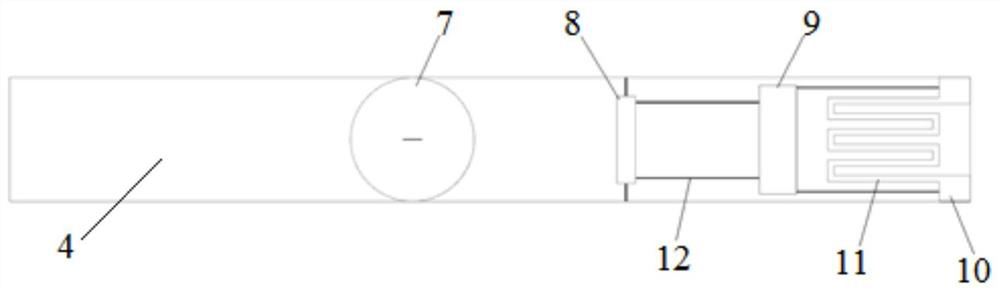

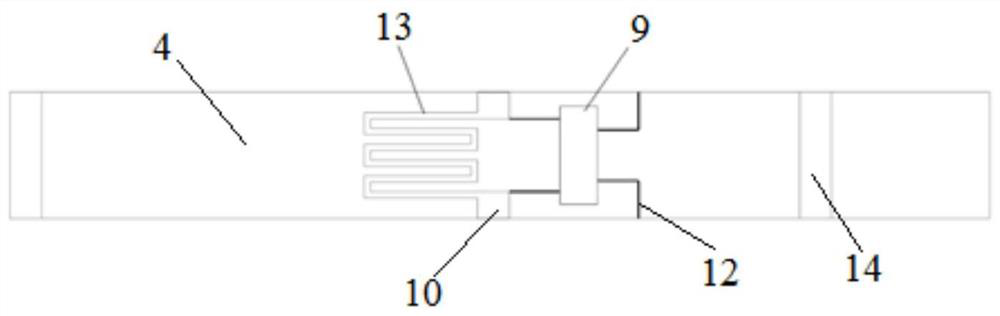

[0048] The preparation process of sensor of the present invention is:

[0049] The prepared wood 4 is processed into a rectangular shape of required size, and placed in a drying oven for 1-2 hours at 50-60° C. to dry.

[0050]Wipe with absolute ethanol on the desired processing position of wood 4 to ensure cleanliness.

[0051] The processed wood 4 is put into the vacuum chamber 2, the vacuum pump 6 and the vacuum valve 5 are opened, and the vacuum degree in the vacuum chamber 2 is controlled by the reading of the vacuum gauge 3 connected to the vacuum chamber 2. When the reading of the vacuum gauge 3 is controlled to 100-200pa, the vacuum valve 5 and the vacuum pump 6 are closed.

[0052] Use the fiber laser 1, turn on the laser, control the change of the Z axis in the five-axis motion laser processing platform, so that the surface of the wood 4 to be processed in the vacuum chamber 2 is located at a distance of 4 mm from the Z axis of the laser focus, and use software to co...

Embodiment 1

[0058] The prepared pine wood is processed into a rectangular shape of the required size, and placed in a drying oven for 1.5 hours at 55°C to dry.

[0059] Wipe with absolute ethanol on the desired processing position of the pine wood to ensure cleanliness.

[0060] The processed pine wood is put into the vacuum chamber 2, the vacuum pump 6 and the vacuum valve 5 are opened, and the vacuum degree in the vacuum chamber 2 is controlled by the reading of the vacuum gauge 3 connected with the vacuum chamber 2. When the reading of the vacuum gauge 3 is controlled to 150pa, the vacuum valve 5 and the vacuum pump 6 are closed.

[0061] Use fiber laser 1, turn on the laser, use a laser with a wavelength of 1070nm and 10KHz pulses, set the laser power to 9.5w, the scanning speed to 95mm / s, and the number of markings to 11 times to control the Z-axis change in the five-axis motion laser processing platform. The surface of the pine wood to be processed in the vacuum chamber 2 is locate...

Embodiment 2

[0065] The prepared pine wood is processed into a rectangular shape of required size, and placed in a drying oven for 2 hours to dry at 60°C.

[0066] Wipe with absolute ethanol on the desired processing position of the pine wood to ensure cleanliness.

[0067] The processed pine wood is put into the vacuum chamber 2, the vacuum pump 6 and the vacuum valve 5 are opened, and the vacuum degree in the vacuum chamber 2 is controlled by the reading of the vacuum gauge 3 connected with the vacuum chamber 2. When the reading of the vacuum gauge 3 is controlled to 200pa, the vacuum valve 5 and the vacuum pump 6 are closed.

[0068] Use fiber laser 1, turn on the laser, use a laser with a wavelength of 1070nm and 10KHz pulses, set the laser power to 10.5w, the scanning speed to 105mm / s, and the number of markings to 13 times to control the Z-axis change in the five-axis motion laser processing platform. The surface of the pine wood to be processed in the vacuum chamber 2 is located at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com