Design optimization method for buffer structure at entrance of beveled tunnel

A buffer structure and optimization method technology, applied in design optimization/simulation, tunnels, mining equipment, etc., can solve problems such as difficult quality control, difficult construction, and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

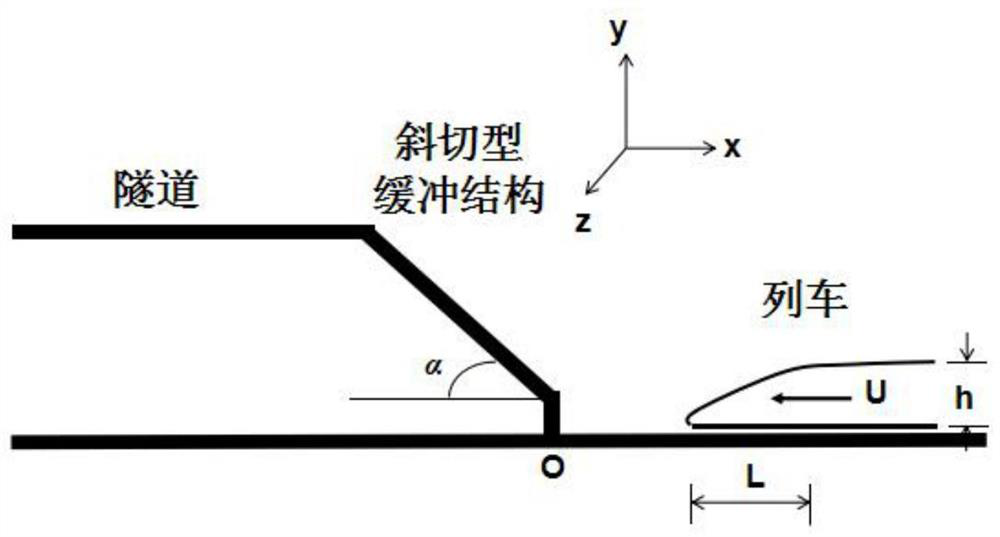

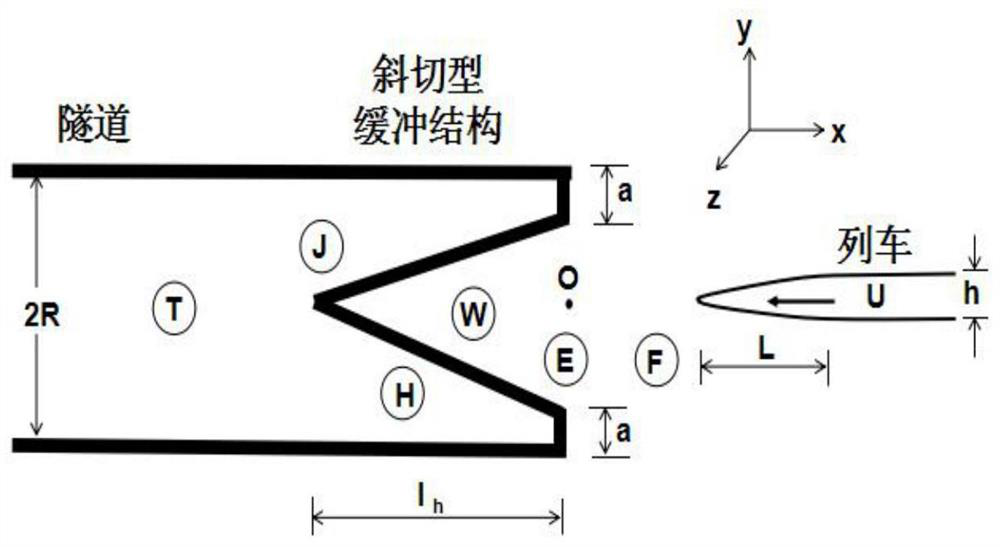

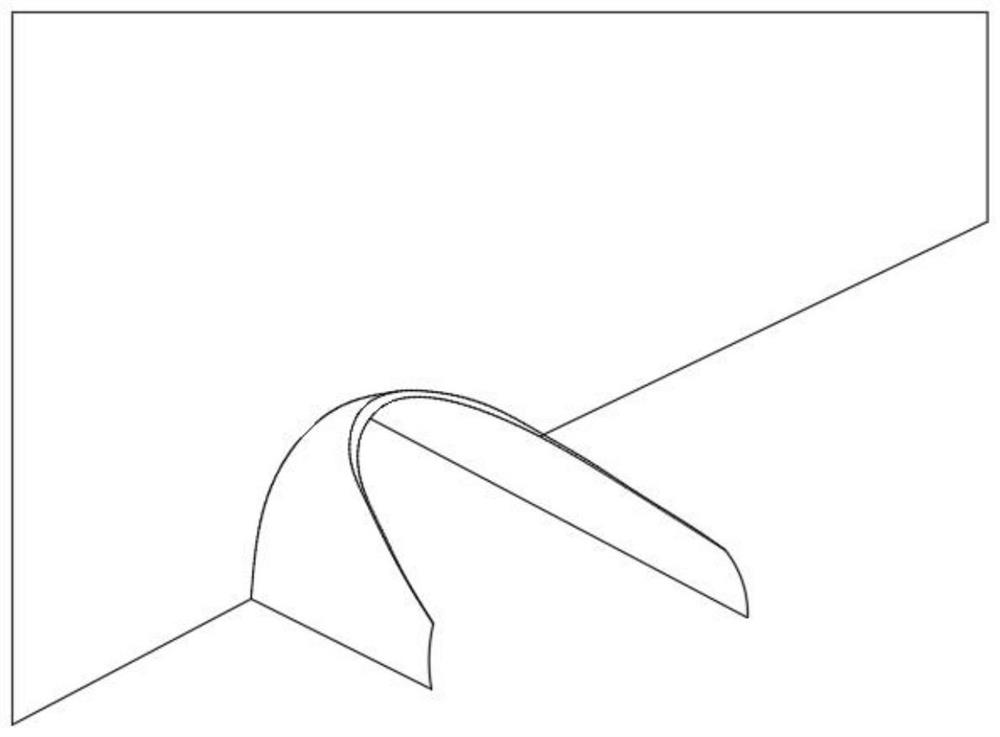

[0105] Such as image 3 with figure 1 As shown, the oblique-cut buffer structure to be designed in the present invention is obtained by cutting an oblique plane forming a certain angle with the buffer structure axis, and after cutting, it becomes a curved-edge arc-shaped structure. The beveled buffer structure is equivalent to a buffer structure provided with infinitely many curved rectangular micropores, and each micropore changes continuously. The method for designing and optimizing the above-mentioned oblique buffer structure of the present invention comprises the following steps:

[0106] S1. Calculation model:

[0107] Such as Figure 1 to Figure 4 As shown, suppose the origin of the coordinates is at point O at the entrance of the buffer structure, the symmetry axis of the train and the tunnel coincides with the x-axis, and the train enters the tunnel at a certain speed U along the negative direction of the x-axis, assuming that the train head length L is ideally stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com