Rotating wheel type heat recovery ventilator

A heat recovery, wheel-type technology, applied in the field of wheel-type heat recovery ventilators, can solve problems such as high energy consumption, loss of cooling air or heating, and inability to maintain indoor air humidity balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

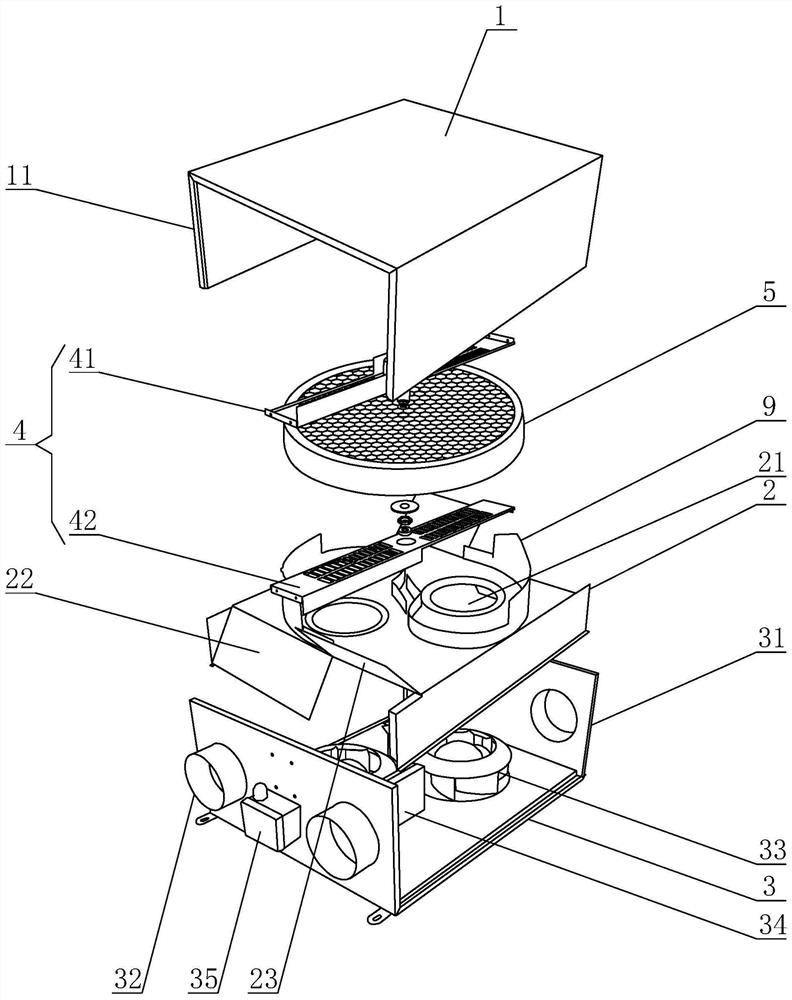

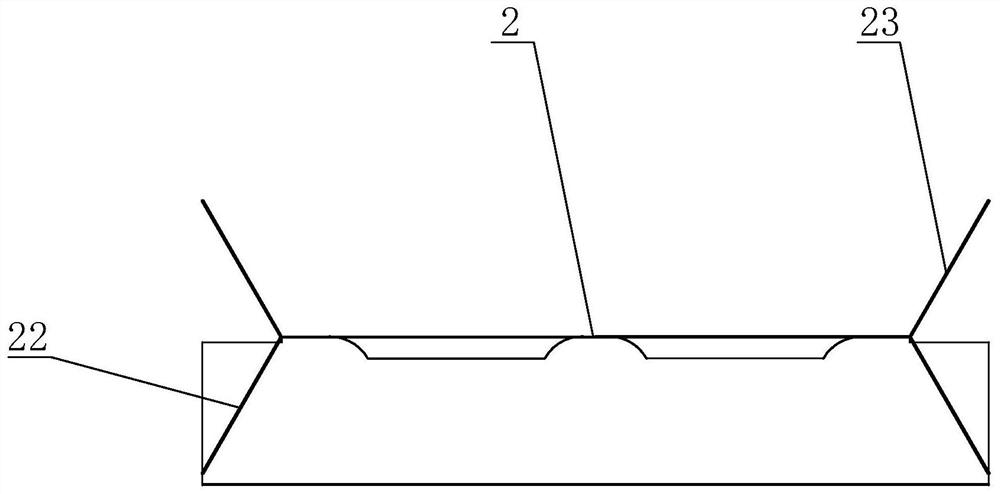

[0035] Example: as attached Figure 1-12 As shown, the present invention is a rotary heat recovery ventilator, including a cover plate 1, a middle plate 2, and a bottom plate 3. The front and rear ends of the top of the bottom plate 3 are provided with vertical plates 31, and the bottom plate 3 and the two Two vertical boards 31 are integrally formed, and the whole is U-shaped. Two vertical boards 31 are provided with two pipe connections 32, and one of the pipe connections 32 is the air inlet end, and the other pipe connection 32 is the air outlet end, preferably , wherein the air inlet end on one of the vertical plates 31 coincides with the axis of the air outlet end on the other vertical plate 31 . The bottom plate 3 is provided with two centrifugal fans 33 , preferably, the centrifugal fans 33 are backward-inclined external rotor centrifugal fans, which are symmetrically installed on the bottom plate 3 . Further, in order to prevent the power cord from leaking out, a junc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com